A 6cm brass pipe in US size is not a standard dimension, as pipes in the United States are typically measured in inches. The closest match is an NPS 2.5-inch pipe, but there are key differences in diameter, fittings, and compatibility to consider. This guide will explain how a 6cm brass pipe fits into US systems, covering its dimensions, standards, and practical applications.

Dimensions: Understanding 6cm Brass Pipe in US Size

If you’ve ever worked with pipes in both metric and imperial systems, you’ll know that switching between the two can be tricky. A 6cm brass pipe, for example, doesn’t align perfectly with US pipe standards, which are measured in inches. So, how do you figure out the right equivalent size?

Converting 6cm to Inches

Let’s start with the basics: 6cm equals about 2.36 inches. While this seems straightforward, US pipe sizes use something called Nominal Pipe Size (NPS), which doesn’t directly correspond to exact measurements. NPS is based on standard dimensions for inner diameter (ID) and wall thickness, so a pipe labeled “2.5 inches” might actually have an outer diameter closer to 2.875 inches.

For a 6cm brass pipe, the closest match in the US would likely be an NPS 2.5-inch pipe, but this depends on the pipe’s schedule (wall thickness).

Why ID and OD Matter

In the US, pipes are classified by their inner diameter (ID), which determines flow capacity, and their outer diameter (OD), which ensures compatibility with fittings. For brass pipes, OD is especially important, as it determines whether the pipe will fit into standard connections.

- Example: If a 6cm brass pipe has a wall thickness of 1mm, its ID would be around 5.8cm, but the OD would remain 6cm. This is why choosing the right NPS size and schedule is critical.

Schedules and Their Role

The wall thickness of a pipe, or its schedule, affects both the ID and its pressure rating. For instance:

- A Schedule 40 pipe has thicker walls than a Schedule 10, meaning it can handle higher pressures but has a smaller ID.

- When converting 6cm pipes to US standards, understanding the relationship between schedule, ID, and OD helps ensure compatibility.

Standards for Brass Pipes in the US

When working with brass pipes in the US, you should adhere to industry standards. These standards ensure safety, compatibility, and performance, whether you’re installing plumbing, HVAC systems, or industrial pipelines.

Standard | Description | Applicable Use |

|---|---|---|

ASTM B88 | Copper and brass pipes for plumbing | Residential and commercial plumbing |

ANSI B1.20.1 | National Pipe Thread (NPT) standards | Threaded fittings and connectors |

NSF/ANSI 61 | Health effects for drinking water pipes | Potable water systems |

Key Standards

- ASTM B88:

- Covers seamless brass tubing for plumbing and water distribution.

- Ensures durability, corrosion resistance, and compatibility with potable water.

- ANSI/ASME B1.20.1:

- Defines thread dimensions and tolerances for brass pipe fittings.

- Ensures standardization for easy installation and maintenance.

Application-Specific Standards

- Plumbing Systems: Must meet NSF/ANSI 61 to ensure the pipe is safe for drinking water.

- HVAC Systems: Brass pipes in heating or cooling systems often follow ASHRAE guidelines for pressure and temperature compatibility.

Why Standards Matter for 6cm Pipes

For a 6cm brass pipe to work in the US, it must meet these standards to ensure compatibility. For example, a brass pipe used in plumbing must meet NSF/ANSI 61 to avoid leaching harmful substances into drinking water.

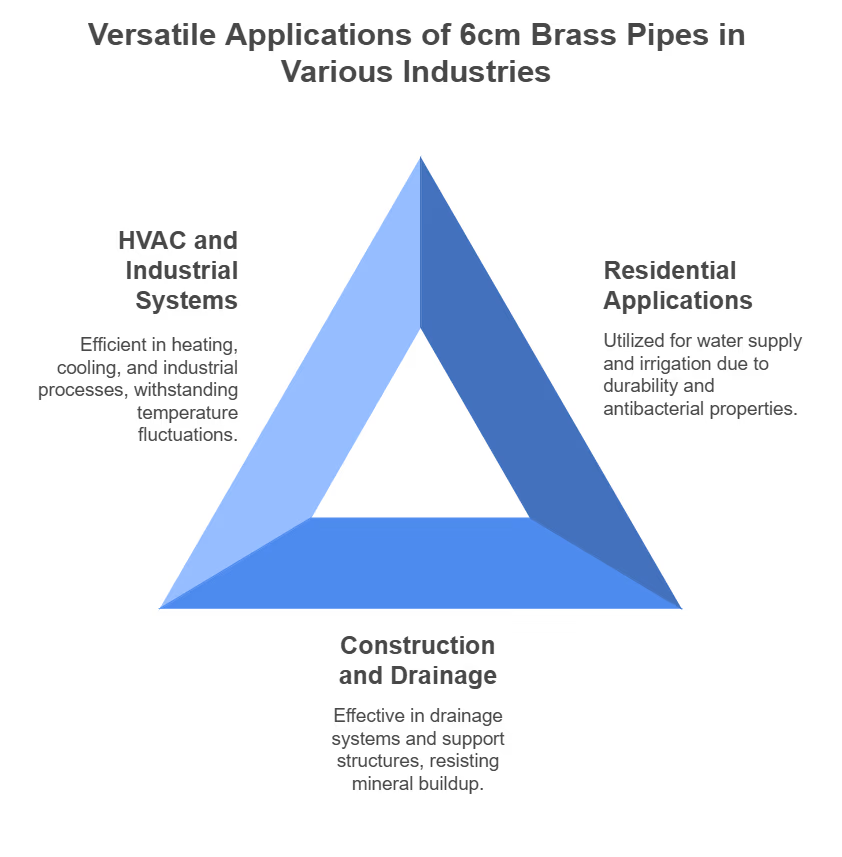

Uses of 6cm Brass Pipes

The 6cm brass pipe stands out as a versatile option across various industries due to its size, durability, and material properties. Whether you’re working on a residential plumbing project or an industrial cooling system, this medium-sized pipe offers a balance of capacity and compatibility.

1. Residential Applications

For homeowners or contractors dealing with plumbing systems, a 6cm brass pipe is often the right size for:

- Water Supply Lines: The moderate diameter allows sufficient flow for household water needs, while brass’s natural antibacterial properties ensure clean, safe drinking water.

- Irrigation Systems: Its resistance to rust and corrosion makes it reliable for outdoor use, such as garden irrigation or small-scale agricultural setups.

Why is 6cm the perfect size? It’s compact enough to fit into tight spaces but large enough to handle steady water flow, making it ideal for medium-sized homes or gardens.

2. Construction and Drainage

In construction, brass pipes are often used for structural or drainage purposes. A 6cm pipe works well in:

- Drainage Systems: Brass’s resistance to mineral buildup ensures long-term reliability for drainage pipes in residential and commercial buildings.

- Support Structures: Lightweight yet durable, 6cm pipes can be used in construction frameworks where corrosion resistance is essential.

3. HVAC and Industrial Systems

In HVAC systems, the 6cm brass pipe’s size and material properties make it a reliable choice:

- Heating and Cooling Systems: Its thermal conductivity allows efficient heat transfer, making it suitable for radiators or heat exchangers in medium-sized residential or industrial systems.

- Industrial Cooling Systems: Brass’s ability to withstand temperature fluctuations ensures reliability in systems that switch between hot and cold fluids.

Material Properties: Why Choose Brass Pipes?

Brass is a tried-and-true material for piping, and its properties make it a top contender in systems requiring durability, safety, and adaptability. Let’s explore what makes brass unique and why it outshines alternatives like PVC, stainless steel, or copper.

1. Corrosion Resistance

Unlike steel, brass doesn’t rust. This makes it ideal for environments where moisture or chemical exposure is a concern, such as water supply lines or HVAC systems. For a 6cm pipe, corrosion resistance ensures long-term reliability, even in demanding conditions.

2. Antibacterial Properties

Brass is naturally antibacterial, inhibiting the growth of bacteria in water systems. This makes it particularly important in drinking water pipelines, where hygiene is critical.

3. Workability and Strength

Brass pipes are easy to cut, bend, and install, saving time during construction. At the same time, they offer high tensile strength, ensuring durability against physical impact or high-pressure conditions.

4. Comparison with Other Materials

- PVC: While PVC is lightweight and cheap, it lacks the durability and heat resistance of brass. Brass pipes won’t crack in extreme temperatures or release toxic fumes in case of fire.

- Stainless Steel: Steel is stronger but heavier and more expensive than brass. For a medium-sized pipe like 6cm, brass provides a better balance of strength, weight, and cost.

By combining durability, safety, and flexibility, brass pipes remain the material of choice for a variety of applications, and the 6cm size is especially versatile for medium-scale projects.

Buying Guide for 6cm Brass Pipe in the US

Finding a 6cm brass pipe in the US can be tricky because metric-sized pipes are not commonly available in the market. But don’t worry—there are practical alternatives and strategies to get the right pipe for your project.

1. Is 6cm Brass Pipe Available in the US?

In most cases, 6cm pipes are not part of standard US inventories, as the market primarily uses imperial measurements. The closest equivalent is an NPS 2.5-inch pipe, which has an outer diameter of approximately 2.875 inches (7.3 cm). This size difference is minimal and often works as a direct replacement.

If you absolutely need a 6cm pipe:

- Check Specialty Suppliers: Look for vendors that cater to metric-sized pipes, often found online or through industrial supply chains.

- Custom Fabrication: Some manufacturers offer custom brass pipes, but this can be more expensive and time-consuming.

2. Alternatives to 6cm Brass Pipe

- NPS 2.5-Inch Pipe: This is the most practical substitute. It’s widely available and compatible with standard US fittings.

- Adapters and Reducers: If the size difference affects your project, use threaded adapters or reducers to ensure a snug fit between pipes.

3. Tips for Buying Brass Pipes

- Measure Twice: Always double-check your required inner diameter (ID) and outer diameter (OD) to ensure compatibility.

- Choose the Right Schedule: For water systems or HVAC, a Schedule 40 pipe is often sufficient, but high-pressure applications may require thicker walls (e.g., Schedule 80).

- Verify Standards: Look for pipes that meet ASTM B88 or ANSI/ASME standards to ensure durability and compliance.

Maintenance and Common Challenges

Maintaining a brass pipe is essential for ensuring long-term performance, especially in systems exposed to water, pressure, or temperature fluctuations.

1. Common Problems

- Corrosion in Aggressive Environments: While brass resists rust, it can corrode in areas with high chlorine or acidic water. This is often seen in swimming pools or industrial systems.

- Mineral Buildup: Hard water can cause lime or calcium deposits, reducing the pipe’s flow capacity over time.

- Thread Damage: Improper installation, such as overtightening fittings, can damage threads and lead to leaks.

2. Practical Maintenance Tips

- Clean Regularly: Flush pipes every six months with a vinegar solution to prevent mineral buildup. Avoid harsh chemicals that may damage the brass.

- Inspect Fittings: Check connections for leaks and reseal threads with Teflon tape if necessary.

- Protect Against Corrosion: Use a protective coating for pipes in harsh environments to reduce corrosion risks.

3. Solutions for Installation Errors

- Use proper tools to avoid overtightening.

- Ensure all fittings and adapters match the pipe’s size and threading standard.

- Consult a plumber for complex installations.

Application Case Studies

To illustrate how 6cm brass pipes excel in real-world applications, let’s examine a few scenarios where their unique properties and size played a critical role. These examples highlight not only the benefits but also the specific challenges solved by using this type of pipe.

Case 1: Residential Plumbing Upgrade

Background: A homeowner in Florida was experiencing reduced water pressure and rust-colored water due to corroded galvanized steel pipes. The household included four family members, and the system had to handle simultaneous showers, laundry, and kitchen use.

Problem:

- The existing steel pipes were corroding, leading to rusty water and frequent leaks.

- Water pressure dropped significantly during peak usage times, particularly when multiple taps were running.

Solution:

- The plumber recommended 6cm brass pipes for the main water supply lines. The medium size ensured adequate flow, while brass’s corrosion resistance prevented future rust issues.

Challenges:

- Connecting the new brass pipes to existing fittings required custom adapters to ensure a snug fit.

- The installation team had to carefully balance water pressure in different zones of the house.

Outcome:

- Water pressure increased by 25%, and the family noticed immediate improvements in water clarity and taste.

- The homeowner reported zero leaks or maintenance issues over the following 2 years, saving approximately $1,200 in potential repair costs.

Case 2: Data Center Cooling System

Background: A small data center in Arizona was struggling with overheating due to frequent coolant leaks in their aging copper pipes. The pipes needed to handle significant temperature fluctuations between day and night, as well as high flow rates.

Problem:

- Copper pipes developed stress fractures under fluctuating temperatures, causing leaks and downtime.

- Repairs were costly and required frequent system shutdowns, affecting server reliability.

Solution:

- Engineers replaced the damaged pipes with 6cm brass pipes, which offered superior thermal conductivity and resistance to temperature changes.

Challenges:

- The installation team had to ensure the new pipes met the existing system’s flow requirements without disrupting operations.

Outcome:

- Coolant efficiency improved by 18%, and system downtime due to pipe issues dropped from 10 hours per month to less than 1 hour.

- The facility saved $4,500 annually in repair and maintenance costs.

Case 3: Chemical Processing Plant

Background: A chemical plant in Texas required a cost-effective piping solution for transporting mildly acidic liquids. Stainless steel was too expensive, and PVC pipes degraded too quickly in the chemical environment.

Problem:

- Frequent pipe replacements disrupted production and increased costs.

- The pipes needed to withstand chemical exposure without leaching harmful substances into the product.

Solution:

- The plant installed 6cm brass pipes in critical sections of the system, where durability and chemical resistance were essential.

Challenges:

- Workers had to ensure that all pipe joints were properly sealed to prevent leaks during high-pressure operations.

Outcome:

- Pipe replacement frequency dropped from every 6 months to once every 3 years, saving over $15,000 annually.

- The brass pipes maintained consistent performance, meeting safety and durability standards.

Conclusion

If you’ve been searching for a reliable and versatile solution for your plumbing or industrial needs, 6cm brass pipes might be exactly what you’re looking for. They combine durability, corrosion resistance, and a manageable size that fits a wide range of applications.

But how do you make the most of them? Start by understanding your system’s requirements. For example:

- If you’re replacing old galvanized steel pipes in your home, brass’s antibacterial properties will ensure cleaner drinking water.

- For HVAC systems, its resistance to extreme temperatures makes it a no-brainer for long-term efficiency.

When it comes to choosing a supplier, don’t settle. Look for ASTM-certified products, ask for samples, and always verify the pipe’s schedule and dimensions against your system’s needs. A little extra effort upfront will save you headaches later.

And don’t forget: maintenance matters. Regular flushing and inspecting your pipes—especially in hard water areas—will help prevent buildup and extend their lifespan. It’s a simple step that pays off in the long run.

From residential plumbing to industrial cooling, 6cm brass pipes have proven their worth time and again. They’re not just pipes—they’re a reliable partner for the systems that matter most.

FAQs about 6cm Brass Pipe in US Size

Is a 6cm brass pipe compatible with US plumbing systems?

Yes, a 6cm brass pipe can work in US plumbing systems with the right fittings or adapters. Metric pipes like 6cm may not match standard US fittings, but threaded reducers or compression fittings can help bridge the gap. Always check the pipe’s inner and outer diameters to ensure proper compatibility.

What is the closest US size to a 6cm brass pipe?

The closest US size is an NPS 2.5-inch pipe, which has an outer diameter of 2.875 inches (7.3 cm). While the sizes are not identical, the difference is small enough for most applications, especially with minor adjustments to fittings.

Where can I find 6cm brass pipes in the US?

Metric-sized pipes like 6cm are rare in the US. You can check specialty suppliers online or consult custom fabricators who produce pipes to order. Alternatively, NPS 2.5-inch pipes are widely available and can be used as a substitute in many cases.

How do I convert a 6cm pipe to a US standard size?

A 6cm pipe converts to approximately 2.36 inches. The best match in US standards is an NPS 2.5-inch pipe, but remember to consider wall thickness (Schedule) as it affects the inner diameter. Use conversion charts to confirm exact dimensions.

What fittings should I use with a 6cm brass pipe?

Metric-threaded fittings are ideal for a 6cm pipe. If you’re connecting to US-standard pipes, use NPT-to-metric adapters or compression fittings. Always verify the threading type to avoid leaks.