With the development of real estate industry, more and more properties are being delivered with finishes. The quality requirements of the homeowners for the delivery process of the finely decorated properties are also increasing with the development of the times. In the management of the finishing construction process, wet work plays a more important role in the quality of the whole finishing project.

The occurrence of a large number of tile drums and shedding problems has a greater impact on the average rate of delivery problems and delivery satisfaction of real estate development enterprises, and also has a great potential risk to the safety of residents. In the process of mass finishing residential mass to the market, how to do a good job in the control of mass finishing tile drum rate has a more profound significance.

1 The causes of tile bulging or hollow tiles

1.1 Base layer bulging

(1) Insufficient strength of the grass-roots plaster due to the civil construction process mortar ratio control is not in place, resulting in insufficient strength of the finished plaster surface after the tile paste due to the high strength of the adhesive, resulting in the plaster layer hollow drums.

(2) During the plastering construction process, water was added randomly, mortar was stacked on the ground without mat board, mortar was not used within the specified time to complete, and secondary water was added and mixed for use.

(3) Maintenance is not in place after the completion of plastering, the late inspection of drums is not in place, and the wall tile construction is organized directly without completely solving the problem of wall drums before the construction of a large area of wall tiles.

(4) In the ground flooring pouring process, the concrete slump is too large and not in place after the completion of pouring maintenance, resulting in ground leveling drums and floor tile construction before being completely repaired in place, which began the construction of a large area of floor tile.

(5) kitchen and bathroom waterproofing construction due to the waterproof layer being oily and the formation of drums between the waterproof layer and tiles.

1.2 Interface not cleaned

(1) After the civil construction work surface was transferred to the finishing unit, the finishing unit did not treat the original civil construction plaster surface. to form an isolation layer caused by hollow tiles.

(2) tiles on the wall before use without soaking, because the tile surface residual dust forms an isolation layer and the tiles are too dry, absorbing more moisture from the mastic, resulting in a decline in the adhesive performance of the mastic.

1.3 Mastic, tile adhesive, improper use

(1) unqualified raw materials of mastic, in which the process of material acceptance is not in place, or send inspection mastic and field use of mastic inconsistent with the situation of the second best.

(2) mastic in the mixing process of pollution, or mastic mixed with cement, sand, and other mixed materials. Not according to the different materials of tiles, using the appropriate grade of mastic. Or add too much water to the mixing process of the mastic, resulting in the overall adhesive performance of the mastic decreasing. Due to raw material problems caused by the tile drum off, no matter how much we improve the construction process later or use grouting and other compensatory measures, we cannot solve the completed project tile drum problem; it can only be reworked.

(3) In tile adhesive, add cement. Tile adhesive is made of inorganic materials and polymer additives with a reasonable formula and stable production to protect the performance of tile adhesive. Add cement to change the proportion of the composition of tile adhesive, and the proportion of cement shrinkage is larger and more likely to lead to hollow tiles.

1.4 Construction is not standardized.

(1) The construction process is not full of slurry construction, not using tooth plate scraping, the tile paving process pressure is not in place, and local mastic is not kneaded and squeezed into place.

(2) For the convenience of construction tile batch soaking, in the construction process, there is excessive tile soaking that has not dried on the wall or tile soaking that is insufficient on the wall, which leads to the emergence of a large area of hollow drum problems.

(3) Paving process mastic that is too thick and not used up within the specified time; the second addition of water to the mastic mixing situation, resulting in a quality of mastic that does not meet the requirements, are causes of tile bulging.

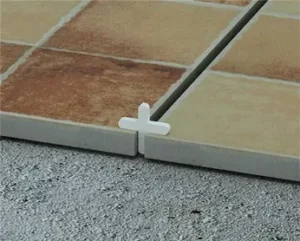

(4) Because the construction process did not use the cross-tile-spacer, tile internal stress could not be released, resulting in the formation of hollow tiles.

2 Common solutions

(1) The material selection process gives priority to tiles with low water absorption, minimizes the use of cement mortar bonding, gives priority to the use of special adhesive construction, and has a two-component backing.

(2) strengthen the work surface handover inspection of the civil foundation for tile paste parts of the mortar using higher strength cement mortar or anti-cracking plaster mortar and do brushing treatment on the surface. For the plaster surface with lower surface strength, in the process of handing over the base surface, pre-reinforced treatment (such as painting wall solid coating and other measures) should be applied. If the reinforced treatment still cannot meet the requirements of tile paste, it needs to be reworked. Strictly control the tile soaking time and drying time, do strict control on the material processing and process in the construction process, and do all the handing over in advance.

(3) the use of professional construction tools, on-site construction of a large area before the completion of the prototype lead system, where each process will be displayed for the new construction workers in the field for the prototype process handover. Strictly control the flow of the overall process and clarify the standards and process of internal handover for each process.

(4) After the construction has been completed, it has been found that at the local corners of the hollow tiles, you can open a local tile with dilute cement paste, and in the process of filling, gently knock with a rubber hammer constantly so that the cement paste gets into the hollow drum parts. If the drum part is in the middle of the tile wall, you can use a special tile drilling bit to open a hole in the uppermost part of the drum. The tile will be gently pried open, not violently smashed, to avoid causing damage to other tile drums. After the removal of a tile, fill in the drum area with thin cement paste, and finally repair the removal of tiles. If the entire wall or floor appears to cover more than 1/3 of the large area of the drum, it is necessary to remove the entire wall or floor and re-pave.

3 Research on backing adhesive

3.1 One-component adhesive backing and two-component adhesive backing

In a comparison of common single-component backing and two-component backing on the market, two-component backing for the liquid plus powder mixed to complete the painting in the back of the tile has a clear sense of grain and burr. One-component backing adhesive after painting the back of the tile into a transparent state, no powder characteristics. So the use of two-component backing can better reduce the probability of tile drums.

3.2 Backing Construction Attention Items

The backing must be fully coated, thickness > 1 mm. Before painting the backing, you need to clean the back of the tile with dust; the surface cannot have bright water. Backing brush thickness is not enough or too thick, and tile dust cleaning is not in place, which will increase the probability of tile bulging.

4 Wall tile paving specification process

4.1 Process

Substrate cleaning→ material mixing→ wall scraping→ backing roller coating→ brick back scraping→ kneading pressure adjustment→ full pulp check→ finished product protection

4.2 Construction precautions

(1) grass-roots cleanup: focus on the cleanup of the dust and oil on the wall; after the cleanup is completed, the elevation control line, horizontal division line, squareness control line, vertical line, etc. will be popped.

(2) Material mixing: the material should be mixed in strict accordance with the ratio provided by the factory, focusing on the control of water and mixing time.

(3) wall scraping: focus on scraping thickness and scraping area; scraping thickness cannot too thick, and scraping area cannot be too large.

(4) Backing roller coating: backing roller coating needs to dry for not less than 24 hours after completion and should be used only after the slurry is dry.

(5) Brick back scraping slurry: brick back scraping slurry needs full scraping, using tooth plate scraping, and is easy to combine.

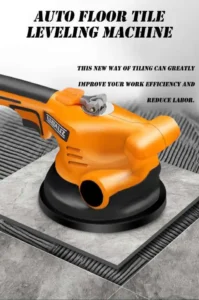

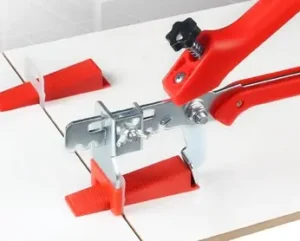

(6) Knead pressure adjustment: it is recommended to use an electric tile vibration machine to fully knead pressure and, with a tile leveling system, control flatness.

(7) Full pulp check: the full pulp rate shall not be less than 95% to ensure that the mastic is uniform and full.

(8) Finished product protection: Finished product protection needs to be protected by full coverage of wear-resistant anti-collision material.

4.3 Wrong Practice

Tile adhesive scraping is too thick, tile soaking water is not dried, tile back dust is not cleaned, tile adhesive landing mix is not dense, tile adhesive curing with water to continue to use, tile adhesive to participate in 108 glue or cement, cloth pulp area led to drying time is too strong, and tile paving does not leave seams. Some of the above common wrong practices, to a certain extent, lead to batch finishing process tile large area hollow drum quality accidents.

5 New processes bring new requirements

In recent years, with the development of construction technology, more and more new construction technology has been used in various projects over a large area to promote its use. The use of aluminum alloy formwork, assembly-type structures, and other processes improve the molding quality of a structure to meet the requirements of plaster-free, making the overall concrete molding surface smoother.

Second structure flatness and verticality measured pass rate increased significantly. Plastering only requires thin plaster to meet the requirements of previous deliveries. However, plaster-free structural base surfaces are smooth, have poor adhesion, and base surface release agent cleaning is more difficult. Thin plaster emits moisture quickly, so the thin plaster wall before tile construction needs to be pulled to test. Both a smooth structural base surface and the plaster surface adhesive's ability to weaken have greatly increased the risk of tile bulging.

The development of new process technology has put forward higher requirements for the control of tile paving drums, and finishing units need to have more modern management methods and process enhancements to cope with the new challenges posed by the development of modern building construction techniques.

6 Conclusion

To ensure impeccable results and minimize the occurrence of tile drums, it is crucial to choose high-quality materials and implement effective project management practices. Awisdom offers top-notch tile accessories and tools, along with professional guidance, to streamline your construction process. By selecting our products and services, you gain the advantage of reducing the probability of hollow drums and achieving superior project outcomes. Trust in Awisdom for exceptional quality and comprehensive support throughout your construction journey.