The advent of AI in construction takeoff is revolutionizing the way we approach project planning and estimation.

With AI's ability to rapidly analyze blueprints and execute precise takeoffs, the construction industry stands on the brink of a significant efficiency leap. This technology not only promises to save countless hours but also drastically reduces the margin for error in project estimations.

This is not a distant future scenario but today's reality, thanks to AI construction takeoff technologies. For companies like Awisdom Tile Accessories, this innovation aligns perfectly with our commitment to providing high-quality materials and solutions, ensuring our clients can execute their projects more effectively than ever before.

Continue reading to discover how AI construction takeoff is shaping the future of construction planning and how Awisdom Tile Accessories is at the forefront of this transformation, enhancing project outcomes and sustainability.

What is Ai Construction Takeoff?

AI construction takeoff refers to the application of artificial intelligence technologies to automate the process of measuring, quantifying, and estimating materials from construction blueprints or plans. This technology significantly enhances the accuracy, efficiency, and speed of the pre-construction planning phase by leveraging machine learning algorithms and deep learning technologies. AI-powered tools can automatically detect, label, and quantify materials and components depicted in digital drawings, reducing the time required for takeoff from hours to minutes with high accuracy rates.

This automation not only minimizes human errors but also allows estimators to focus on more strategic aspects of project planning and cost estimation. The integration of AI in construction takeoff marks a pivotal shift towards digitization in the construction industry, promoting cost savings, and optimizing resource allocation for projects of all sizes.

The Evolution of Construction Takeoff

The evolution of construction takeoff mirrors the broader trajectory of technological advancement within the construction industry. Initially, takeoff processes were entirely manual, relying on paper blueprints and physical measurements. Estimators spent countless hours poring over drawings, using rulers and calculators to quantify materials. This method was not only time-consuming but also prone to human error, leading to inaccuracies in material estimations and project budgets.

The first significant evolution came with the advent of digital takeoff software in the late 20th and early 21st centuries. This software allowed estimators to work with digital blueprints on computers, using tools to measure lengths, areas, and volumes directly on the screen. Although this shift to digital takeoff reduced errors and improved efficiency, it still required manual input and was dependent on the estimator's expertise and attentiveness.

The introduction of AI into construction takeoff marks the latest, most revolutionary phase in its evolution. AI construction takeoff leverages machine learning algorithms and image recognition technologies to automate the extraction and quantification of materials from digital plans. This leap forward addresses several pain points associated with traditional methods:

- Time Efficiency: AI drastically reduces the time needed for takeoff, processing complex plans in minutes rather than hours or days. This efficiency frees up estimators to focus on other critical aspects of project management and planning.

- Accuracy: Machine learning algorithms improve over time, learning from each set of plans they analyze. This continuous improvement cycle minimizes errors in material quantification, leading to more accurate budgeting and resource allocation.

- Cost Reduction: By improving accuracy and efficiency, AI construction takeoff helps to reduce wastage of materials and ensures that projects adhere to budgets more closely. Fewer errors in the estimation process translate to significant cost savings over the project lifecycle.

- Scalability: AI solutions can easily scale to handle projects of any size, from small residential buildings to large commercial developments, without a corresponding increase in time or labor.

- Integration and Collaboration: Modern AI takeoff tools are designed to integrate seamlessly with other project management and CAD software, facilitating better communication and collaboration among architects, engineers, and contractors.

As of 2024, AI construction takeoff represents the cutting edge of technology in the construction sector, embodying the industry's move towards greater digitization and automation. This evolution from manual to AI-powered processes signifies a paradigm shift in how construction projects are planned, budgeted, and executed, setting a new standard for efficiency, accuracy, and cost-effectiveness in the industry.

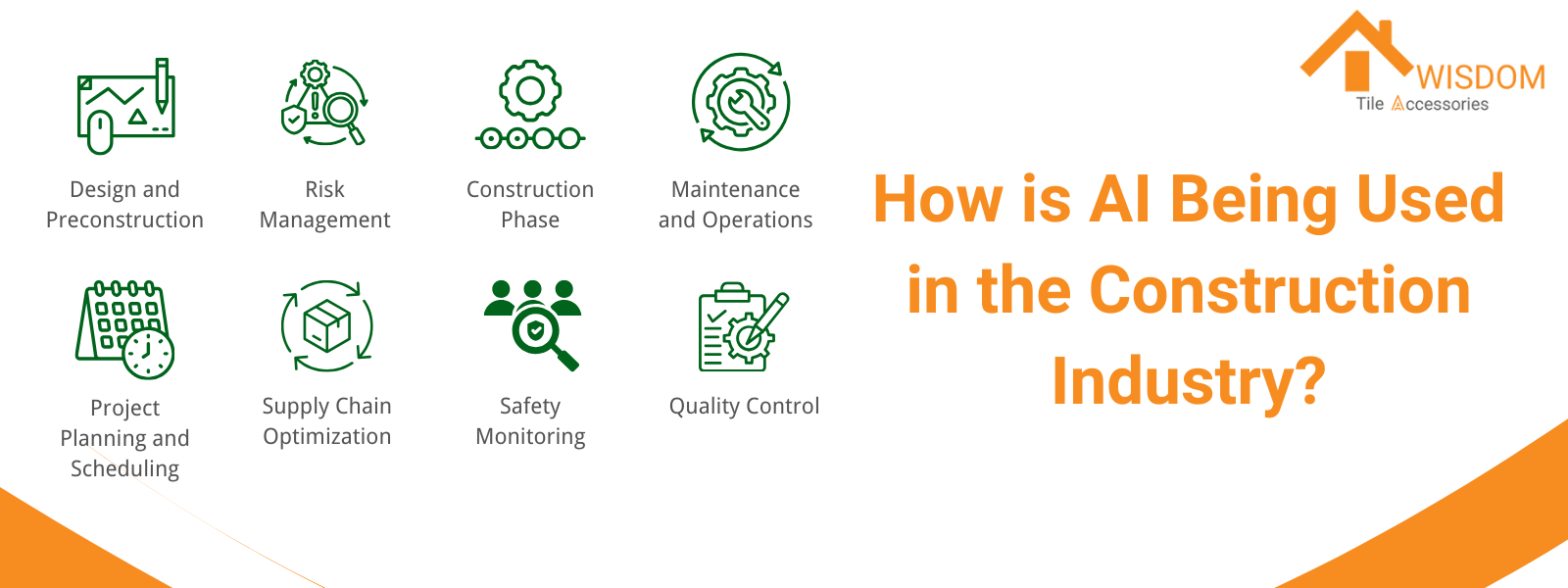

How is AI Being Used in the Construction Industry?

AI's application in the construction industry extends well beyond takeoff, revolutionizing various stages of the construction lifecycle from initial design to post-construction management. Its use cases demonstrate a commitment to enhancing efficiency, safety, and decision-making through data-driven insights. Here's an overview of how AI is currently being used in the construction sector:

Design and Preconstruction

AI assists architects and engineers in the design phase by providing predictive analytics for optimizing building orientation, energy consumption, and material selection. Tools powered by AI can simulate countless design scenarios, evaluating each for cost, time, and environmental impact, thereby informing more sustainable and cost-effective design choices.

Project Planning and Scheduling

AI algorithms analyze historical data to predict project timelines more accurately, identifying potential bottlenecks and suggesting optimal scheduling. This predictive capability helps in allocating resources more efficiently and can significantly reduce the risk of project delays.

Risk Management

Through the analysis of data from various sources, including past projects and real-time inputs, AI models can identify potential risks and propose mitigation strategies. This proactive approach to risk management supports better decision-making and can lead to safer, more reliable project outcomes.

Construction Phase

During construction, AI-powered robots and drones are employed for tasks ranging from bricklaying to conducting site surveys. These technologies increase the precision of physical tasks and can operate in environments that might be unsafe for human workers, thereby enhancing site safety.

Quality Control

AI systems utilize image recognition to monitor ongoing work, comparing it against project plans and specifications to ensure that construction meets the required standards. This continuous, automated quality assurance process helps in early detection of issues, reducing the time and cost of rework.

Maintenance and Operations

Post-construction, AI continues to add value through predictive maintenance of buildings. By analyzing data from sensors installed in structures, AI can predict when parts of a building may need maintenance or repair, thereby extending the lifespan of the building and reducing maintenance costs.

Safety Monitoring

AI algorithms analyze video footage from construction sites in real time to monitor compliance with safety protocols. Identifying unsafe behavior or hazardous situations allows for immediate corrective actions, significantly reducing the likelihood of accidents.

Supply Chain Optimization

AI optimizes supply chain management by predicting demand for materials, tracking inventory levels, and suggesting order quantities. This not only ensures that projects have the materials they need when they need them but also minimizes waste and storage costs.

In 2024, AI's role in the construction industry is integral, driving efficiencies and innovation across all project phases. Its ability to process vast amounts of data and learn from outcomes positions AI as a cornerstone of modern construction management, paving the way for smarter, safer, and more sustainable building practices.

Where Else AI and Construction Are Teaming Up

AI's integration into the construction industry is expanding into various innovative applications beyond traditional project management and takeoff processes. In 2024, this expansion is characterized by several key trends and technologies that are reshaping the sector:

- Mass Timber and Prefabrication: The shift towards more sustainable and efficient construction methods is gaining momentum, with mass timber emerging as a popular material due to its carbon-friendly properties. Prefabrication is also being adopted for its ability to streamline construction processes, although it requires strategic application to balance efficiency with design variability.

- 3D Printing: Industrial 3D printing is on the cusp of transforming construction methods, especially in the domain of startups and experimental projects. This technology offers the potential for innovative construction techniques, including the ability to create complex structures with reduced material waste and increased efficiency.

- AI-Powered Software Solutions: Software solutions specifically designed for the construction industry are incorporating AI to optimize various aspects of project management. For example, ClickUp and OpenSpace.ai offer AI-driven functionalities for construction scheduling, task management, and preconstruction data analysis, enhancing overall project efficiency and accuracy. Procore and Fusion 360 by Autodesk provide comprehensive project management capabilities and AI-driven design tools, respectively, facilitating seamless collaboration and optimized design processes.

- On-Site and Operational Enhancements: AI applications such as Fieldwire and PlanSwift are revolutionizing on-site management and construction cost estimation. These tools leverage AI for real-time data analysis, digital takeoff, and efficient task tracking, contributing to more accurate project planning and execution.

These developments underscore the construction industry's ongoing evolution, driven by AI and technology. The focus on sustainability, efficiency, and innovation is leading to more sophisticated and environmentally friendly construction practices, marking a significant leap forward for the industry as a whole.

How Our Products Enhance AI Takeoff Capabilities

At Awisdom Tile Accessories, we recognize the shift towards AI-driven processes in construction takeoff and project planning. Our range of tile trims, edge trims, stair nosings, and related products is designed to integrate with these technologies, offering precise specifications that AI tools require for accurate estimations.

We supply the construction industry with materials that support AI takeoff's need for detailed product data. This ensures estimations are closely aligned with real-world requirements, minimizing waste and optimizing procurement. Our focus is on providing products that meet the exacting standards of AI-driven planning, aiding in the precise calculation of materials.

Our involvement extends beyond supplying materials. We see our products as part of a larger ecosystem where AI technology enhances project outcomes. By ensuring our product data is easily integrated into AI platforms, we facilitate smoother collaboration among project stakeholders. This approach helps keep architects, engineers, and contractors on the same page, streamlining project execution.

We also align our product innovation with sustainability goals, offering solutions like LED profiles that support green building initiatives. This complements AI takeoff's capability to optimize material usage and supports the construction industry's move towards more sustainable practices.

In summary, our role is to complement AI construction takeoff by providing high-quality, precisely specified products. We aim to make project planning more efficient, support sustainable building practices, and ensure our clients can achieve the best possible outcomes with the help of AI technology.

FAQ about Ai Construction Takeoff

Can AI estimate a construction project?

Yes, AI can estimate construction projects by leveraging large volumes of data and AI techniques to develop company-specific and industry-wide benchmarks, which can reduce biases and inaccuracies in estimates. AI tools help classify unstructured cost data, develop statistical models for estimating, and identify comparable projects for more accurate estimations.

Can AI do takeoffs from blueprints?

AI can perform takeoffs from blueprints with high efficiency and accuracy. By automating the takeoff process, AI-powered software can complete takeoffs in seconds, significantly reducing the time and effort compared to manual and digital takeoffs. This not only speeds up the estimation process but also enhances accuracy, reducing the risk of human error and cost overruns.

How can technology be used to complete constructions?

Technology, particularly AI and machine learning, is used throughout the construction process to automate repetitive tasks, enhance project planning, improve risk management, and optimize resource allocation. AI-powered tools can interpret plans with high accuracy, streamline the preconstruction process, and increase the efficiency and profitability of construction projects by allowing teams to focus on higher-value tasks.

These advancements in AI and technology are transforming the construction industry by making project estimation and execution more efficient, accurate, and profitable.