Metal roofing: It’s like the Swiss Army knife of coverings. It’s got a tool for every job, from beating back the sun to laughing in the face of hail. And its popularity? Skyrocketing faster than a cat that’s seen a cucumber.

Section 1: Preparation - Essentials First

Safety First: Before you even glance at a sheet of metal roofing, gear up. Gloves to keep your digits nice and intact, goggles to guard those peepers, and hearing protection because metal cutting is no symphony. Remember, the goal is to end the day with as many body parts as you started with.

Choose the Right Tool: Tin snips, nibblers, metal saws—these are your new best friends. Treat 'em right, keep 'em clean, and they'll slice through metal smoother than a hot knife through butter. Maintenance isn't just a fancy word; it's the difference between a clean cut and a jagged mess.

Know Your Material: Not all metal roofs are playing the same game. Some like to play hard to get, like that burnished slate that's as tough as it is elegant. Copper? It'll shine like a new dime if you cut it right. And dark bronze, that's the diva of the bunch, demanding just the right touch. Know your materials, and you won't get played.

Section 2: Measuring and Marking - Accuracy is Key

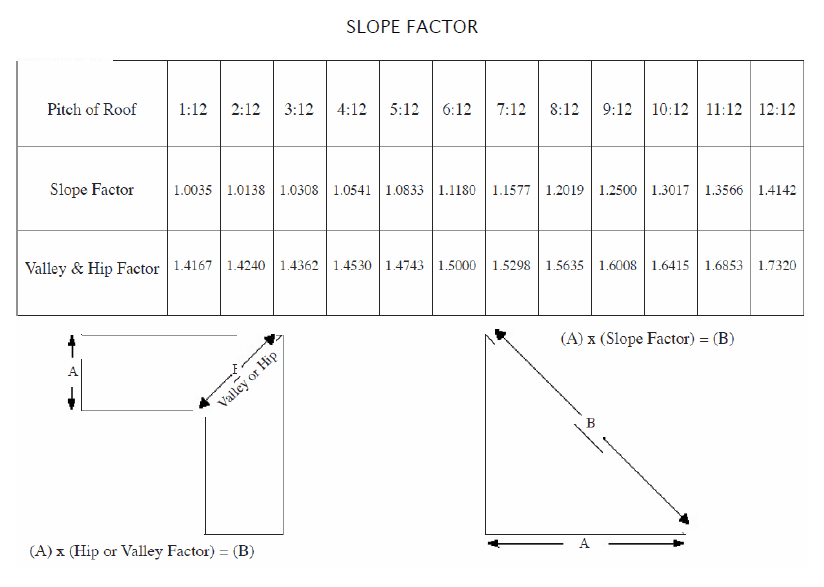

Precise Measuring: You wouldn't eyeball the measurements for a space shuttle; don't do it for your metal roof. Every cut counts. Measure twice, cut once, and always remember the golden rule of roofing: plan for the overlap. This is especially crucial for the high-fashion areas of your roof like ridge caps and valleys, where precision is not just a buzzword but your roof's best buddy.

Clear Marking: Imagine playing tic-tac-toe, but every line you draw is permanent. That's marking metal panels for you. Use a non-slip ruler and a fine-tip marker to draw your cut lines—make them stand out like a polar bear in a snowstorm, even on the snazziest of colored panels. Visibility is your friend and guessing is your foe.

Component Cutting: Now, the ridge caps, gable trim, and valleys are like the crown jewels of your roof. They need to be cut with the grace of a ballroom dancer and the precision of a brain surgeon. No pressure, right? But seriously, each component has its own playbook for cutting. Follow it, and you'll have a roof fit for royalty.

Section 3: Cutting Techniques - Clean and Safe

Straight vs. Corrugated: Straight cuts on metal are as satisfying as slicing through a fresh loaf of bread. But unlike bread, corrugated sheets need a bit more finesse—like navigating a river's current. Respect the waves, and they'll respect your blades. And keep those cuts clean, unless you want your roof to look like it's been chewing on rocks.

Complex Shapes: Now we're getting to the good stuff. Valleys, angles, and ridge caps are the Everest of roofing cuts. They're not just complex; they're what separates the wheat from the chaff. Take your time, double-check your angles, and remember: a good cut here is worth its weight in gold.

Feature Cuts: Got skylights, pipe boots, or gutters? Then you've got yourself a puzzle. Each feature needs a custom cut, like a tailor fitting a suit. There's no one-size-fits-all here; it's more like a "measure-twice-cut-once-and-maybe-sweat-a-little" situation.

Section 4: Post-Cutting - Finishing Up

Smooth Edges: After you've made your cut, you'll find burrs clinging to the edges like unwanted party guests. They're sharp, and they'll snag on anything—a real nightmare. So, grab your deburring tool and give your metal a once-over to make it as smooth as Sinatra. This isn't just about looking pretty; it's about not having a roof that fights back when you're trying to install it.

Panel Storage: Think of your metal panels like a stack of cards. Leave them askew, and they might just warp like a vinyl record on a sunny day. Whether you're stashing them for the night or for the season, keep them flat, keep them dry, and treat them like the precious cargo they are. A warped panel is about as useful as a chocolate fireplace.

Workspace Maintenance: Metal shavings are the glitter of the roofing world—get them once, and you'll be finding them forever. They're also a fast ticket to scratch city on your shiny new panels. So, keep that shop vac handy and treat your workspace like a crime scene—leave no trace, and your future self (and your client's car tires) will thank you.

Section 5: Advanced Cutting - Mastering the Craft

Curved Roofing Cuts: Cutting curves in metal roofing is like teaching an old dog new tricks—challenging but not impossible. Whether you're aiming for a gentle roll or a daring arch, it's all about the right tools and a steady hand. Go slow, follow the line, and remember that in roofing, as in life, the best curves are the ones you plan for.

Profile Precision: Not all metal is flat, and not all cuts are straight. When you're dealing with profiles from ribbed to standing seam, you'll need to be as precise as a Swiss watchmaker. It's like playing Operation—make the wrong move, and you'll be buzzing back to square one. Use the right snips, keep your hands steady, and cut with confidence.

Section 6: Adaptation - Custom Solutions

Mobile Homes and More: So, you're working on a mobile home that moves more than a restless leg? Keep your cuts custom. Mobile homes are like the rogue of the housing world; they play by their own rules. Brick houses, on the other hand, are the stoic warriors—solid and dependable. Each structure demands its own cutting style—adapt and conquer.

Integrating Insulation: Slapping insulation under your metal roof is like giving it a cozy blanket—it's all about the snug fit. But remember, cutting metal with insulation in mind is like playing Tetris. You've got to make everything line up just right, or it's game over. Measure your insulation, mark your metal, and cut with the precision of a tailor to get that perfect fit.

Section 7: Avoid Common Mistakes - Stay Sharp

Measurement Missteps: Ever heard the tale of the roofer who eyeballed his cuts? Yeah, neither have I, because they don't last long. A fraction off here, a millimeter there, and suddenly you're wearing the 'I messed up' hat. Avoid the walk of shame by measuring like your job depends on it—because it does.

Tool Misuse: Grabbing a metal saw when you need tin snips is like bringing a cannon to a knife fight—overkill and a rookie move. Know your tools, love your tools, and use them wisely. It's the difference between a job well done and a 'what on earth happened here?' situation.

Safety Oversights: Last call for safety! Skipping out on your gear is a gamble with worse odds than a rigged slot machine. Don't be the cautionary tale; be the guy who makes it home with all fingers and toes intact, ready to roof another day.

Conclusion

Cutting metal roofing isn't rocket science, but it's close. It’s an art form that balances precision with practical know-how. Remember the key takeaways: measure like a miser, cut with confidence, and always—always—play it safe. Get these right, and you're not just cutting metal; you're crafting shelters.

Take these tips, put them to work, and watch your metal roofing game go from trash to treasure. Now, go forth and cut metal like a maestro, and let the world marvel at the sharp lines and snug fits of your metallic masterpiece.

Related Question About Metal Roofing

Q: How long does a metal roof last?

A metal roof is built to stand the test of time. When properly installed and maintained, you can expect a metal roof to last for 40 to 70 years, or even longer. Its lifespan far surpasses that of traditional roofing materials.

Q: How to install metal roof?

Q: Can you paint metal roofing?

Yes, you can! If you want to change the color of your metal roof or refresh its appearance, it's possible to paint it. Choose high-quality, reflective paint to enhance energy efficiency and extend the roof's lifespan. Proper surface preparation is crucial for a long-lasting finish.

Q: How to install standing seam metal roof?

Q: How to clean metal roof?

Regular cleaning is essential to keep your metal roof looking its best. Use a gentle solution of mild detergent and water, along with a soft brush or cloth, to remove dirt and debris. Avoid harsh chemicals that could damage the finish.

Q: How to fix a leaking metal roof?

If you notice a leak, act promptly to prevent further damage. Identify the source of the leak, remove any damaged sections, and replace them. Seal seams and connections with appropriate sealants. Regular inspections can help catch issues early.

Q: How to install ridge cap on metal roof?

Q: How to keep from sliding on a metal roof?

Safety is paramount when working on a metal roof. Use appropriate safety gear like non-slip shoes and a safety harness. Install safety rails or use walk boards to prevent accidents.