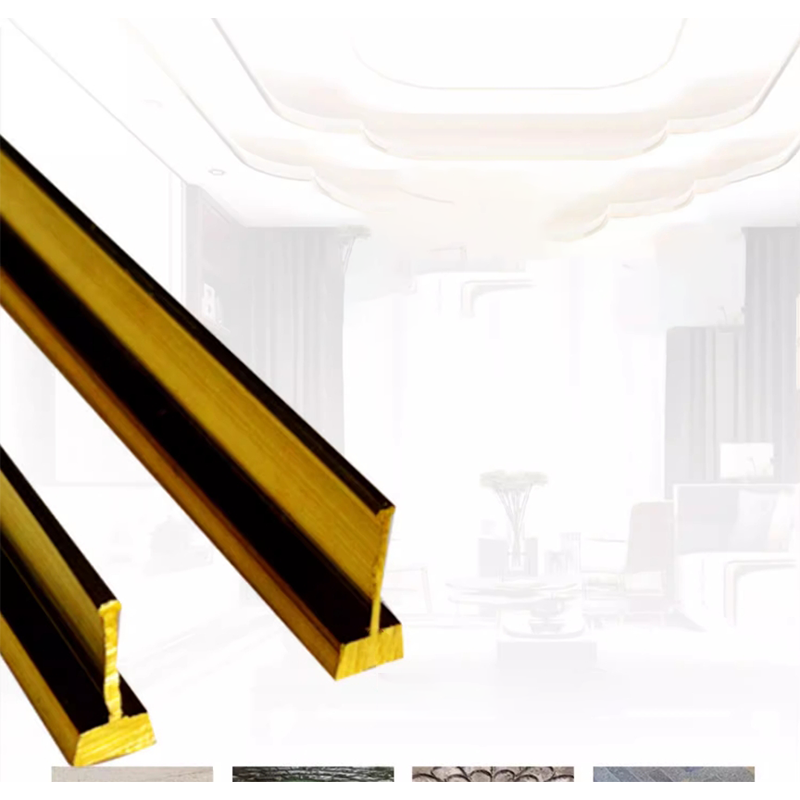

Navigating the intricate world of brass strip manufacturing, our reputation as a leading brass strip supplier in the Philippines is underpinned by an unwavering commitment to quality. In an industry where precision and reliability are paramount, we distinguish ourselves by adopting an ethos of excellence in every facet of our operation.

From the meticulous selection of raw materials to the deployment of advanced manufacturing processes, our approach is holistic. This article delves into the core principles that define our practice, ensuring that the brass strips we supply not only meet but exceed the expectations of our discerning clientele.

How do We Guarantee the Quality of Our Brass Strips?

At the heart of our commitment to excellence is the unparalleled quality of our brass strips. This assurance stems from a foundational approach that integrates stringent quality controls at every stage of production. Here’s a snapshot of our dedicated process:

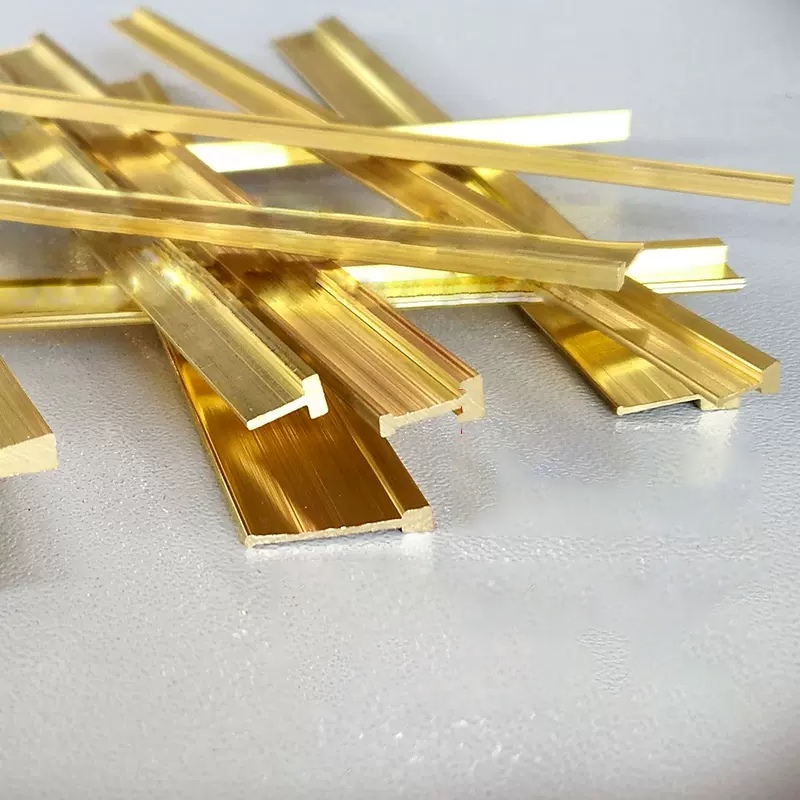

- Stringent Material Selection: Our journey to quality starts with choosing only the highest-grade copper and zinc, ensuring that the foundational materials of our brass strips are of the utmost purity and quality.

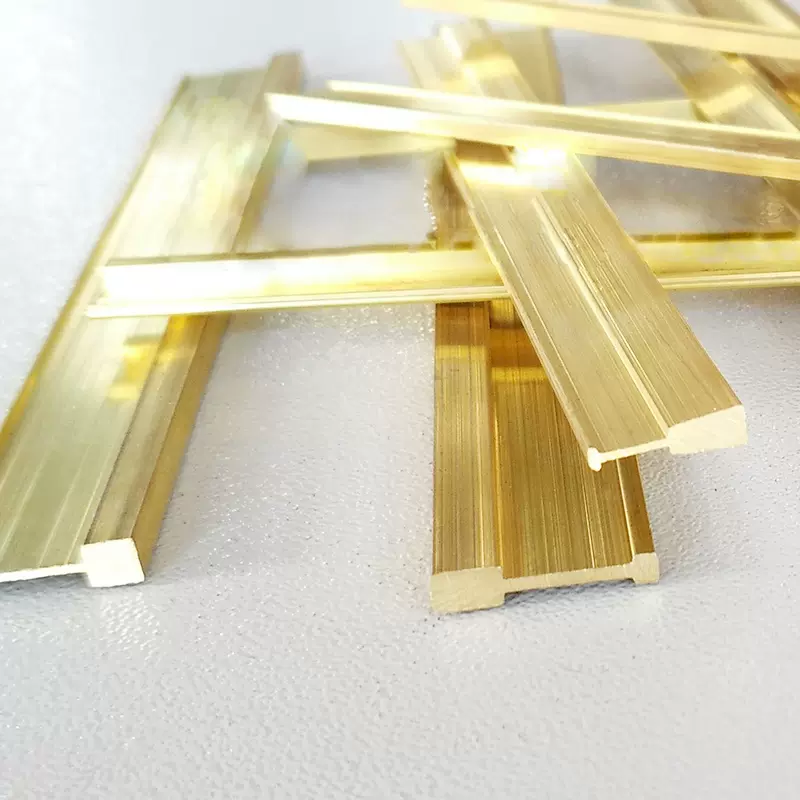

- Advanced Manufacturing Techniques: We employ the latest in manufacturing technology to precisely control every aspect of production. This ensures that each brass strip meets our exacting standards for thickness, width, and overall integrity.

- Dedicated Quality Assurance: Beyond manufacturing, every batch of brass strips undergoes rigorous testing and inspection. Our quality assurance processes are designed to identify and rectify any deviations from our high standards, ensuring consistent excellence.

- Compliance with Standards: We adhere to strict industry standards and regulations in Philippines, ensuring that our brass strips are not only of high quality but also meet all necessary compliance requirements.

Our commitment to quality is unwavering. By meticulously controlling each stage of the process, we guarantee brass strips that stand the test of time, enhancing the value and integrity of your projects.

Why the Brass Strips We Provide are Affordable?

Our commitment to providing affordable brass strips without compromising on quality is a cornerstone of our value proposition. Here’s how we manage to keep our prices competitive:

- Efficient Sourcing and Bulk Purchasing: By strategically sourcing our raw materials and buying in bulk, we leverage economies of scale. This approach allows us to negotiate better prices for high-quality copper and zinc, savings we pass directly to our customers.

- Streamlined Production Processes: Our investment in advanced manufacturing technologies not only ensures the quality of our brass strips but also increases our production efficiency. By minimizing waste and optimizing production time, we keep our manufacturing costs down.

- Long-term Supplier Relationships: We’ve built strong, enduring relationships with our suppliers over the years. These relationships enable us to secure the best prices for raw materials, thanks to our loyalty and consistent order volumes.

- In-House Expertise: Our team’s deep knowledge and expertise in metal processing allow us to make smart decisions that save time and money. This in-house efficiency translates to cost savings for our customers.

- Direct-to-Customer Sales Model: By selling directly to our customers and eliminating middlemen, we reduce additional mark-ups. This direct sales approach ensures that our customers receive the best possible prices.

By focusing on these key areas, we’re able to offer our brass strips at prices that are both competitive and transparent. We believe in delivering value to our customers, ensuring you have access to affordable, high-quality brass strips for your projects.

How do We Ensure Brass Strips are Delivered on Schedule?

Timely delivery is crucial for the success of your projects, and at our core, we understand the importance of reliability. Ensuring our brass strips are delivered on schedule involves several key strategies:

- Robust Inventory Management: Our sophisticated inventory management system plays a pivotal role. By maintaining optimal levels of stock, we're prepared to fulfill orders promptly, minimizing wait times.

- Efficient Production Planning: We closely align our production schedules with forecasted demand and confirmed orders. This proactive planning helps us ensure that we’re always ready to meet our delivery commitments without delay.

- Reliable Logistics Partnerships: We have established strong relationships with trusted logistics and transportation companies. These partnerships enable us to offer flexible and reliable shipping options, ensuring that your brass strips arrive when expected.

- Advanced Order Tracking: Once your order is on its way, we provide advanced tracking capabilities. This allows you to monitor the progress of your shipment in real-time, giving you peace of mind and the ability to plan accordingly.

- Responsive Customer Service: In the event of any unforeseen delays or issues, our dedicated customer service team is on standby to provide updates, answer questions, and resolve any concerns promptly. We believe in clear and open communication with our customers at every step.

By integrating these strategies into our operational framework, we ensure that each order of brass strips is delivered on schedule, supporting the timely and successful completion of your projects.

Can We Supply Brass Strips for Smaller Projects in Philippines?

Absolutely! We recognize the diverse needs of our Philippine customers, including those working on smaller projects or requiring brass strips in limited quantities. Our commitment to supporting projects of all sizes is reflected in our flexible supply capabilities:

- No Minimum Order Requirement: To accommodate smaller projects, we’ve eliminated minimum order requirements for many of our brass strip products. This means you can order exactly what you need, without the worry of excess materials and overspending.

- Custom Cut-to-Size Services: Our custom cut-to-size services are designed to meet the precise needs of your project, no matter the scale. By providing brass strips cut to your specific dimensions, we ensure you receive materials that are ready for use, minimizing waste and saving time.

- Efficient Packaging and Shipping: We understand that smaller projects still require fast and efficient delivery. Our packaging and shipping processes are optimized to handle orders of any size, ensuring that even the smallest quantities arrive safely and on time.

- Personalized Customer Support: Our team is here to assist you with your unique requirements. Whether you're working on a small-scale project or just starting out, we provide the same level of personalized support and advice to ensure your success.

At our company, every project matters. We’re dedicated to providing the flexibility and support needed to supply brass strips for smaller projects, ensuring that all our clients have access to high-quality materials, regardless of the project size.

How do We Tailor Brass Strips to Meet Specific Project Needs?

Customization is key in our industry, and we excel in tailoring our brass strips to meet the specific needs of your projects. Here’s how we ensure our products align perfectly with your requirements:

- Comprehensive Consultation Process: Before we begin any customization, our team conducts a thorough consultation to understand your project's unique needs. This includes discussing specifications, applications, and any particular challenges you might be facing.

- Custom Fabrication Services: Leveraging our advanced manufacturing capabilities, we offer custom fabrication services for brass strips. Whether you need specific widths, thicknesses, or shapes, our precision machinery and skilled technicians can achieve the exact specifications required for your project.

- Specialized Alloys and Finishes: Understanding that different projects may require unique material properties or aesthetics, we provide brass strips in a variety of alloys and finishes. This versatility ensures you get the material best suited to your project’s functional and visual requirements.

- Rapid Prototyping: For projects that are in the development phase, we offer rapid prototyping services. This allows you to test and refine your designs with our brass strips before moving to full-scale production, ensuring the final product is exactly as needed.

- Quality Assurance for Custom Orders: Custom orders undergo rigorous quality assurance testing to ensure they meet your specifications and our quality standards. This includes dimensional checks, material composition analysis, and performance testing as needed.

- Expert Support and Guidance: Throughout the customization process, our experts are available to provide guidance, answer questions, and offer solutions. Our goal is to make sure your custom brass strips not only meet but exceed your expectations.

By focusing on these key areas, we’re able to tailor our brass strips to meet the specific needs of your projects, ensuring that you receive materials that are not just fit for purpose but perfectly suited to your unique requirements.

What Support do We Offer for Our Products?

Our commitment to you extends far beyond the sale of our brass strips. We believe in providing comprehensive support for our products, ensuring you have the assistance and resources you need for successful application and ongoing use. Here’s an overview of the support services we offer:

- Technical Assistance: Our team of experts is available to provide technical support, from selecting the right brass strip for your project to troubleshooting issues during application. Whether you have questions about material properties, fabrication techniques, or compatibility, we’re here to help.

- Customization Guidance: For clients requiring customized brass strips, we offer detailed guidance throughout the customization process. This includes assistance in design, specification development, and selection of the appropriate materials and finishes to meet your project’s specific needs.

- After-Sales Service: We stand behind the quality of our products. Our after-sales service includes handling any concerns or questions you might have post-purchase. Whether it’s a query about your order or additional advice on product application, our team is ready to assist.

- Educational Resources: We provide a wealth of educational resources, including technical datasheets, installation guides, and care instructions. These resources are designed to help you understand and maximize the use of our brass strips in your projects.

- Quality Assurance: Every product we supply is backed by our commitment to quality. Should there be any issues with the quality or performance of our brass strips, our quality assurance team will work with you to resolve the issue promptly, including replacements or adjustments as necessary.

- Responsive Customer Service: At the heart of our support is our customer service team. Responsive, knowledgeable, and friendly, they’re your first point of contact for any needs that arise, ensuring you receive the timely and effective support you deserve.

At Awisdom, our support for our products is a reflection of our dedication to your success. We’re here to ensure that every experience you have with our brass strips is positive, from initial inquiry to long-term application.

How do We Make Sure Our Brass Profiles Meet All Regulations?

Ensuring our brass profiles comply with all relevant regulations is a critical part of our commitment to quality and safety. Here's how we maintain compliance and provide you with products you can trust:

- Up-to-Date Knowledge on Regulations: Our team stays informed about the latest industry standards and regulatory requirements, both locally and internationally. This ongoing education ensures we’re always ahead of compliance issues.

- Certification and Standards Compliance: We adhere strictly to recognized standards and hold relevant certifications for our brass profiles. This compliance is not just about meeting minimum requirements; it's about exceeding them to provide superior quality and safety.

- Rigorous Testing Procedures: Our brass profiles undergo rigorous testing to ensure they meet the necessary regulatory requirements. This includes composition analysis, mechanical property testing, and environmental impact assessments. These tests are conducted in-house and, when necessary, by independent third-party laboratories for unbiased verification.

- Quality Control Systems: We implement comprehensive quality control systems throughout the manufacturing process. From raw material selection to final inspection, every step is designed to ensure compliance with regulatory standards. These systems are regularly audited and updated to reflect the best practices and new regulatory demands.

- Documentation and Traceability: For every batch of brass profiles we produce, we maintain detailed records that provide full traceability. This documentation includes material certificates, test results, and compliance certifications, ensuring that we can quickly provide proof of compliance for our products.

- Collaboration with Regulatory Bodies: We proactively collaborate with regulatory bodies and industry associations to stay ahead of changes in legislation and standards. This collaboration helps us anticipate and adapt to new requirements, ensuring uninterrupted compliance.

- Customer Education: We believe in empowering our customers with knowledge. As part of our commitment, we provide guidance and information on regulatory compliance related to our brass profiles, helping you make informed decisions for your projects.

At Awisdom, we understand the importance of compliance not just for legal adherence but for the safety, reliability, and success of your projects. By implementing these measures, we ensure that our brass profiles meet all regulations, giving you peace of mind and confidence in using our products.

FAQ about Brass Strip Supplier Philippines

How does stringent material selection ensure the quality of brass strips?

Stringent material selection is foundational to the quality of brass strips. By choosing only the highest-grade copper and zinc, we ensure the purity and integrity of the foundational materials. This meticulous approach to material sourcing is crucial because it directly impacts the durability, conductivity, and overall performance of the brass strips. High-quality raw materials lead to superior end products, satisfying our commitment to excellence and meeting the stringent demands of various applications.

What advanced manufacturing techniques are used for brass strip production?

In brass strip production, we employ cutting-edge manufacturing technologies that allow for precise control over every aspect of the production process. This includes the use of automated rolling mills for consistent thickness and width, advanced annealing processes to enhance material properties, and precise cutting techniques for exact dimensions. These sophisticated methods ensure that each brass strip meets our exacting standards for quality and integrity, thereby ensuring reliability and performance in their applications.

How do dedicated quality assurance processes improve brass strip integrity?

Our dedicated quality assurance processes involve rigorous testing and inspection at every stage of production. This includes compositional analysis, mechanical property testing, and dimensional accuracy checks. By identifying and rectifying any deviations from our high standards, we ensure that each batch of brass strips exhibits consistent excellence. These thorough quality checks are pivotal in maintaining the integrity and reliability of our brass strips, reinforcing our unwavering commitment to quality.

Why is compliance with industry standards important for brass strips?

Compliance with industry standards is crucial for brass strips as it ensures they meet established benchmarks for safety, performance, and environmental impact. Adhering to these standards demonstrates our commitment to quality and reliability, fostering trust among our clients. It also ensures that our brass strips are suitable for a wide range of applications, from electrical components to architectural elements, thereby broadening their utility and appeal in the market.

How does efficient sourcing contribute to the affordability of brass strips?

Efficient sourcing and bulk purchasing play a significant role in the affordability of brass strips. By strategically sourcing our raw materials and leveraging economies of scale, we can negotiate better prices without compromising quality. These cost savings are directly passed on to our customers, making our brass strips not only high in quality but also accessible in price. This approach underscores our commitment to delivering value, ensuring that our customers have access to affordable, yet premium, brass strip solutions for their projects.