LED strip lights offer a practical solution for modern lighting needs. They are adaptable and can enhance various spaces. Using aluminum profiles during installation provides protection and improves the overall look. This guide will walk you through the process of installing LED strip lights with aluminum profiles.

Selecting the Right Components

When installing LED strip lights with aluminum profiles, selecting the right components is crucial for achieving the desired lighting effect. Here are key considerations to guide your choices.

Choosing LED Strip Lights

Start by determining the purpose of your LED strip lights. Are they for practical lighting in a workspace or decorative lighting in a living area? For practical use, consider strips with higher brightness, typically over 2000 lumens per meter. These provide sufficient illumination for tasks. For decorative purposes, strips around 1000 lumens per meter may suffice, creating a softer ambiance.

Next, evaluate the color temperature of the LED strips. Options typically range from warm white (2200K - 3000K) for cozy environments to cool white (4000K and above) for areas needing bright visibility, such as offices. Natural white (around 4000K) is often used in kitchens and workspaces to mimic daylight.

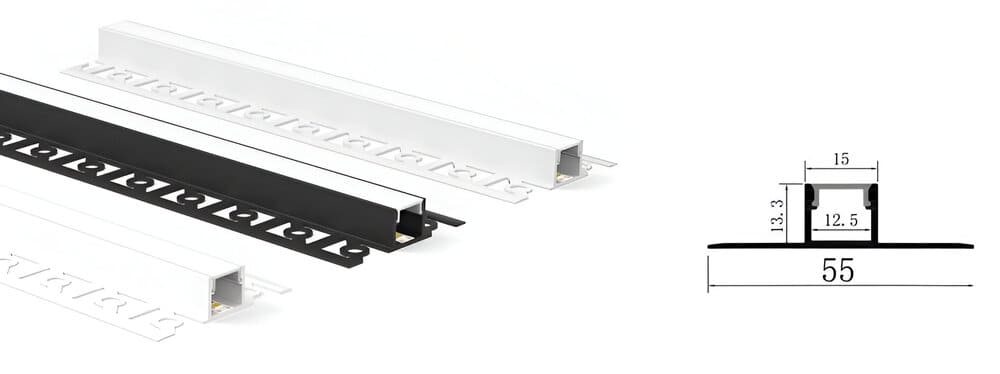

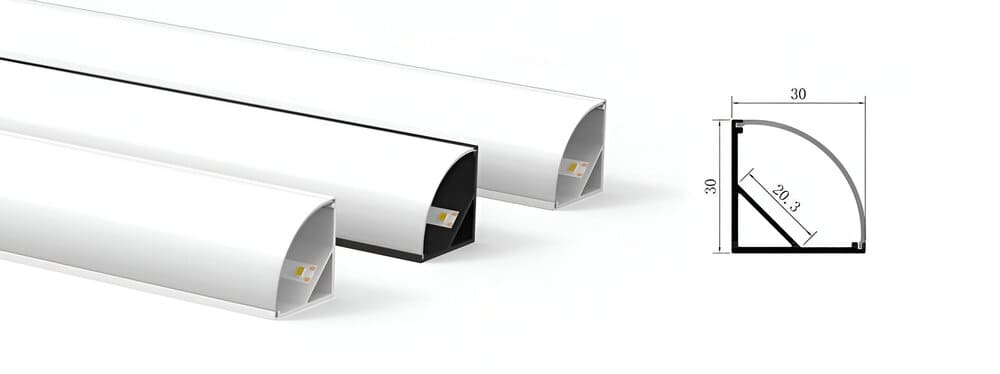

Selecting Aluminum Profiles

Choosing an appropriate aluminum profile enhances both functionality and aesthetics. First, confirm the dimensions of your LED strip. The width of the strip should fit comfortably within the profile to ensure proper installation and light diffusion.

Additionally, think about the type of diffuser you will use. An opal diffuser can help distribute light evenly and reduce hotspots, while clear diffusers are better for applications requiring direct lighting.

Installation Location

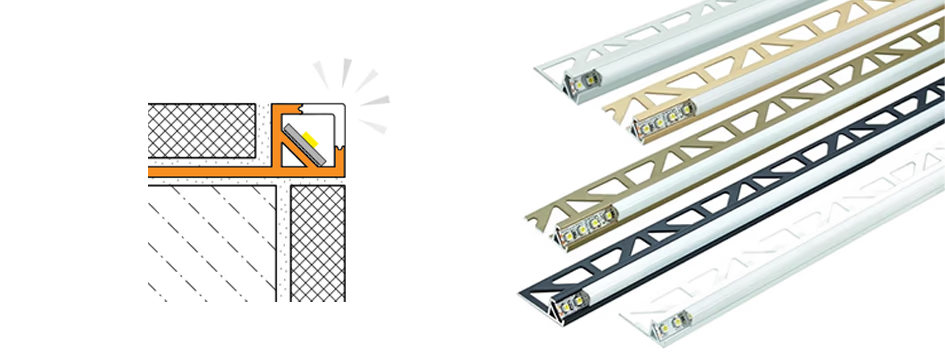

The location where you plan to install the profiles also influences your choices. For outdoor installations, opt for waterproof profiles rated at IP65 or higher. If you need corner lighting, consider corner profiles designed specifically for that purpose.

Installation Process

Planning Your Installation

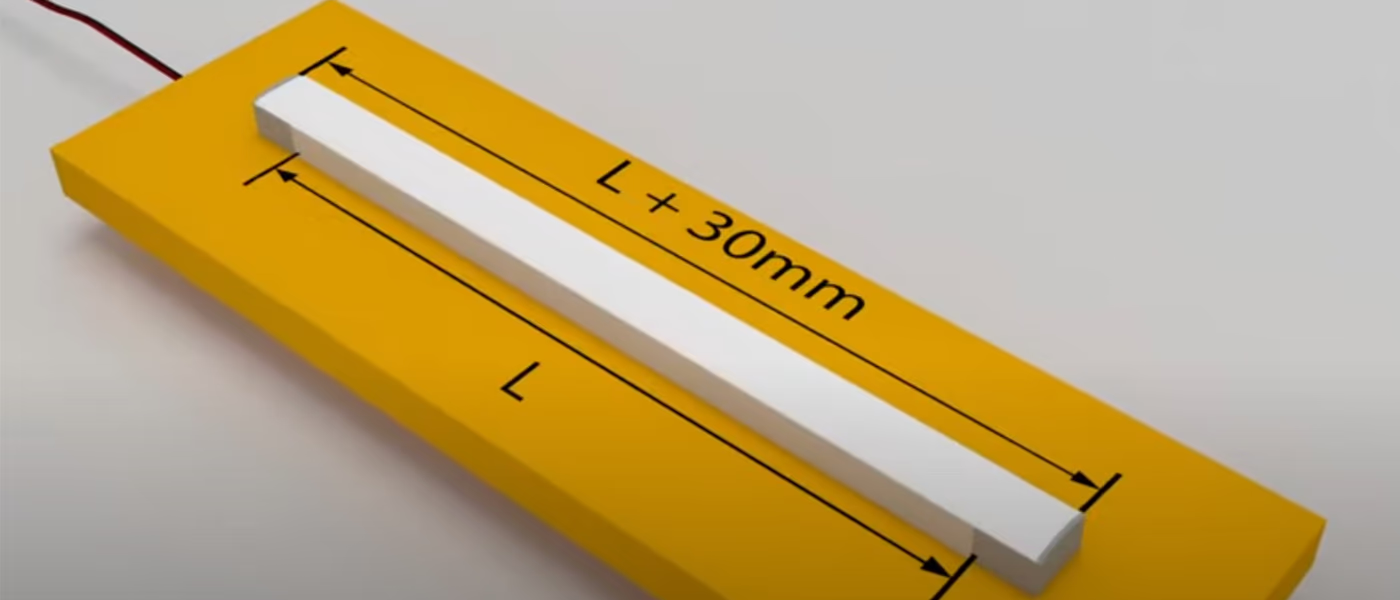

Begin by determining the exact location for your LED aluminum profiles. Measure the length of the area, taking into account any corners or turns. Choose the profile type that best suits your needs, whether surface-mounted or recessed.

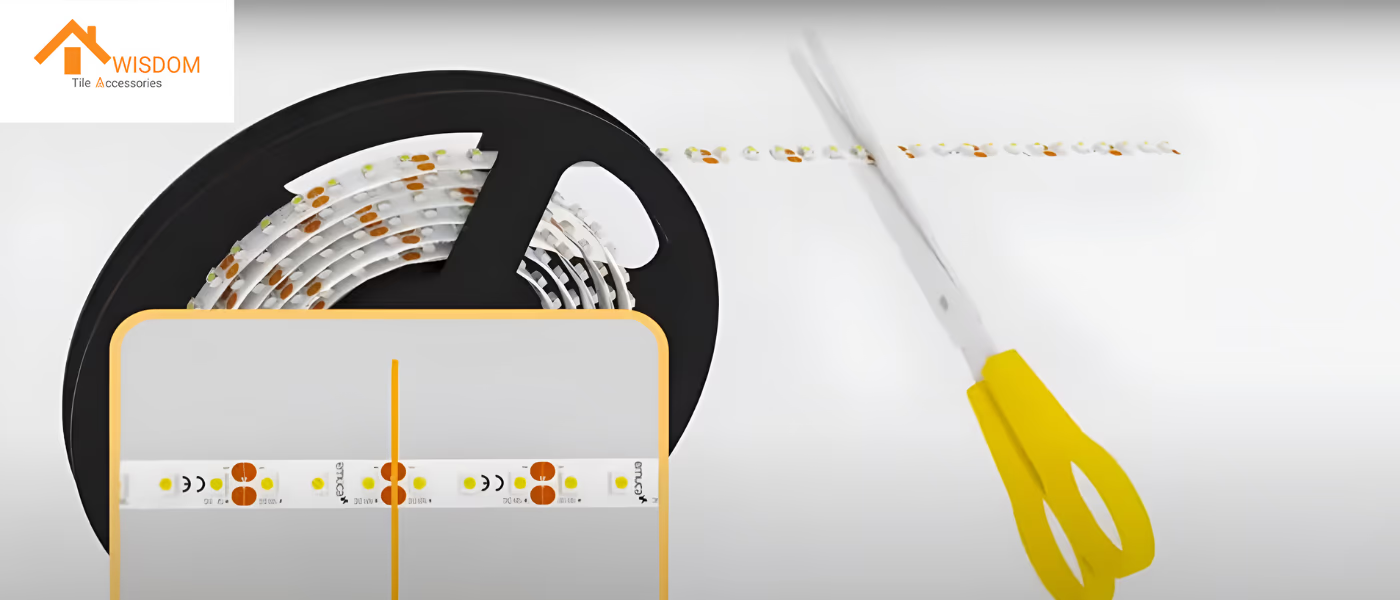

Cutting the Profile and LED Strip

Use a hacksaw to cut the aluminum profile to your desired length. Make sure to cut cleanly to avoid sharp edges. Next, cut the LED strip light to size, ensuring you only cut at designated points on the strip to prevent damage.

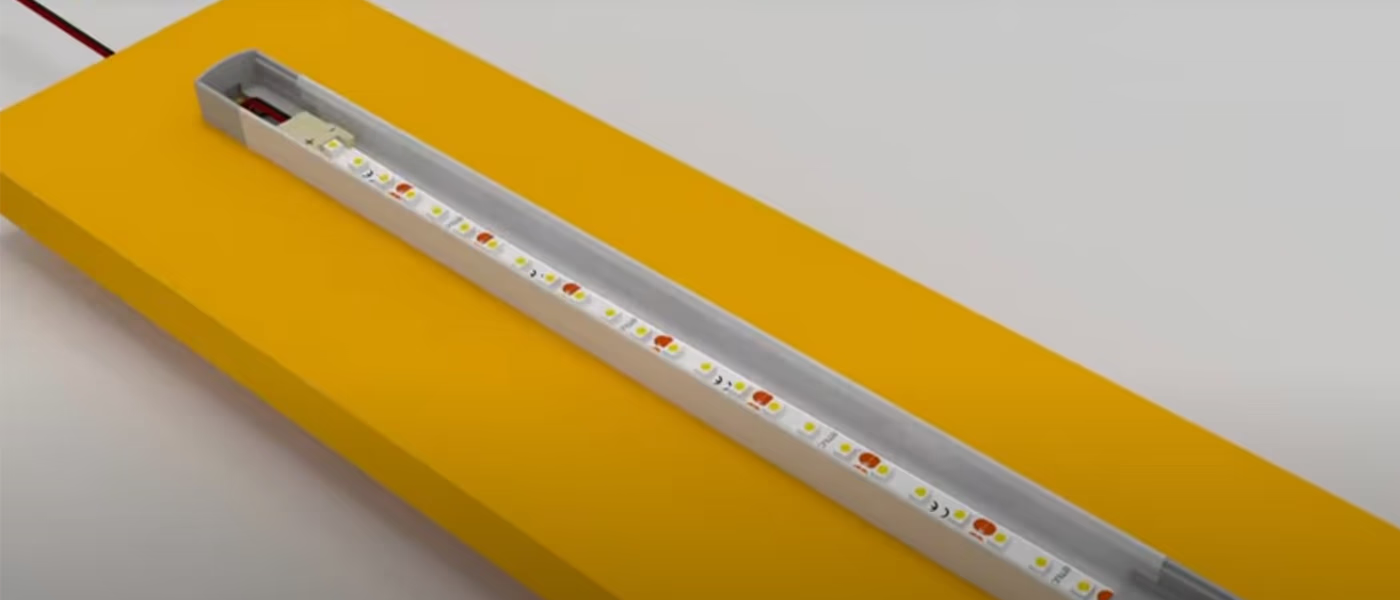

Attaching the LED Strip to the Profile

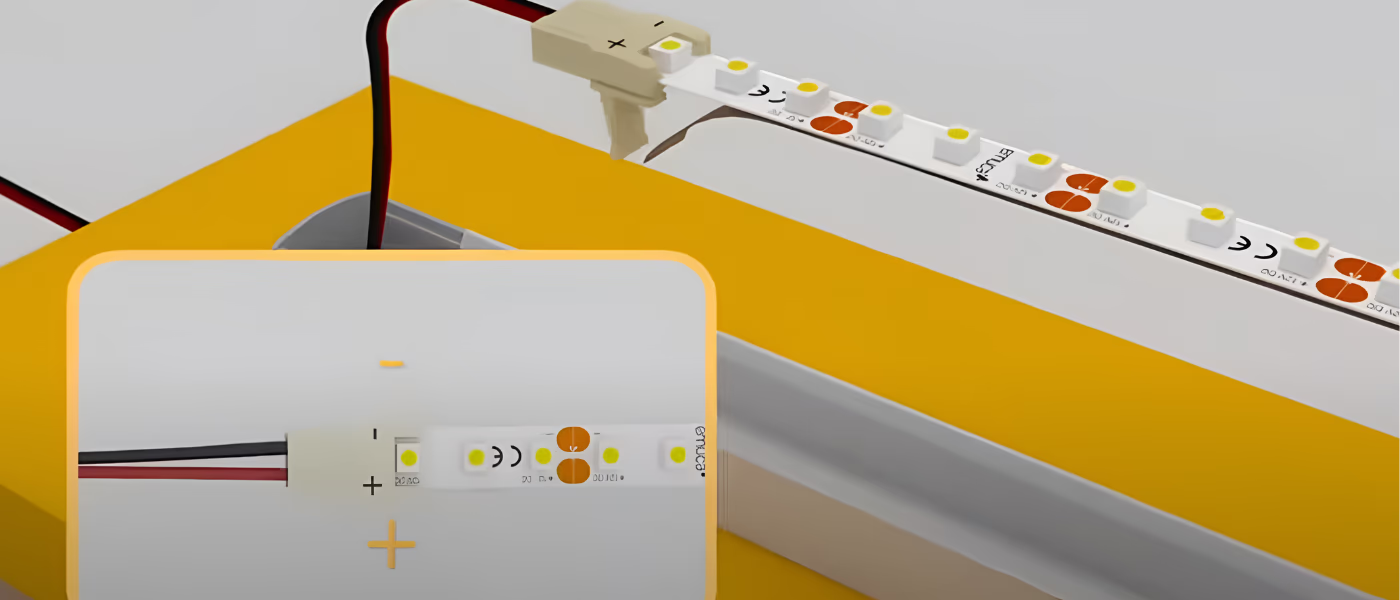

Peel off the adhesive backing from the LED strip light. Carefully press it into the channel of the aluminum profile, ensuring it is straight and securely attached. Apply light pressure while adhering to avoid damaging the strip.

Mounting the Aluminum Profile

Secure the aluminum profile in place using mounting clips or screws, depending on your chosen profile type:

Installing Diffusers and End Caps

Once the profile is mounted, slide or click on the diffuser cover. Choose between clear, frosted, or opal diffusers based on your desired lighting effect. Finally, install end caps on both ends of the profile to protect the LED strip and provide a finished look.

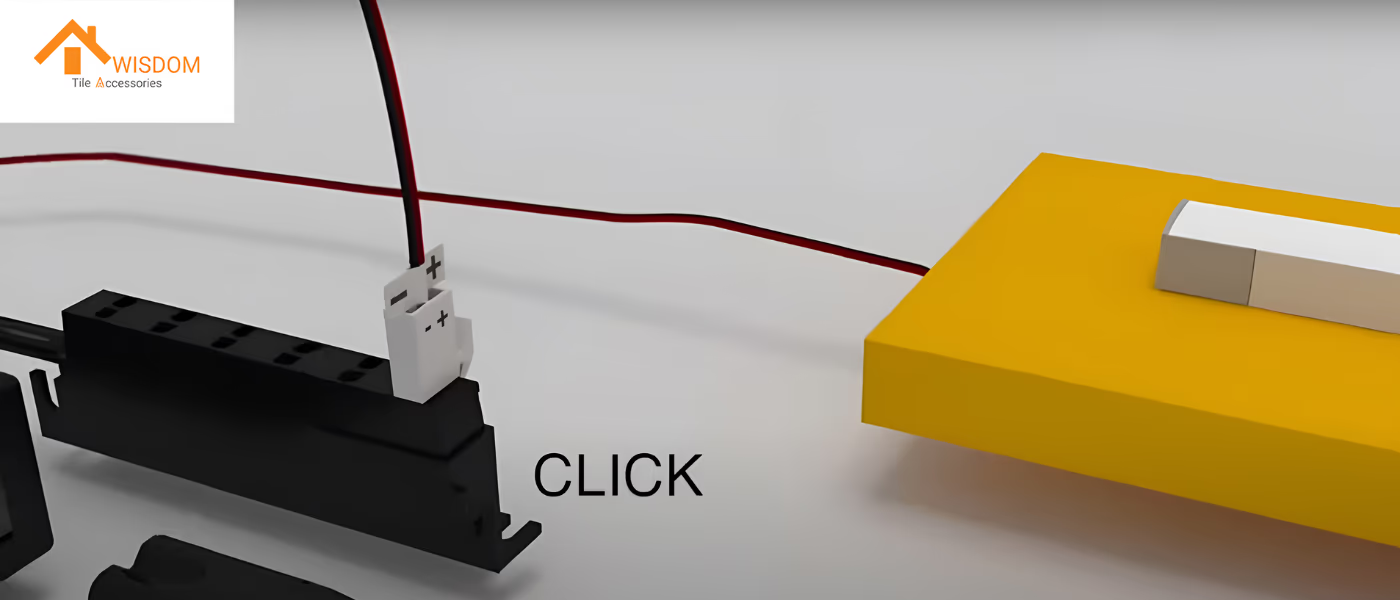

Wiring and Connecting

Connect your LED strip light to a power supply according to manufacturer instructions. Ensure all connections are secure and insulated with electrical tape if necessary.

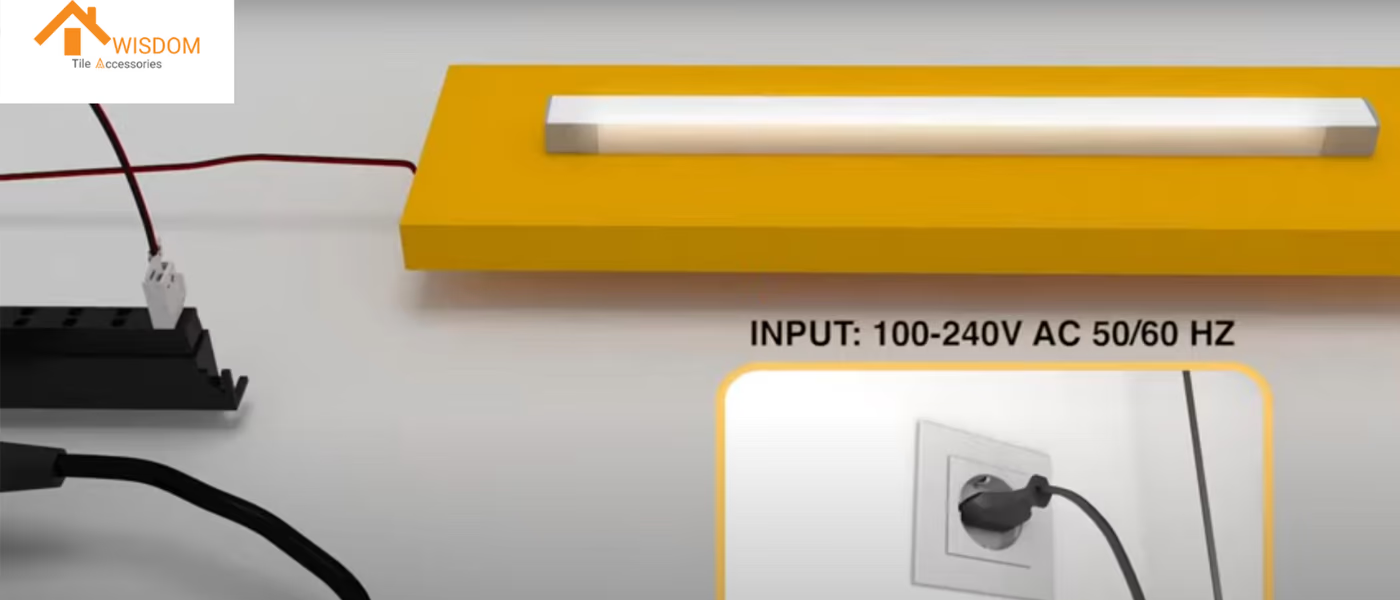

Testing Your Installation

After completing all connections, turn on your LED lights to test functionality. Check for even light distribution along the entire length of the profile.

Adding Diffusers and Finishing Touches

Choosing the Right Diffuser:

Select a diffuser that suits your lighting needs. Options include:

Installing the Diffuser:

To install the diffuser, align it with the aluminum profile. Gently press it into place until it clicks securely. Ensure that it fits snugly to avoid gaps that could affect light diffusion.

Fixed end cap:

After installing the diffuser, install the end caps to both ends of the aluminum profile. Not only do these caps improve aesthetics, they also protect the LED strips from dust and moisture.

Have Questions?

What are the benefits of using aluminum profiles for LED strip lights?

Aluminum profiles provide several advantages, including improved heat dissipation, which extends the lifespan of LED strips. They also enhance the aesthetic appeal of the installation by offering a clean and finished look. Additionally, profiles protect the LED strips from dust and physical damage.

How do I choose the right LED strip lights for my project?

When selecting LED strip lights, consider factors such as brightness (measured in lumens), color temperature (warm or cool light), and length. Ensure that the strips fit well within the chosen aluminum profile and are suitable for your intended application, whether for task lighting or decorative purposes.

What tools and materials do I need for installation?

Essential tools include a measuring tape, hacksaw or cutting tool, wire strippers, and a cleaning cloth. Materials required are LED strip lights, aluminum profiles, diffusers, end caps, mounting clips or screws, and electrical tape. Having everything ready will make the installation process smoother.

What steps should I follow to install LED strip lights in aluminum profiles?

The installation process involves measuring and cutting both the aluminum profile and LED strip to size, attaching the strip to the profile, mounting the profile securely, adding diffusers and end caps, and finally connecting to a power source. Ensure all components are securely installed for optimal performance.

Can I use dimmable LED strips with aluminum profiles?

Yes, you can use dimmable LED strips with aluminum profiles. To achieve this, ensure that your power supply and any controllers used are compatible with dimming functions. This allows you to adjust the brightness of your lighting according to your preferences.