Looking to use 1.5 inch extruded aluminum in your next project? This guide has you covered. We'll walk through the basics, what to look for when buying, how to choose the right profile, and useful accessories. We'll also tackle common issues you might face. Whether you're working on frames, workstations, or displays, this guide will help you get the most out of 1.5 inch extruded aluminum.

What is 1.5 Inch Extruded Aluminum

1.5 Inch Extruded Aluminum refers to aluminum profiles manufactured through the extrusion process, featuring a cross-sectional dimension of 1.5 inches. These profiles, often called 15 series aluminum extrusions in the industry, typically have T-slots on all four sides. The T-slots allow for easy attachment of various components and accessories.

These aluminum profiles are commonly used in constructing frames, workstations, machine guards, and custom fixtures. They offer a balance of strength and lightweight properties, making them suitable for a wide range of applications in manufacturing, automation, and DIY projects.

The standard 1.5" x 1.5" profile usually has a slot opening of approximately 5/16" or 8mm and often comes with a clear anodized finish for enhanced durability. These extrusions are designed to be compatible with components from various manufacturers, providing flexibility in design and assembly.

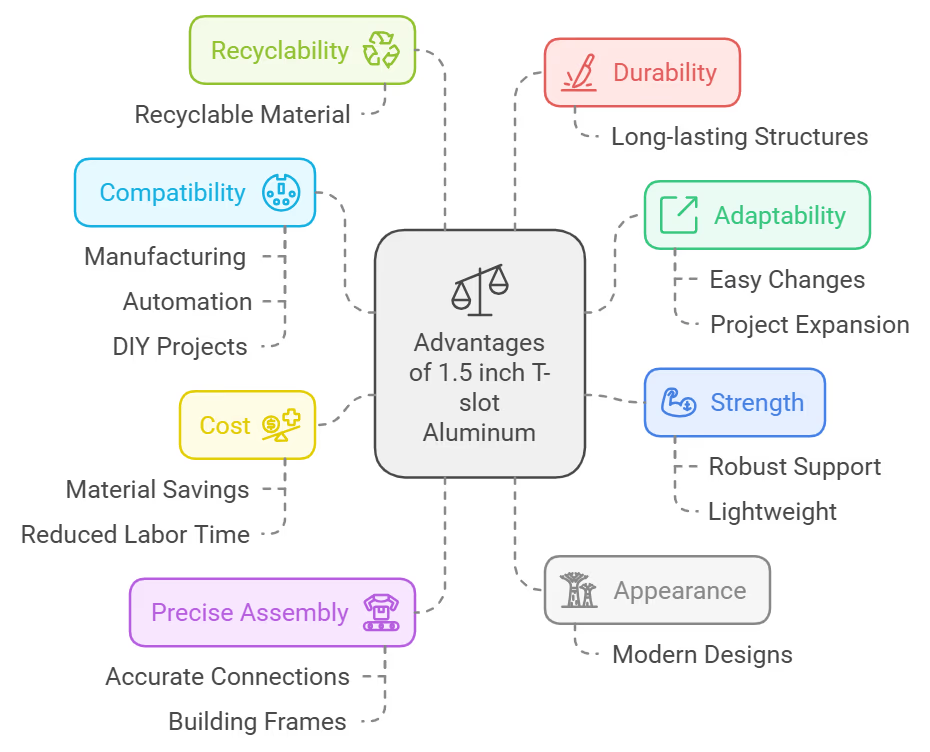

Advantages of 1.5 inch T-slot aluminum

1.5 inch T-slot aluminum offers several practical benefits:

- Adaptability: The T-slot design allows for easy changes to structures. Users can modify or expand their projects without replacing entire setups.

- Strength: These extrusions provide robust support while remaining relatively light. This makes them useful for projects that need to be both sturdy and movable.

- Cost: T-slot aluminum can be reused, potentially saving money on materials. The straightforward assembly process also reduces labor time.

- Compatibility: 1.5 inch T-slot aluminum works with many accessories and parts, making it useful for various projects in manufacturing, automation, and DIY.

- Appearance: The clean look of aluminum extrusions fits well with modern designs.

- Recyclable: Aluminum can be recycled, making it a responsible choice for projects.

- Durability: Aluminum naturally resists corrosion, helping structures last longer.

- Precise Assembly: The T-slot design allows for accurate connections, helpful when building frames, workstations, and other structures.

These features make 1.5 inch T-slot aluminum a practical choice for many applications, from machine guards to custom displays.

Things to Know When Purchasing

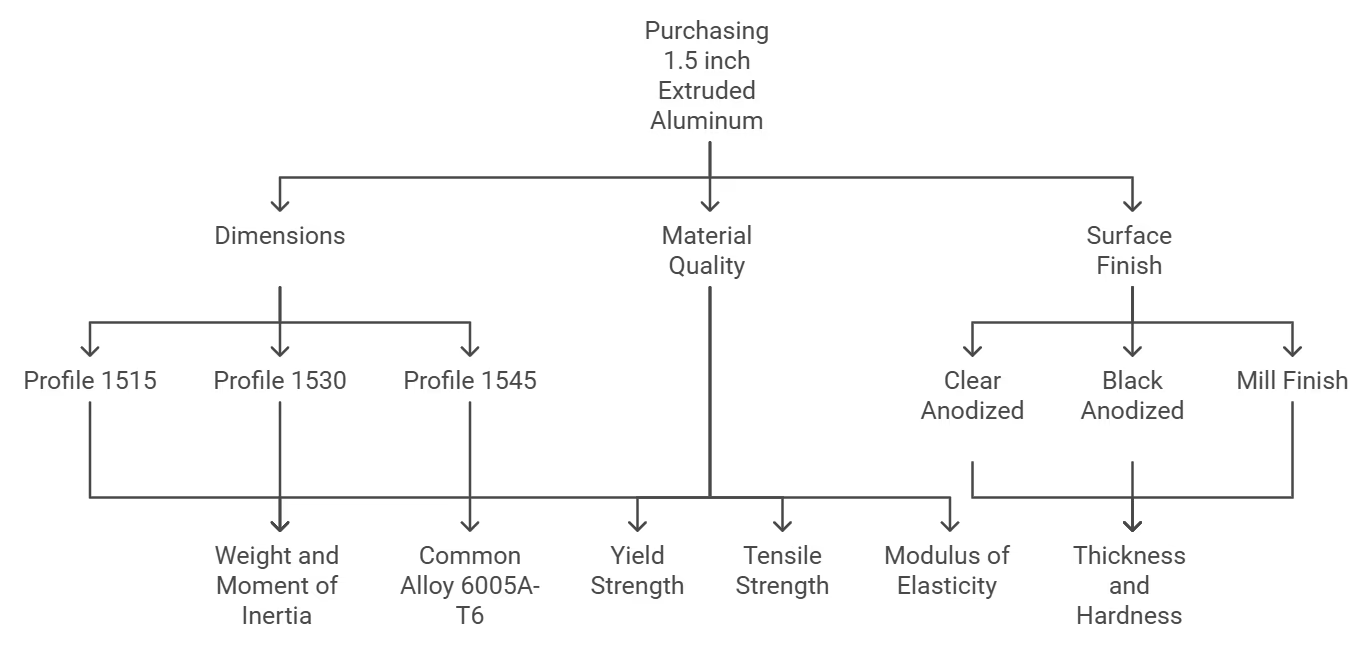

When purchasing 1.5 inch extruded aluminum, there are several key factors to consider:

15 Series Aluminum Extrusion Dimensions

The 15 series aluminum extrusions offer a range of profiles with varying dimensions:

Profile | Dimensions | Weight | Moment of Inertia |

|---|---|---|---|

1515 | 1.5" x 1.5" | 1.438 lbs/ft | Ix = Iy = 0.266 in⁴ |

1530 | 1.5" x 3.0" | 2.876 lbs/ft | Ix = 0.266 in⁴, Iy = 1.597 in⁴ |

1545 | 1.5" x 4.5" | 4.314 lbs/ft | Ix = 0.266 in⁴, Iy = 5.390 in⁴ |

Key dimensional features:

- T-slot width: 0.322" (8.18 mm)

- Inside radius: 0.187" (4.75 mm)

- Slot opening: Approximately 5/16" (8 mm)

Material Quality and Composition

15 series aluminum extrusions typically use high-strength alloys:

- Common alloy: 6005A-T6 or equivalent

- Yield strength: 35,000 psi (241 MPa)

- Tensile strength: 37,700 psi (260 MPa)

- Modulus of elasticity: 10,200,000 psi (70.3 GPa)

The alloy composition includes precise amounts of:

- Silicon

- Iron

- Copper

- Manganese

- Magnesium

- Chromium

- Zinc

- Titanium

Surface Finish and Appearance

Standard surface treatments for 15 series extrusions:

- Clear anodized finish (most common)

- Thickness: 10-15 microns

- Hardness: 250-300 Vickers

- Black anodized finish

- Thickness: 10-15 microns

- Hardness: 250-300 Vickers

- Mill finish (raw aluminum)

These finishes provide:

- Corrosion resistance

- Wear resistance

- Enhanced aesthetic appearance

The anodized surface creates a protective oxide layer, improving the durability and longevity of the extrusion in various environments.

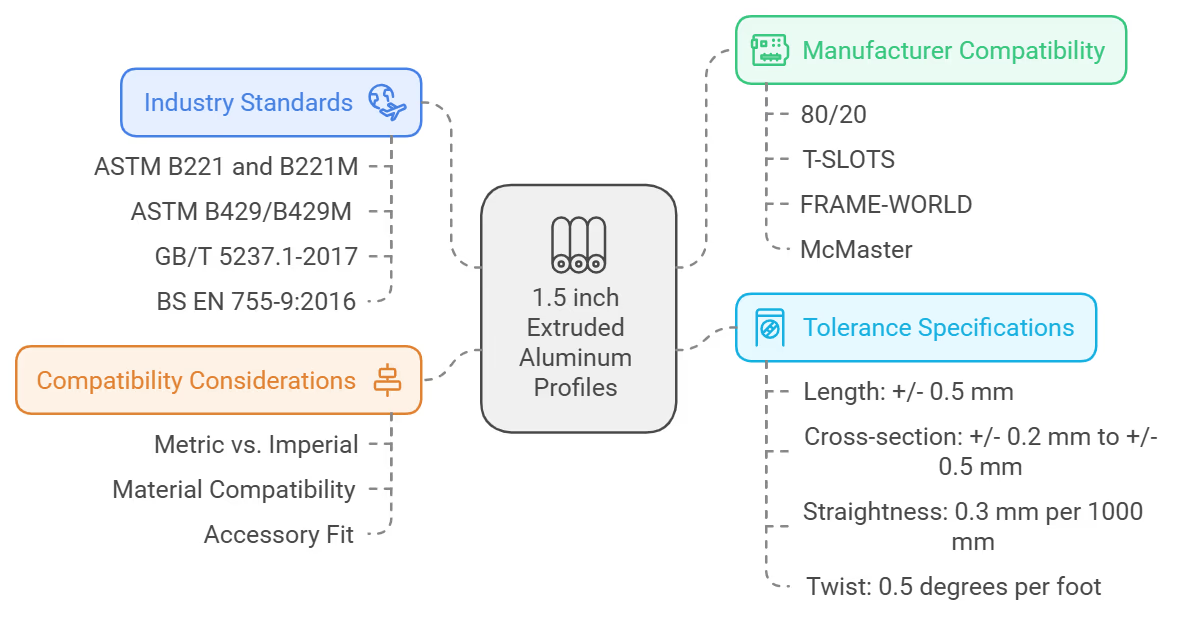

Compatibility and Standards

1.5 inch extruded aluminum profiles are designed to be compatible with various industry standards and components from different manufacturers. This compatibility ensures flexibility in design and assembly across different systems.

Industry Standards

These profiles typically conform to several international standards:

- ASTM B221 and B221M: Standard Specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Wire, Profiles, and Tubes

- ASTM B429/B429M: Standard Specification for Aluminum-Alloy Extruded Structural Pipe and Tube

- GB/T 5237.1-2017: Aluminium alloy extruded profiles for architecture—Part 1: Mill finish profiles

- BS EN 755-9:2016: Aluminium and aluminum alloys — Extruded rod/bar, tube, and profiles, part 9: profiles, tolerances on dimension and forms

Manufacturer Compatibility

1.5 inch (15 series) profiles are often compatible with components from various manufacturers, including:

Manufacturer | Compatible Part Number |

|---|---|

80/20 | #1515-S |

T-SLOTS | #650005 |

FRAME-WORLD | #EX-1 |

McMaster | #60585K104 |

Tolerance Specifications

Standard tolerances for 1.5 inch extruded aluminum profiles typically fall within these ranges:

- Length: +/- 0.5 mm (for lengths up to 3000 mm)

- Cross-section: +/- 0.2 mm to +/- 0.5 mm (profile dependent)

- Straightness: 0.3 mm per 1000 mm of length

- Twist: 0.5 degrees per foot

Compatibility Considerations

- Metric vs. Imperial: It's not recommended to mix metric and imperial profiles in the same assembly.

- Material Compatibility: Aluminum profiles are generally compatible with most materials, but caution should be exercised when using with stainless steel due to potential galvanic corrosion.

- Accessory Fit: Most standard T-nuts, brackets, and connectors designed for 15 series profiles will fit these extrusions, but always verify compatibility before purchasing.

These compatibility features and adherence to standards make 1.5 inch extruded aluminum profiles versatile for various applications across different industries and project requirements.

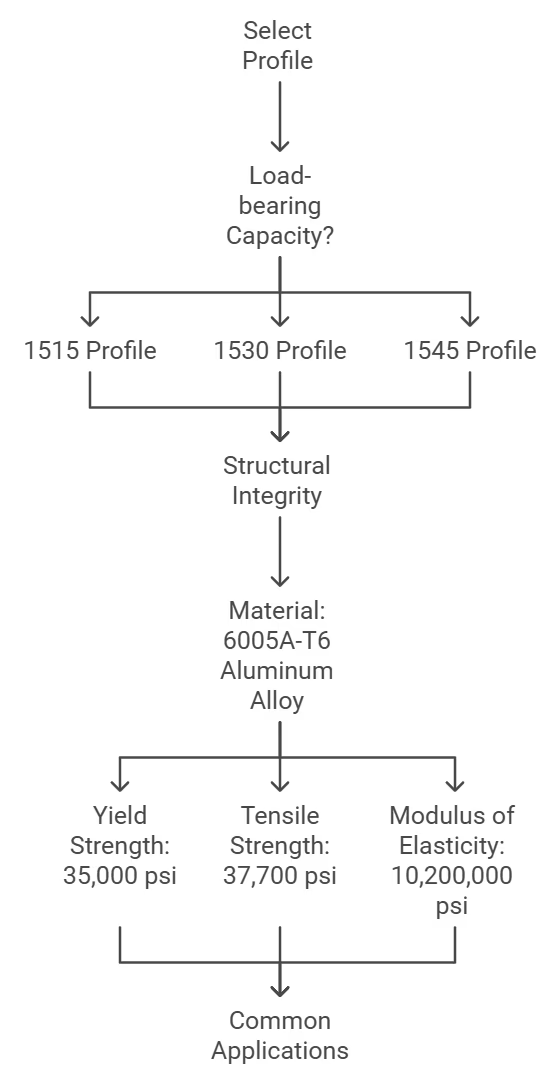

Selecting the Right Profile for Your Project

Load-bearing capacity:

- 1515 profile (1.5" x 1.5"): Moment of inertia Ix = Iy = 0.266 in⁴

- For heavier loads: Use 1530 (1.5" x 3.0") or 1545 (1.5" x 4.5")

Structural integrity:

- Material: 6005A-T6 aluminum alloy

- Yield strength: 35,000 psi

- Tensile strength: 37,700 psi

- Modulus of elasticity: 10,200,000 psi

Common applications:

- Machine guards

- Workstations

- 3D printers

- Displays

- Jigs and fixtures

Accessories and Components

T-nuts and fasteners:

- Use M8 T-slot nuts

- Materials: Galvanized carbon steel, stainless steel

- Slot size: 5/16" or 8mm for 15 series

Connectors and brackets:

- L-shape corner connectors for 90-degree joints

- Various brackets for different connections and loads

Choosing accessories:

- Check compatibility with 15 series profiles

- Verify manufacturer compatibility (80/20, T-SLOTS, etc.)

- Match material and finish with the profile

- Select based on strength and assembly requirements

Use accessories designed for 1.5 inch (15 series) profiles to ensure proper fit and function.

Common Challenges and Solutions

When working with 1.5 inch extruded aluminum, several challenges may arise. Here are some common issues and their solutions:

Dealing with tight tolerances:

- Challenge: Achieving precise dimensions in extruded profiles

- Solution: Work with reputable manufacturers who maintain strict quality control. Specify tolerances only when necessary, as over-specification can increase costs.

Addressing surface imperfections:

- Challenge: Surface scratches, die lines, and blisters

- Solutions:

- Use high-quality billets to minimize surface defects

- Reduce extrusion speeds to prevent excess metal deformation

- Employ coolants like liquid nitrogen to lower temperatures and reduce friction

- Perform regular die maintenance to prevent die lines

Troubleshooting assembly issues:

- Challenge: Misalignment or difficulty in fitting components

- Solutions:

- Use index marks on extrusion surfaces to aid in drilling, punching, and assembly

- Ensure compatibility between metric and imperial components to avoid mismatches

- Choose the appropriate profile size and weight for the intended application

- Consider using corner reliefs when sharp corners are unavoidable

Additional tips for minimizing challenges:

- Avoid knife edges by using rounded corners and generous tapers

- Maintain uniform wall thickness where possible

- Use internal webs or ribs to strengthen hollow extrusions and prevent twisting

- Be cautious with asymmetrical designs, as they can increase the risk of die tongue breaks

By following these guidelines and working closely with experienced manufacturers, many common challenges in extruded aluminum projects can be effectively addressed or prevented.

Frequently Asked Questions

How much does 1.5 inch extruded aluminum typically cost?

The price of 1.5 inch extruded aluminum varies depending on the supplier, quantity, and current market conditions. As of 2024, prices generally range from $0.50 to $0.80 per inch for standard 1515 profiles. For accurate pricing, it's best to request a quote from suppliers directly.

Where can I buy 1.5 inch extruded aluminum?

1.5 inch extruded aluminum is available from various suppliers, including online retailers, industrial supply companies, and local metal distributors. Some popular sources include 80/20 Inc., McMaster-Carr, and Misumi. Always compare prices and shipping costs from multiple vendors.

What is the difference between 15 series and 1515 aluminum extrusion?

There is no difference. "15 series" refers to the product line of 1.5 inch based profiles, while "1515" specifically denotes a 1.5" x 1.5" square profile within that series. Both terms are often used interchangeably in the industry.

Can I use 1.5" x 3" aluminum extrusion in place of two 1515 profiles?

While a 1.5" x 3" profile (often called 1530) can sometimes be used instead of two 1515 profiles, it depends on your specific application. The 1530 profile offers greater rigidity in one direction but may have different mounting options. Consider factors like load requirements and assembly method before substituting.

How does the weight of 1515 aluminum extrusion compare to solid aluminum bar?

1515 aluminum extrusion is significantly lighter than a solid aluminum bar of the same dimensions. A typical 1515 profile weighs about 1.1 to 1.4 lbs/ft, while a solid 1.5" x 1.5" aluminum bar would weigh approximately 2.5 lbs/ft. The hollow design of extrusions provides strength while reducing weight.