Sharp, clean details often distinguish exceptional construction projects. One such detail is the 'reveal,' a term frequently encountered but sometimes unclear. So, what is reveal in construction? It’s essentially a planned recess or gap between surfaces. Architects and designers utilize reveals intentionally to create visual separation, define edges, manage material transitions, or accommodate slight movement. Understanding this technique is key to appreciating and executing sophisticated building details.

Defining "Reveal" in Construction

What is a Reveal?

In the context of construction and architecture, a reveal refers to the planned, visible gap, recess, or exposed edge intentionally created between adjacent surfaces, materials, or building components. Unlike a flush or butt joint where elements meet directly edge-to-edge, a reveal introduces a deliberate, often linear, space. This space is created by setting one material back from another, by inserting a specific trim piece (like a metal or PVC profile), or by leaving a consistent groove between panels or surfaces. It is a specific detailing technique, distinct from accidental gaps or unfinished joints.

Core Purpose: Why Use Reveals?

The fundamental reasons for incorporating reveals in construction serve a dual role, addressing both aesthetic and practical considerations. Visually, reveals are employed to articulate joints clearly, create crisp shadow lines that add depth, define the separation between different materials or planes, and contribute to a clean, intentional design language. Functionally, they provide a controlled method for handling transitions, accommodating minor variations in materials or installation tolerances, managing expansion and contraction, or concealing unfinished edges. Essentially, reveals offer designers and builders a technique to manage junctions deliberately rather than simply abutting materials.

Types of Construction Reveals

Reveals are not a single entity; they manifest in various forms tailored to specific architectural contexts and functional requirements. To better understand this diversity, reveals can be effectively categorized based on several factors. One primary method of classification is according to their specific location within a building's structure.

Reveals by Location

Wall Reveals

Wall reveals are planned grooves or recesses set into vertical wall surfaces. They are frequently implemented between adjacent wall panels—such as gypsum board, decorative panels, or acoustic units—to create visually distinct lines and effectively manage the joints. Wall reveals also appear at wall corners (internal or external), along transitions between walls and ceilings, or at the junction with the floor (separate from base reveals). These details are common in many modern wall systems, contributing to precise visual edges and a clean overall finish.

Ceiling Reveals

Ceiling reveals are incorporated into ceiling planes. Common locations include the perimeter of a room where the ceiling meets the walls, establishing a clear separation or achieving a "floating ceiling" effect. Reveals are also used within the ceiling field itself to break up large expanses, delineate specific zones, or form features like light coves or coffered designs. They help define the ceiling plane and can integrate elements like indirect lighting or ventilation slots unobtrusively.

Base Reveals (Shadow Lines)

Base reveals, often termed shadow line bases or recessed skirting, occur at the lowest point of a wall where it meets the floor. This method forms a crisp recess instead of a projecting traditional baseboard. The resulting shadow line provides a clean, minimalist transition between wall and floor finishes. This detail is particularly favored in contemporary interiors for its sharp, clean appearance.

Door & Window Reveals

Door and window reveals are formed around the edges of openings within walls, serving as an alternative to conventional casings or architraves. By creating a recess or a defined edge setback around the door or window frame, these reveals achieve a streamlined, integrated look. They sharply outline the opening within the wall surface and provide a controlled transition between the wall finish and the frame material.

Reveal Type | Primary Characteristic / Material Focus | Typical Application / Location |

|---|---|---|

Wall Reveals | Recess or groove on wall surfaces | Between panels, corners, wall junctions |

Ceiling Reveals | Recess or feature within ceiling planes | Perimeters, light coves, field patterns |

Base Reveals (Shadow Line) | Recessed detail at wall/floor junction | Modern alternative to baseboards |

Door/Window Reveals | Recessed edge around openings | Clean frame integration, casing alt. |

Drywall Reveals | Formed using drywall beads/trims | Integrated edges in plasterboard walls |

Metal Reveals | Prefabricated metal profiles (Alum/Steel) | Precise lines, edge protection, panels |

Wood Reveals | Uses timber trims or shaped wood | Wood paneling, cabinetry, natural look |

PVC/Vinyl Reveals | Extruded plastic profiles | Wet areas, cost-effective details |

Reveals by Material

The material chosen to form a reveal significantly influences its final appearance, installation process, and durability. Reveals are commonly created using materials integrated directly into the construction assembly or as distinct trim components.

Drywall Reveals

Drywall reveals are typically formed using specialized drywall beads and trims. These components, often made of metal, vinyl (PVC), or paper-faced metal, are designed to create crisp, recessed edges or channels within gypsum board surfaces. Common profiles include L-beads for edge termination against other materials, J-beads for casing edges, and dedicated reveal beads that form precise grooves. These allow for clean paint lines and defined edges directly within the plasterboard system.

Metal Reveals

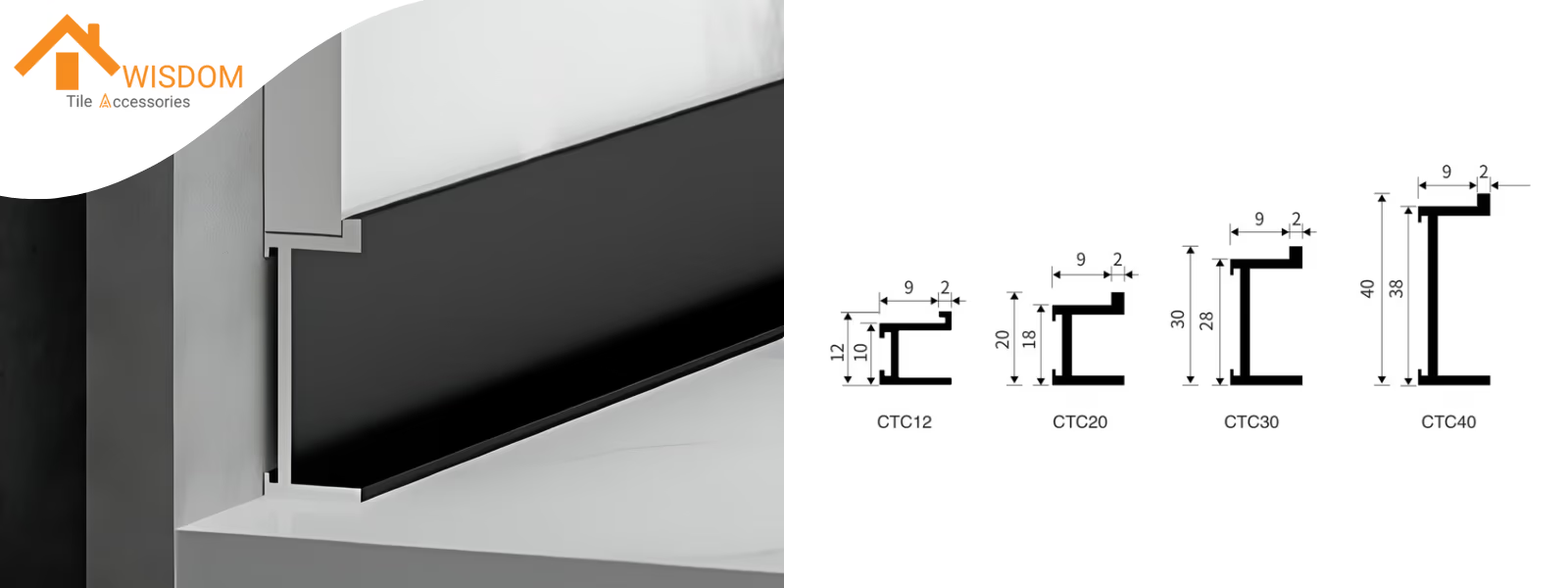

Metal reveals utilize prefabricated profiles, most commonly extruded aluminum or formed steel, to create sharp, consistent reveals. These profiles offer high precision, durability, and clean lines that are difficult to achieve with site-formed methods. Aluminum reveals, in particular, are valued for their corrosion resistance and ability to be finished in various ways (e.g., anodized, powder-coated). Metal reveals are widely used for creating joints between wall panels, at ceiling perimeters, bases, and around openings, providing both edge protection and a refined architectural detail.

Wood Reveals

Wood reveals can be created either by incorporating solid wood trims or by machining grooves and rebates directly into wood panels or structural timber elements. This approach lends warmth and a natural aesthetic to the detail. Wood reveals are often employed in interiors featuring timber cladding, cabinetry, or architectural millwork, allowing for defined joints and transitions consistent with the surrounding wood finishes. The specific wood species and finish significantly impact the final look and durability.

Other Material Reveals

While drywall, metal, and wood are the most common, reveals can also be formed using other materials. PVC or vinyl reveals offer a cost-effective and moisture-resistant alternative, often used in specific applications like bathrooms or exterior soffits. Reveals can occasionally be detailed in composite materials, stone, or even formed directly within cast concrete elements, depending on the specific design requirements and construction techniques employed.

Benefits of Using Reveals

The intentional use of reveals in construction projects offers a range of advantages, extending beyond simple visual preference to include important functional benefits. These collectively contribute to higher quality finishes and more considered architectural outcomes.

Aesthetic Advantages

- Clean Lines & Definition: Reveals introduce crisp, deliberate lines at junctions where materials or planes meet. This visually separates elements, clearly defining edges and contributing to a sense of order and precision in the design. They help articulate the geometry of a space.

- Shadow Effects & Depth: The recess created by a reveal naturally catches light and casts subtle shadows. This interplay of light and shadow adds visual depth and dimension to otherwise flat surfaces, enhancing the architectural character and sophistication.

- Material Separation: When transitioning between different materials (e.g., drywall to wood, tile to plaster), a reveal provides a distinct visual break. This avoids potentially awkward direct abutments and allows each material to terminate cleanly, highlighting their individual textures or colours.

- Modern Look: Reveals are strongly associated with modern and contemporary design aesthetics. Their emphasis on clean lines, minimalism, and precise detailing aligns well with these styles, often replacing more traditional or ornate trims like crown moldings or bulky casings.

Functional Advantages

- Movement Accommodation: Buildings and materials naturally experience minor movements due to thermal expansion, humidity changes, or settling. Appropriately placed reveals can function as control joints, absorbing small amounts of movement without causing visible cracking or stress at the joint.

- Hiding Imperfections: Achieving perfectly flush and aligned joints between different materials or large panels can be challenging and costly. A reveal can effectively mask minor discrepancies in surface alignment or slight variations in material thickness, ensuring a cleaner overall appearance.

- Edge Protection: Reveals created with durable trim materials, particularly metal profiles like aluminum or steel, provide robust protection for vulnerable edges. This is especially beneficial for materials like gypsum board, preventing chipping, cracking, or wear over time, particularly in high-traffic areas.

- Service Integration: Certain reveal profiles are specifically designed to discreetly integrate building services. Common examples include reveals incorporating channels for LED strip lighting (creating seamless ambient or accent lighting) or reveals designed to accommodate linear air diffusers for HVAC systems.

Common Reveal Applications

Reveals are versatile detailing elements found across a wide range of architectural applications. Their use is particularly prevalent where clean lines and precise transitions are desired.

Interior Spaces

Within building interiors, reveals are strategically employed in several key locations:

- Wall-Ceiling Junctions: Reveals are often used at the transition between the top of the wall and the ceiling plane. This creates a distinct separation, sometimes giving the ceiling a "floating" appearance, and avoids the need for traditional crown molding in contemporary designs.

- Wall Bases: As mentioned earlier (Base Reveals/Shadow Lines), creating a reveal at the floor-wall junction serves as a modern alternative to conventional baseboards. This recessed detail provides a sharp, minimalist edge.

- Around Openings: Reveals provide a clean finish around door and window frames. Instead of applying surface-mounted casings, a reveal integrates the frame into the wall plane with a crisp, recessed edge, achieving a more streamlined look.

- Between Wall Panels: Reveals are frequently used to manage the joints between adjacent wall panels. This applies to gypsum board installations, but is especially effective for defining joints between decorative panels, acoustic panels, or different wall cladding materials, ensuring consistent spacing and a high level of finish.

Typical Building Types

While reveals can be incorporated into almost any building type, they are particularly characteristic of certain project categories that emphasize modern aesthetics and refined detailing:

- Commercial & Office Spaces: Corporate interiors often utilize reveals to achieve a sleek, professional, and high-quality appearance in lobbies, corridors, offices, and meeting rooms.

- Hospitality (Hotels, Restaurants): Upscale hotels and modern restaurants frequently employ reveals to contribute to a sophisticated and contemporary guest experience through meticulous detailing.

- High-End Residential: Modern homes, apartments, and luxury residences commonly feature reveals as part of minimalist design schemes, particularly at bases, ceilings, and around openings.

- Institutional Buildings (Museums, Galleries, Universities): Buildings where architectural expression and precise detailing are paramount, such as museums and galleries, often extensively use reveals to enhance spatial definition and finish quality.

How to Choose the Right Reveal for Your Project

Selecting a suitable reveal involves matching design intentions with project conditions and material properties. This section outlines factors influencing the decision process to help achieve the intended outcome.

Define the Primary Objective

Identify the main function the reveal will serve. Is it primarily for visual separation, or does it need to address a technical requirement?

- For visual goals, such as minimalist lines or distinct panel definition, focus on profiles and materials designed to produce that specific appearance.

- For functional requirements, like accommodating movement, managing tolerances, or providing edge protection, select reveal types engineered accordingly. These address specific physical demands of the installation.

Assess Location and Use Conditions

The installation environment affects material durability and performance. Consider the demands of different locations:

- High-traffic areas experience more wear. Materials like robust aluminum profiles or stainless steel offer increased resistance to impact compared to less rigid options.

- Wet or exterior environments require materials resistant to moisture and corrosion. Options include specific aluminum finishes (e.g., architectural grade anodizing/powder coat meeting AAMA 2604/2605), certain stainless steel grades (e.g., 316), PVC/vinyl, or appropriately sealed wood species known for durability.

- Ceiling installations often favor lightweight materials like aluminum or PVC. Integration with services like lighting or air distribution may also influence profile choice.

Examine Material Specifications

Specific material attributes affect performance and lifespan. Referencing detailed specifications aids in proper selection:

- Aluminum: Common specifications cover alloy type (e.g., 6063), profile wall thickness, and the protective finish (e.g., anodizing class, AAMA standard for powder coat). The finish type directly impacts corrosion resistance and appearance retention.

- Steel: Stainless steel provides high durability (specify grade based on exposure). Galvanized steel, used for drywall beads, requires complete paint coverage to prevent potential rusting.

- Drywall Trims: These facilitate painted finishes. The final edge quality depends heavily on the installer's precision. Vinyl provides moisture resistance.

- Wood: Species selection impacts dimensional stability. Thorough sealing, including hidden surfaces and end grains before installation, improves longevity.

- PVC/Vinyl: Offers moisture resistance and can be cost-effective. Check UV ratings for exterior use and compare rigidity to other materials if structure is a factor.

Factor in Installation Requirements

Site conditions and installation methods influence the final appearance of the reveal. Address these practical points:

- Substrate Condition: Reveals follow the substrate line. Plumb, level, and straight substrates allow for correspondingly straight reveal lines. Surface irregularities will be reflected.

- Workmanship: Achieving precise results, such as sharp corners or smooth transitions with certain reveal types, requires careful installation.

- Coordination: Sequencing the reveal installation with adjacent work (drywall, paint, flooring) helps prevent damage and facilitates clean transitions.

Verify Compatibility and Integration

Confirm the selected reveal functions correctly with surrounding components and meets system requirements:

- Dimensional Fit: Profile dimensions (groove width, depth) should match the thickness of the adjacent materials.

- Material Interactions: Avoid direct contact between incompatible metals (which can cause galvanic corrosion) by using separators or selecting compatible materials/finishes.

- Fire-Rated Assemblies: Reveals installed in fire-rated walls or ceilings must utilize products and installation methods specifically tested and approved within a compliant fire-rated system design. Standard reveals typically interrupt the fire barrier.

Conclusion

This article has outlined the definition, types, functions, and application contexts of reveals in construction detailing. Understanding these elements provides a basis for their effective use in building projects.

Summary of Key Aspects

A reveal represents a planned gap or recess between building components, distinct from unintentional joints.

It serves dual purposes: visually defining edges, creating shadow lines, and separating materials, while also accommodating movement, managing tolerances, or protecting edges.

Reveals are implemented in various locations (walls, ceilings, bases, openings) and formed using different materials (drywall trims, metal profiles, wood, etc.), each with specific characteristics.

The Role of Detail in Construction Outcomes

The specification and execution of details like reveals contribute to the final quality and appearance of a built space. Careful attention during design and installation allows these elements to integrate cleanly, manage transitions effectively, and align with the intended architectural character. Well-considered details, consistently applied, reflect the overall standard of craftsmanship and thoroughness within a construction project.

Frequently Asked Questions (FAQ)

Are reveals typically more expensive than standard baseboards or window casings?

Answer: Generally, yes, specifying reveals often involves a higher initial investment compared to standard paint-grade wood or MDF trims. Here's the breakdown:

- Materials: Quality prefabricated reveals, particularly architectural aluminum profiles, usually cost more per linear foot than basic trim options. While simple drywall beads might seem cheap initially, they require more finishing labor.

- Labor: Achieving the crisp, straight lines essential for reveals demands a higher level of precision during installation. This often translates to increased labor time and potentially higher costs, especially if substrate preparation (leveling walls) is needed, which reveals tend to highlight.

- Consider Lifetime Cost: Factor in durability. A robust metal reveal in a commercial space might outlast multiple cycles of repainting or replacing damaged standard trim, potentially offsetting the higher initial cost over the building's lifespan.

Bottom Line: Expect reveals, especially quality metal systems, to have a higher upfront cost. Budget accordingly, considering both material and the necessary installation precision.

Do reveals accumulate dust easily and are they hard to clean?

Answer: Reveals can collect dust, primarily horizontal surfaces like base reveals or ceiling details. However, it's usually manageable:

- Design Matters: Narrow, sharp-edged profiles tend to gather less dust than wider, flatter recesses. Some manufacturers offer profiles with slightly sloped internal edges to minimize settling.

- Location Impact: Vertical reveals accumulate minimal dust. Horizontal reveals are the main consideration. Higher ceiling reveals are harder to reach than base reveals.

- Cleaning Method: Regular cleaning using a narrow vacuum nozzle or a microfiber duster is typically effective. For durable finishes like anodized aluminum or PVC, wiping with a damp cloth works well. Compared to intricate traditional moldings, cleaning simple reveal profiles is often less labor-intensive. Dust accumulation is a factor, but rarely a major maintenance burden if specified appropriately.

Can reveals be used reliably on building exteriors?

Answer: Absolutely, reveals are widely used externally, but success hinges entirely on selecting appropriate materials and ensuring correct installation details to handle weather exposure.

- Material Choice is Key: Prioritize materials designed for exterior conditions. This includes:

- Aluminum: With high-performance finishes like AAMA 2604 or 2605 powder coats, or Class I architectural anodizing (essential for durability).

- Stainless Steel: Grade 316 is recommended for coastal or corrosive environments due to superior corrosion resistance.

- Exterior-Grade PVC/Cellular PVC: Offers good moisture resistance but check UV stability ratings.

- Fiber Cement Reveal Products: Specifically designed for exterior use.

- Durable Woods (Properly Treated): Require rigorous sealing and ongoing maintenance.

- Function & Detailing: Exterior reveals often function as drip edges, manage joints in cladding systems (EIFS, stucco), or provide clean transitions. Meticulous integration with the building's weather barrier, proper flashing, and weep details (if applicable) are critical to prevent water intrusion. Don't treat exterior reveals merely as aesthetic elements; their detailing is part of the weather protection system.

What's the practical difference between a reveal and a control joint?

Answer: While they can look similar or sometimes be combined, their primary purposes differ significantly:

- Reveal: Fundamentally an architectural detail focused on visual separation, creating clean lines, or managing material transitions. Any movement accommodation is often incidental unless specifically designed as such. Tolerances and detailing are typically driven by aesthetics.

- Control Joint (or Movement Joint): An engineered element primarily designed to manage anticipated movement (thermal, shrinkage, seismic) in materials like concrete or large plaster areas. Its location, width, and construction are dictated by structural engineering or material requirements to prevent uncontrolled cracking. Aesthetics are secondary to function.

Key Distinction: Think intent. Reveals are designed for appearance/finishing; control joints are engineered for movement. Using a simple aesthetic reveal where a functional control joint is needed will likely lead to failure.

Is it generally advisable to paint reveal trims on site?

Answer: It depends entirely on the reveal material and its existing finish. Here’s a practical guide:

- Designed for Painting: Drywall beads/trims (metal, vinyl, paper-faced) and unfinished wood reveals are intended to be painted along with the adjacent surface after proper priming. This achieves a monolithic look.

- Paintable with Caution: Some metal reveals supplied with a basic primer can be painted on site. However, achieving durable adhesion requires meticulous surface preparation (cleaning, possibly etching, specialized primers) and careful application. Results often struggle to match the quality and longevity of factory finishes.

- Generally Avoid Painting: High-quality pre-finished metal reveals (anodized, factory powder-coated) and most PVC/vinyl reveals derive their aesthetic and performance from the factory finish. Painting these surfaces is usually not recommended. Adhesion is often poor, the finish is easily damaged, it rarely looks as good as the original, and it can void manufacturer warranties. Select these when you intend for the reveal's own finish to be visible.