A newly installed tile floor appears as a single, monolithic surface, seemingly impervious to change. This perception of rigidity is a common and costly fallacy. In reality, every tile installation is a dynamic system, constantly subjected to invisible forces that cause it to expand, contract, and shift. When this inherent movement is restrained, stress accumulates within the assembly until it finds a point of failure, often resulting in sudden, irreparable damage. Properly engineered expansion joints are not an optional feature; they are a mandatory design element required to manage these forces and preserve the integrity of the installation.

What Is a Tile Expansion Joint?

A tile expansion joint is a planned, flexible gap that extends through the tile and setting material. Its purpose is to absorb movement and relieve stress within the tiled assembly. This distinguishes it from a standard grout line, which is filled with a rigid, cementitious material and offers no capacity for movement.

The function of the joint determines its type:

- Perimeter Joints: These isolate the tile field from restraining surfaces such as walls, columns, and cabinetry, preventing stress transfer from the building structure to the tile.

- Intermediate Joints: Also known as field joints, these divide large expanses of tile into smaller, independent sections, or bays. This manages the cumulative stress generated by the tile's own thermal and moisture-related movement.

- Structural Joints: These are aligned with pre-existing movement joints in the building's substrate. They allow the tile installation to accommodate the larger movements of the structure itself, such as those from slab settlement or construction joints.

>> See What is a Movement Joint? All the Types You Need to Know

The Forces That Destroy Tile Installations

Three primary sources of stress act upon every tile installation. Understanding these physical forces is fundamental to preventing tile failure.

Thermal Expansion and Contraction

All materials expand when heated and contract when cooled. The rate at which this occurs is defined by the material's Coefficient of Thermal Expansion (CTE). In a tile assembly, the tile, mortar, and substrate (such as a concrete slab) each have a different CTE. As ambient temperature changes, these layers expand and contract at dissimilar rates, generating powerful shear stresses at the bond line between them. A floor area exposed to direct sunlight, for instance, can experience significant temperature swings, causing substantial internal movement that, if restrained, builds compressive force within the tile layer.

Moisture Movement and Swelling

Porous materials, including many types of ceramic tile, natural stone, and cementitious setting materials, absorb ambient moisture. This absorption causes the materials to swell in a process known as hydro-expansion. The subsequent drying and shrinking create a continuous cycle of stress. In environments with high humidity or direct water exposure, such as bathrooms, showers, and exterior patios, this cyclical moisture movement can compound thermal stresses and accelerate the degradation of the tile assembly.

Structural Shifts and Substrate Changes

Buildings are not static. They are subject to movement from live loads (occupants, furniture), dead loads (the weight of the structure itself), vibration, and ground settlement. Furthermore, a new concrete slab undergoes significant drying shrinkage for months or even years after it is poured. This shrinkage places the bonded tile layer under immediate and sustained compression. Without joints to isolate the tile from these powerful substrate movements, the forces are transferred directly into the rigid tile field, leading to failure.

What Happens Without Proper Expansion Joints?

Omitting expansion joints guarantees that the cumulative stresses from thermal, moisture, and structural forces will become trapped within the tile assembly. The most dramatic consequence of this oversight is a failure mode known as "tenting."

Tenting occurs when the built-up compressive force within the tile field exceeds the bond strength of the setting mortar. Unable to expand outward due to perimeter restraints, the tiles are forced to buckle upward, lifting off the substrate and forming a distinct tent-like shape. This failure is often sudden and can occur with an audible report, sometimes years after the installation was completed. The delay is significant; it indicates that the initial bond was adequate, but the relentless, cyclical accumulation of stress eventually overwhelmed the system.

Other consequences of omitting movement joints include random cracking of individual tiles, chronic grout disintegration, and the gradual debonding of tiles from the substrate.

Understanding Catastrophic Tenting

Tenting is not a sign of a weak bond but rather a symptom of flawed engineering. Key points to recognize are:

- It is the direct result of unrelieved compressive stress within the tile layer.

- The failure often occurs months or years after the installation, proving that stress accumulation is a long-term process.

- A floor that has experienced widespread tenting is typically unrecoverable and requires complete demolition and replacement.

Where to Place Tile Expansion Joints

The placement of movement joints is not arbitrary. It is governed by prescriptive industry standards, most notably the Tile Council of North America (TCNA) Handbook. Adherence to these guidelines is a requirement for a durable installation.

At the Perimeter of Every Room

A flexible joint is required wherever the tile field abuts a restraining surface. This includes walls, columns, pipes, and the edges of dissimilar flooring materials. This perimeter gap isolates the tile from structural movement and provides the primary space for the field to expand. The preferred minimum width for this joint is 1/4 inch (6.35 mm), and it must be kept completely free of rigid grout or mortar.

Over Existing Joints in the Substrate

This rule is non-negotiable. Any structural, control, or saw-cut joint present in the concrete slab or underlying substrate must be honored. A corresponding movement joint of the same width or wider must be installed in the tile assembly directly above the substrate joint. Tiling over a substrate joint traps the movement below, guaranteeing a crack will telegraph through the tile.

At All Changes of Plane

Flexible joints are required at all inside corners where tiled surfaces meet. This applies to floor-to-wall junctions and wall-to-wall corners. These areas concentrate stress, and a rigid grout joint will invariably crack.

Within Large Tiled Fields

Large tiled surfaces must be subdivided into smaller bays with intermediate movement joints to manage internal stress. The required frequency of these joints depends on the level of environmental exposure.

Condition | Maximum Spacing (In each direction) | Minimum Joint Width |

|---|---|---|

Interior (No direct sunlight or moisture exposure) | 20–25 ft (6–7.6 m) | 1/8 in (3.18 mm) |

Interior (Direct sunlight or moisture exposure) | 8–12 ft (2.4–3.7 m) | 1/4 in (6.35 mm) |

Exterior Applications | 8–12 ft (2.4–3.7 m) | 1/4 in (6.35 mm) |

With Underfloor Heating | 16–20 ft (5–6 m) | 1/4 in (6.35 mm) |

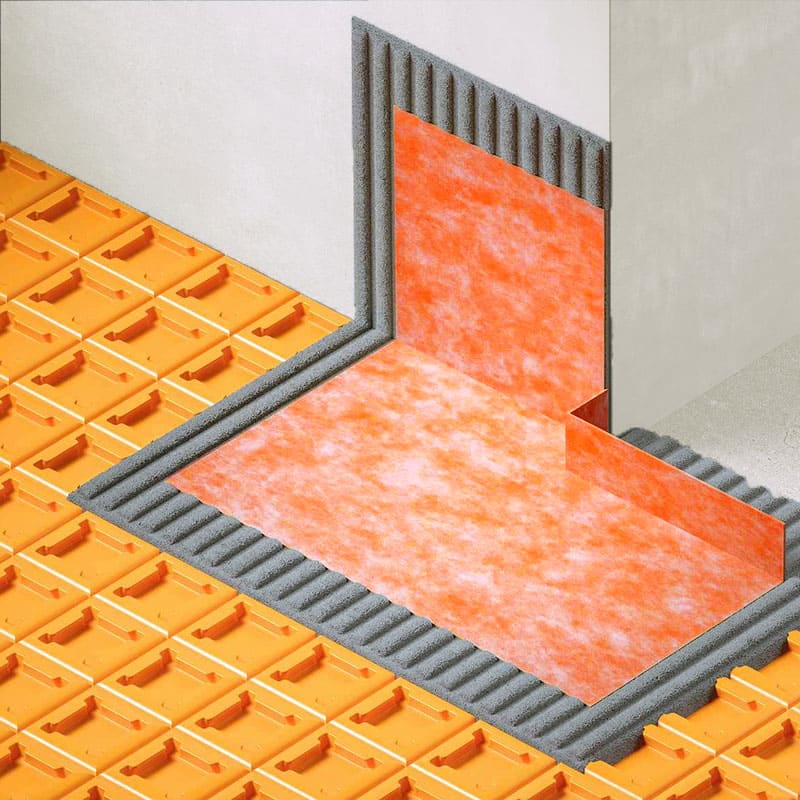

Do Uncoupling Membranes Replace Expansion Joints?

A frequent and critical misunderstanding is that uncoupling membranes eliminate the need for expansion joints. This is incorrect. The two systems perform distinct and complementary functions.

An uncoupling membrane is installed between the substrate and the tile assembly to manage lateral shear stresses. It effectively separates, or "uncouples," the tile layer from the substrate, preventing cracks in the substrate from transferring into the tile and absorbing stress from minor substrate movement.

However, an uncoupling membrane does not accommodate the expansion and contraction of the tile layer itself. The tile field will still expand and contract due to temperature and moisture changes. Without intermediate and perimeter expansion joints, this movement will be restrained, and the compressive forces will build until failure occurs. Therefore, uncoupling membranes and expansion joints must be used together to create a fully protected, resilient tile installation.

Choosing the Right Expansion Joint Solution

A functional movement joint can be created using one of two primary methods: prefabricated profiles or field-applied sealants. The choice depends on the application's demands for performance and appearance.

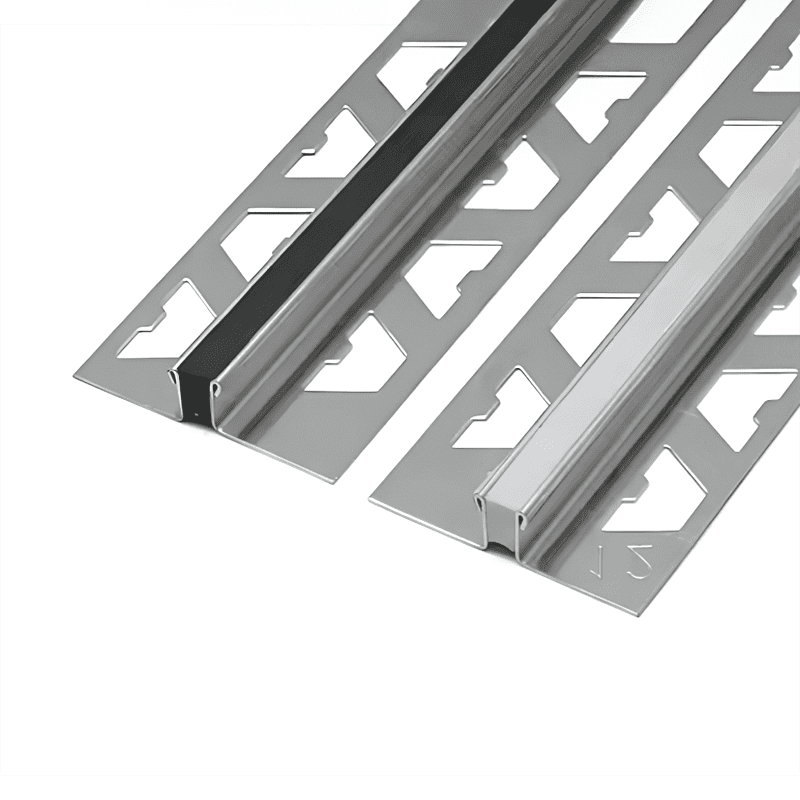

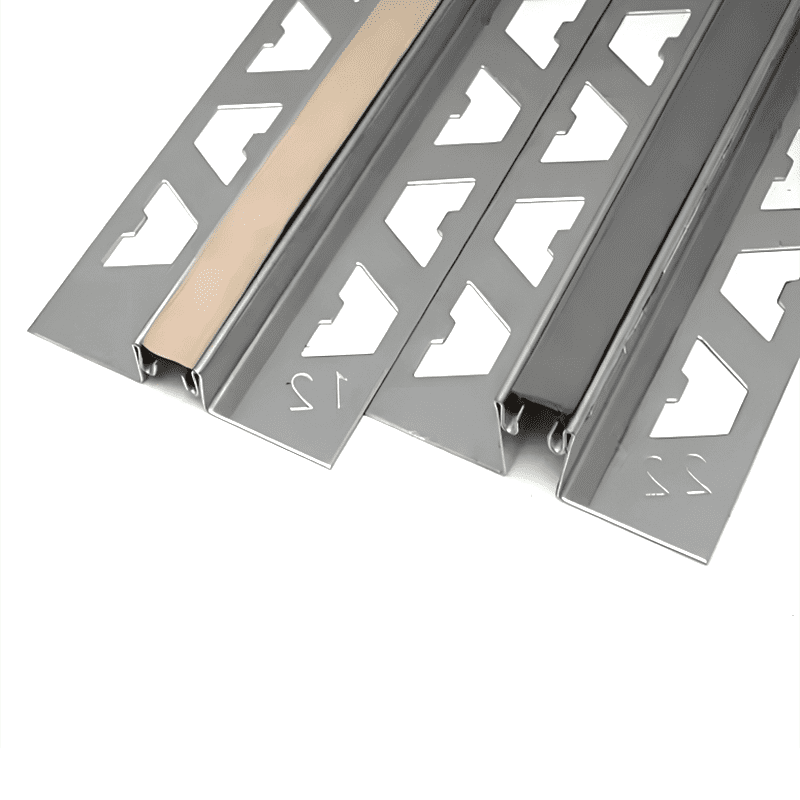

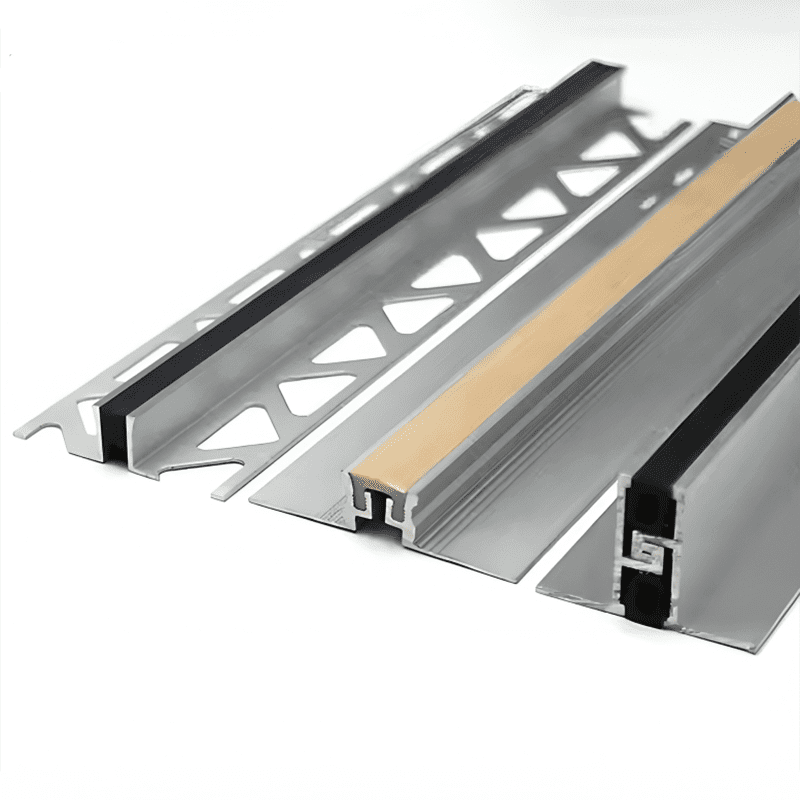

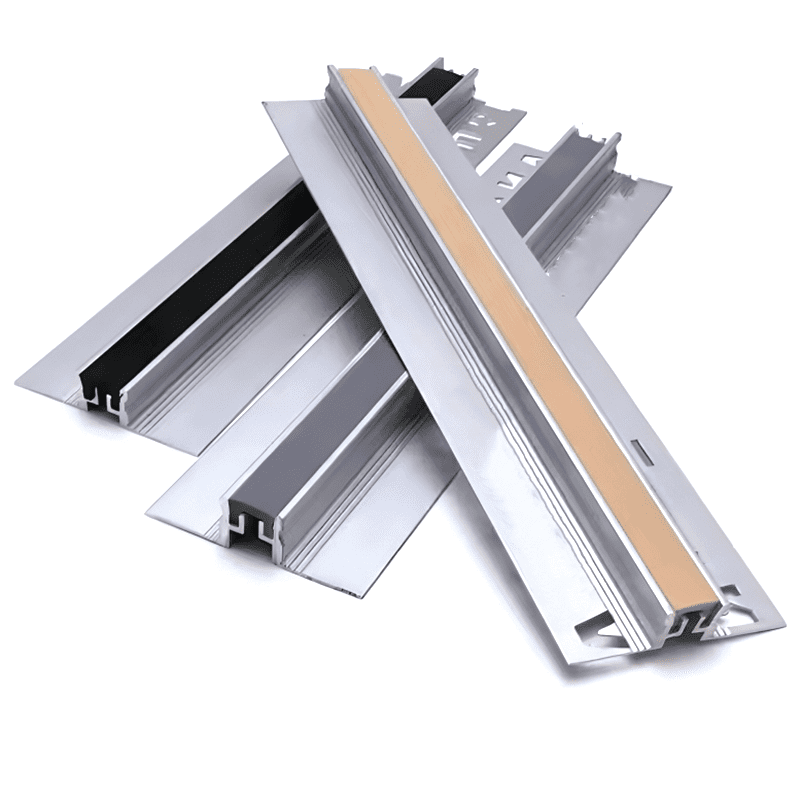

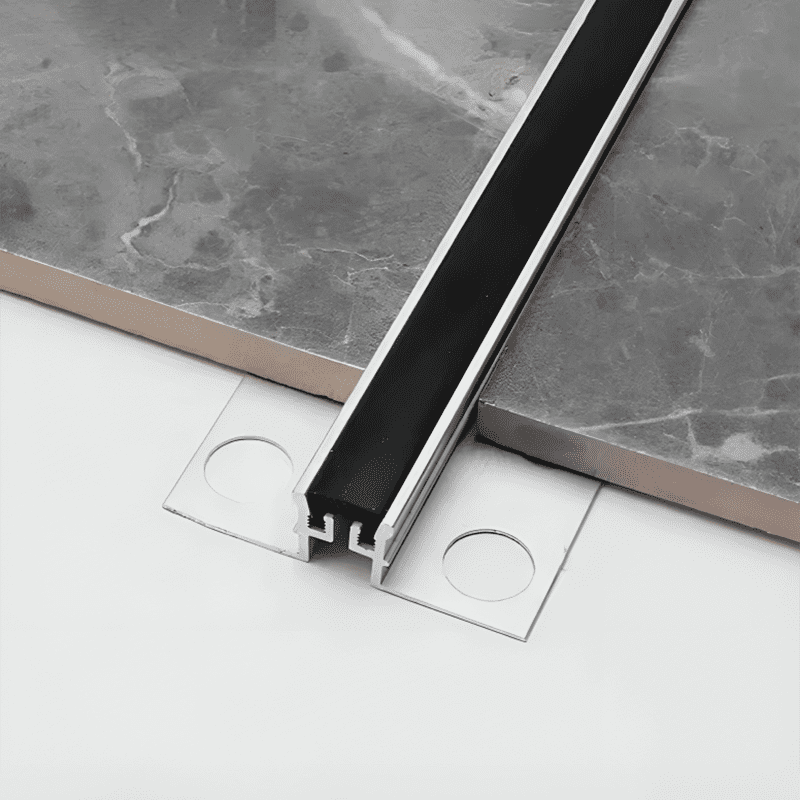

Prefabricated Movement Joint Profiles

These are engineered components that consist of rigid anchoring legs, typically made of metal or PVC, which are embedded in the mortar bed. These legs hold a flexible central insert that absorbs movement. Prefabricated profiles offer superior protection for tile edges against impact damage, making them ideal for high-traffic areas. They also ensure a joint of uniform width and performance. Materials like aluminum and stainless steel offer different levels of load-bearing capacity and corrosion resistance.

Field Applied Sealant Joints

Often called "soft joints," these are created on-site by filling the gap with a flexible sealant. For a sealant joint to function correctly, three components are essential:

- ASTM C920 Compliant Sealant: The joint must be filled with a high-performance elastomeric sealant, such as 100% silicone or urethane. These materials are formulated to withstand repeated cycles of expansion and contraction. Standard caulking is not a substitute.

- Backer Rod: A compressible, closed-cell foam rod must be inserted into the joint before the sealant is applied. The backer rod controls the depth of the sealant and prevents it from bonding to the bottom of thejoint.

- Proper Geometry: The sealant must not bond to the bottom of the joint (a condition known as three-sided adhesion), as this severely restricts its ability to move. The backer rod ensures the sealant only adheres to the two sides of the tiles. The ideal geometry for the sealant bead is a width-to-depth ratio of 2:1, which maximizes its flexibility.

Movement Joint Profile Material Comparison | Aluminum | Stainless Steel |

|---|---|---|

Load Capacity | Moderate. Suited for foot traffic and light commercial use. | Superior. Suited for heavy commercial traffic and industrial loads. |

Corrosion Resistance | Good. Anodized finishes provide protection against oxidation. | Excellent. Inherently resistant to rust and chemical exposure. |

Application Suitability | General interior floors and walls. | Commercial kitchens, exterior areas, wet environments, high-traffic zones. |

Cost | Lower initial cost. | Higher initial investment for long-term performance. |

Frequently Asked Questions

How wide should a tile expansion joint be?

The width depends on its location and purpose. Perimeter joints should be at least 1/4 inch (6.35 mm). Intermediate joints in interior floors are typically 1/8 inch to 1/4 inch (3.18 mm to 6.35 mm). In exterior applications or areas with high thermal movement, joints should be 1/4 inch to 1/2 inch (6.35 mm to 12.7 mm) or wider, as specified by an architect or engineer.

Can I fill an expansion joint with grout?

No. An expansion joint must be filled with a flexible material, such as an ASTM C920 compliant silicone or urethane sealant, or a prefabricated profile with a flexible insert. Filling the joint with rigid cementitious grout negates its purpose, blocks movement, and will lead to failure.

Are expansion joints necessary in small rooms?

Yes. Perimeter expansion joints are required in all rooms, regardless of size. Every tile field must be isolated from restraining walls and other surfaces. While a small room may not require an intermediate field joint, the perimeter joint is mandatory to accommodate movement and prevent stress buildup at the edges.

Do I need more expansion joints with underfloor heating?

Yes. Underfloor heating systems introduce significant and frequent thermal cycles, causing the tile assembly to expand and contract more than an unheated floor. For this reason, industry standards require that the spacing between intermediate expansion joints be reduced, typically to a maximum of 16-20 feet (5-6 meters) in each direction.

What is the difference between an expansion joint and a control joint?

In the context of tiling, an "expansion joint" (or movement joint) is a gap designed to accommodate movement within the tile assembly itself. A "control joint" is typically a saw-cut joint placed in a concrete slab to encourage shrinkage cracking to occur in a straight, predictable line. When tiling over a slab with control joints, you must install an expansion joint in the tile directly over the control joint below.

Can I hide tile expansion joints for a better look?

Perimeter expansion joints are easily hidden beneath skirting boards or baseboards, provided the board is not fixed tightly to the floor. For intermediate joints in the middle of a floor, aesthetic concerns can be addressed by using modern, low-profile prefabricated joints designed to mimic a grout line or by selecting a sealant color that closely matches the grout. Hiding the joint must not compromise its function.