The Architectural Woodwork Institute (AWI) establishes industry standards for millwork in construction, including the critical AWI specs for floor variance. These specifications define the acceptable tolerances for floor levelness and flatness, ensuring that floor irregularities do not compromise the installation of millwork or other structural elements. Adhering to AWI’s floor variance guidelines helps maintain the integrity of both the aesthetic and functional aspects of a building.

For construction teams, understanding and following these specifications minimizes errors, enhances installation precision, and ensures that the final product meets the desired quality standards.

Section 1: Understanding AWI Specs for Floor Variance

What Are AWI Specifications?

AWI specifications are the industry benchmarks that define quality, precision, and reliability in architectural woodworking. They ensure that materials and installations are not only functional but also aesthetically cohesive. From cabinetry to trim, AWI’s guidelines cover everything, ensuring consistency and craftsmanship throughout a project.

When it comes to AWI specs for floor variance, these are particularly important because the floor acts as the foundation for the entire structure. The flatness and levelness of the floor directly influence how millwork and other components align during installation. For instance, a floor with excessive variance can lead to uneven surfaces, which in turn causes misaligned cabinetry, doors, and other millwork installations. AWI sets clear tolerances to prevent these issues, ensuring the surface is ready for precise, high-quality millwork installation.

AWI Floor Variance Specifications

AWI’s floor variance specifications outline the exact allowable limits for floor irregularities, such as the acceptable deviation from levelness over specified distances. For example, AWI allows a maximum deviation of 1/8 inch (3.18 mm) over a 10-foot span, ensuring that floors are stable and flat enough for proper millwork installation. Exceeding these tolerances can lead to complications in the installation process, resulting in gaps, misalignments, or structural issues.

The rationale behind these precise limits is simple: floor variance can undermine the structural integrity of a building and affect the overall visual appeal. By setting these standards, AWI helps contractors and designers identify potential issues early, preventing costly repairs or delays later in the project.

Section 2: How to Measure and Assess Floor Variance

Accurate measurement of floor variance is a key step in ensuring the successful installation of millwork. Floors that deviate from the required level can lead to misalignments, which, in turn, cause issues such as gaps between cabinetry and countertops, or uneven door frames.

To assess floor variance, there are a few reliable tools and methods available:

Laser Levels

Laser levels project a straight beam of light across the floor, which helps measure flatness across larger areas. Set the laser at one end of the room, ensuring it's stable. As the beam extends across the floor, measure the gap between the floor and the beam at regular intervals—typically every 3 feet. If the variance exceeds 1/8 inch over a 10-foot span, the floor will likely require some form of correction. This method is quick and effective for identifying major irregularities.

Digital Floor Scanners

For large spaces or when you need a more detailed map of the floor’s surface, digital floor scanners are an excellent option. These devices create a comprehensive 3D map of the floor, identifying deviations from level at any point on the surface. Simply position the scanner at the starting point of the floor, move it across the surface as instructed by the manufacturer, and analyze the resulting data. This method ensures that even the smallest discrepancies are detected, allowing for more precise corrective measures.

Straightedges and Measuring Tapes

For smaller or more localized areas, a straightedge and measuring tape can be just as effective. Place the straightedge on the floor and check for any gaps. Use the measuring tape to determine the size of these gaps. This method is simple but essential, especially when checking small, irregular sections of the floor.

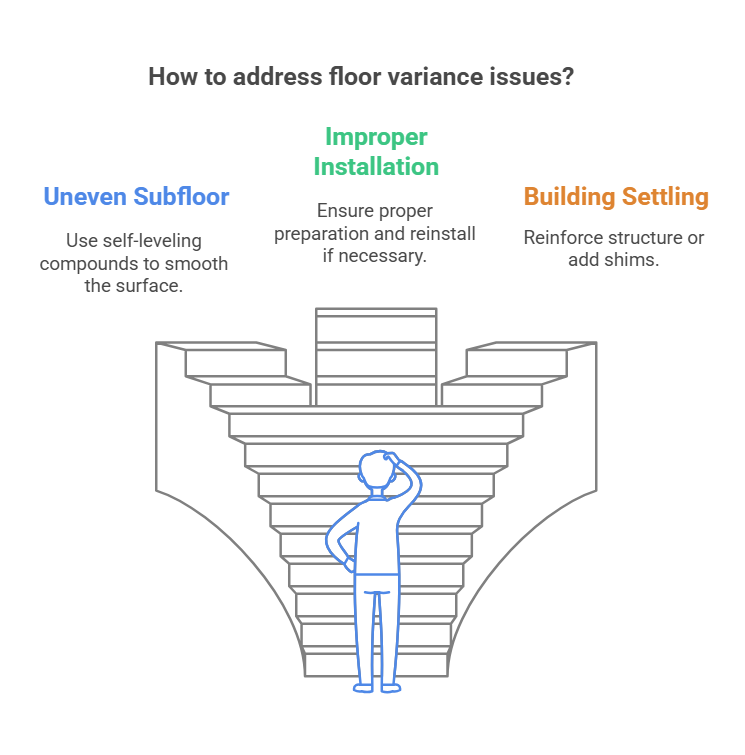

Common Issues and Solutions for Floor Variance

Several issues can arise when assessing floor variance. Here’s how to address the most common challenges:

Uneven Subfloor

Uneven subfloors are often the result of improper installation or settling over time. If the subfloor is not level, it will cause misalignment in the final surface, which can lead to costly installation errors.

Solution: Apply self-leveling compounds to fill low spots and smooth the surface. This ensures that the subfloor meets the necessary flatness standards and provides a solid foundation for flooring.

Improper Installation

In some cases, the issue isn’t with the subfloor but with the way the floor covering is installed. If the floor covering isn’t installed correctly, it can create bumps or misalignments that affect the installation of millwork.

Solution: Ensure that the subfloor is properly prepared before installing any flooring. If the current floor covering was installed incorrectly, it should be removed and replaced.

Building Settling

As buildings age, they naturally settle, causing minor shifts in the floor’s level.

Solution: Reinforce the floor structure or add shims to correct any unevenness caused by settling. In more severe cases, addressing the foundation may be necessary.

Moisture Issues

Excess moisture can cause wood floors to warp or expand, leading to uneven surfaces.

Solution: Control moisture levels throughout construction by using moisture barriers or dehumidifiers. If the floor has already been damaged by moisture, it should be replaced before proceeding with installation.

Section 3: Practical Applications of AWI Specs for Floor Variance

AWI floor variance specifications play a critical role in the successful installation of millwork. By ensuring that the floor is level and stable, these guidelines help prevent issues that can arise during the installation of cabinetry, trim, doors, and windows.

Cabinetry and Countertops

Uneven floors often result in misaligned cabinetry and countertops, which may lead to gaps or visible seams.

Solution: Before installing cabinetry, ensure that the floor is level. If needed, use shims or leveling compounds to correct any discrepancies. This step ensures that the cabinets and countertops are aligned properly and securely.

Doors and Windows

Misaligned floors can cause doors and windows to fit improperly, which can affect their operation.

Solution: Check the floor for levelness before installing doors and windows. Ensuring the floor is level allows these elements to fit properly, improving both functionality and appearance.

Trim and Baseboards

Trim and baseboards can appear misaligned or uneven if the floor is not level.

Solution: Level the floor before installing trim to ensure that everything fits flush against the wall, providing a clean, professional finish.

Ensuring Compliance with AWI Specifications

To ensure compliance with AWI’s floor variance specifications throughout the project, follow these steps:

- Pre-Installation Assessment: Use tools like laser levels and digital scanners to assess the floor’s condition before starting installation. If the variance exceeds the allowable limit, take corrective action before proceeding.

- Ongoing Monitoring: As construction continues, periodically check the floor to ensure it remains within AWI specifications. Be mindful of factors like building settling and moisture that could affect floor levelness.

- Post-Installation Check: After installing millwork, verify that everything is properly aligned. If necessary, make any adjustments to ensure everything fits as it should.

Section 4: Frequently Asked Questions (FAQs)

How can I download the AWI specifications PDF?

To download the latest AWI specifications, visit the AWI website and go to the "Standards" or "Resources" section. The AWI specifications PDF is available for free, and you can access it by registering an account if required. Make sure to download the most up-to-date version to ensure you’re using the current standards. Download AWI Specifications PDF

What is the acceptable range for floor variance according to AWI specs?

AWI specifications provide clear guidelines for floor variance to ensure smooth and precise installation of millwork. The maximum allowable variance is:

- 1/8 inch (3.18 mm) over a 10-foot span for tiles with at least one edge measuring 15 inches (0.38 m) or longer.

- 1/16 inch (1.6 mm) per foot for tiles with all edges shorter than 15 inches (0.38 m).

These limits ensure that the surface is sufficiently flat to allow for proper alignment of components during installation. Exceeding these limits could cause misalignment or structural issues in the final result.

How do AWI floor variance guidelines apply to specific types of construction projects?

AWI’s floor variance guidelines are relevant for all types of construction, from residential to commercial and industrial buildings. They are particularly critical for installations involving cabinetry, flooring, doors, trim, and other millwork, where a flat surface is necessary for precise installation. Adhering to AWI guidelines guarantees consistent results across different building types, preventing issues such as misalignment, structural problems, or visible gaps.

Can I use AWI floor variance guidelines for non-wood floors?

Yes, AWI guidelines apply to all types of floors, whether they are wood, concrete, or tile. The principles of floor variance are the same—ensuring the floor is level and flat enough for millwork installation, regardless of the material. However, the methods used to assess and correct floor variance may differ depending on the type of flooring, so be sure to select the appropriate tools and techniques for the material you’re working with.

Why is it necessary to measure floor variance before starting installation?

Measuring floor variance before installation is crucial to prevent issues during the construction process. An uneven floor can cause misaligned cabinets, doors, trim, and other elements, leading to costly repairs and delays. AWI specifications help identify floor irregularities early, ensuring that any necessary corrections are made before installation begins. This step saves time and money in the long run and ensures a high-quality final result.

How do I fix an uneven floor to meet AWI specifications?

If your floor does not meet the AWI specifications for flatness, you can use a variety of tools and methods to correct it:

- Self-Leveling Compounds: These are ideal for smoothing out low spots on the floor and providing a flat surface.

- Shims: In some cases, you may need to use shims to lift areas that are too low to meet the necessary level.

- Floor Grinding or Sanding: For concrete floors, grinding may be necessary to level out uneven spots.

It’s important to carefully follow the manufacturer's instructions for any materials you use to ensure the floor is brought into compliance with AWI’s guidelines before proceeding with installation.

How often should I check floor variance during a construction project?

It’s essential to periodically check floor variance throughout the construction process. Factors like settling or moisture changes can affect floor levelness. Regular assessments ensure that any changes are identified and corrected before they cause significant issues. Use tools such as laser levels or digital scanners to perform these checks at different stages of the project.

Conclusion

Following AWI’s floor variance specifications is not just a technical requirement—it’s a crucial part of achieving a successful, durable, and aesthetically pleasing construction project. Proper floor preparation ensures that millwork, cabinetry, flooring, and other components are installed correctly, reducing the risk of misalignment, gaps, or other issues that can compromise the quality of the final product.

By sticking to AWI’s guidelines, you’re ensuring that every element of your installation will fit together seamlessly, providing both structural integrity and visual appeal. Whether you’re working on a small residential project or a large commercial building, the importance of proper floor variance cannot be overstated. It’s the foundation of a successful build.