Installing vinyl plank flooring can be a straightforward process, but common mistakes can lead to costly repairs and aesthetic issues. In this article, we'll explore the 7 common mistakes when installing vinyl plank flooring, ensuring a successful and professional-looking installation that lasts.

Mistake #1: Not Sinking Fasteners

One of the most common mistakes when installing vinyl plank flooring is not sinking fasteners properly. Fasteners, such as nails or staples, that are not fully sunk into the subfloor can cause several issues:

- Uneven Surface: Protruding fasteners can create an uneven surface, making it difficult to lay the vinyl planks flat. This can lead to gaps between the planks and the subfloor, compromising the integrity of the flooring.

- Damage to Planks: If the fasteners are not fully sunk, they can puncture or scratch the vinyl planks during installation, necessitating costly replacements.

- Noise and Movement: Over time, the fasteners can work their way loose, causing the flooring to shift and creak, which can be particularly bothersome in high-traffic areas.

How to Avoid This Mistake

To ensure a smooth and even surface for your vinyl plank flooring, follow these steps:

- Inspect the Subfloor: Before installing the underlayment or vinyl planks, thoroughly inspect the subfloor for any protruding fasteners.

- Sink Fasteners: Use a hammer or a nail set to sink all fasteners below the surface of the subfloor. Ensure they are fully embedded to prevent any interference with the flooring.

- Fill Holes: If any holes are created by sinking fasteners, fill them with a suitable filler and sand smooth to ensure a flat surface.

- Check Again: After sinking all fasteners and filling any holes, re-inspect the subfloor to ensure it is smooth and even.

Mistake #2: Leaving Baseboards Installed

Another common mistake when installing vinyl plank flooring is leaving the baseboards in place. Baseboards are the trim pieces that cover the gap between the wall and the floor. Leaving them installed during the flooring installation process can lead to several issues:

- Inadequate Expansion Gaps: Vinyl plank flooring needs room to expand and contract with temperature changes. Leaving baseboards in place can prevent the creation of necessary expansion gaps, leading to buckling or warping of the flooring.

- Difficulty in Installation: Baseboards can make it challenging to fit the vinyl planks snugly against the wall, potentially causing gaps or uneven edges.

- Aesthetic Issues: If the baseboards are not removed, the new flooring may not fit flush against them, creating an uneven look that can detract from the overall appearance of the room.

How to Avoid This Mistake

To ensure a professional-looking installation and prevent potential issues, follow these steps:

- Remove Baseboards: Before installing the vinyl plank flooring, remove all baseboards from the room. This will give you clear access to the wall and allow for proper expansion gaps.

- Inspect and Clean: Inspect the area where the baseboards were removed for any debris or old adhesive. Clean the area thoroughly to ensure a smooth surface for the new flooring.

- Install New Baseboards: After the vinyl plank flooring is installed, put new baseboards in place. Ensure they are securely fastened to the wall and fit snugly over the expansion gaps.

- Add Quarter Round: Install quarter round molding over the expansion gaps between the baseboards and the flooring. This will cover the gaps and provide a finished look.

Mistake #3: Not Leveling the Subfloor

One of the most critical steps in installing vinyl plank flooring is ensuring the subfloor is level and even. A subfloor that is not properly leveled can lead to a variety of issues, including:

- Uneven Flooring: If the subfloor is not level, the vinyl planks will not lie flat, resulting in an uneven surface that can be both aesthetically unpleasing and potentially hazardous.

- Gaps and Cracks: Uneven subfloors can cause gaps and cracks in the flooring over time, as the planks may shift or bend to accommodate the uneven surface.

- Premature Wear: An uneven subfloor can lead to premature wear on the flooring, as certain areas may bear more weight or stress than others, reducing the overall lifespan of the flooring.

How to Avoid This Mistake

To ensure a level and even subfloor for your vinyl plank flooring, follow these steps:

- Inspect the Subfloor: Before installing the underlayment or vinyl planks, thoroughly inspect the subfloor for any unevenness, cracks, or damage.

- Use a Leveling Compound: If the subfloor is concrete, use a self-leveling compound to fill in any low spots and create a smooth surface. For wooden subfloors, use a wood filler to fill in any gaps or cracks.

- Check with a Laser Level: Use a laser level to ensure the subfloor is perfectly level. This tool will provide a precise measurement of any deviations from level.

- Sand the Subfloor: Once any fillers or compounds have dried, sand the subfloor to create a smooth, even surface. This will help ensure the vinyl planks fit snugly and evenly.

- Recheck the Subfloor: After sanding, recheck the subfloor with a laser level to ensure it remains level and even.

Mistake #4: Not Undercutting Door Jamb and Trim

Failing to undercut door jambs and trim is a common oversight when installing vinyl plank flooring. This mistake can lead to several issues:

- Gaps and Cracks: Without proper undercutting, the flooring may not fit snugly under the door jambs and trim, resulting in gaps and cracks that can compromise the integrity of the flooring.

- Difficulty in Installation: Trying to force the flooring under the door jambs and trim without undercutting can be challenging and may cause damage to the flooring or the surrounding area.

- Aesthetic Issues: Visible gaps between the flooring and the door jambs or trim can detract from the overall appearance of the room.

How to Avoid This Mistake

To ensure a seamless fit and prevent potential issues, follow these steps:

- Measure and Mark: Measure the thickness of the vinyl plank flooring and mark the door jambs and trim accordingly.

- Undercut the Jambs and Trim: Use a jamb saw or a coping saw to undercut the door jambs and trim to the marked depth. This will create enough space for the flooring to fit snugly underneath.

- Check the Fit: Before installing the flooring, check the fit by placing a plank under the door jamb or trim to ensure it fits smoothly and evenly.

- Install the Flooring: Once the door jambs and trim are properly undercut, proceed with installing the vinyl plank flooring, ensuring it fits tightly under the jambs and trim.

Mistake #5: Ending Rows with Small Boards

Ending rows with small boards is a common mistake when installing vinyl plank flooring. This can lead to several issues:

- Aesthetic Issues: Small boards at the end of rows can create an uneven and unappealing look, especially in larger rooms.

- Structural Integrity: Using small boards can compromise the structural integrity of the flooring, as they may not provide the same level of support as full-sized planks.

- Installation Challenges: Trying to fit small boards into place can be challenging and may require additional cuts or adjustments, which can be time-consuming and frustrating.

How to Avoid This Mistake

To ensure a professional-looking installation and prevent potential issues, follow these steps:

- Plan Ahead: Before starting the installation, plan the layout of the flooring to ensure that rows end with full-sized planks.

- Measure and Calculate: Measure the room and calculate the number of planks needed for each row, taking into account the width of the planks and the spacing between them.

- Use a Starter Row: Consider using a starter row, which is a row of planks that is installed perpendicular to the main direction of the flooring. This can help to create a more even and balanced look.

- Cut Planks Carefully: If it is necessary to cut planks to fit at the end of a row, use a miter saw or a circular saw to make precise cuts, and ensure that the cut planks are securely fastened to the subfloor.

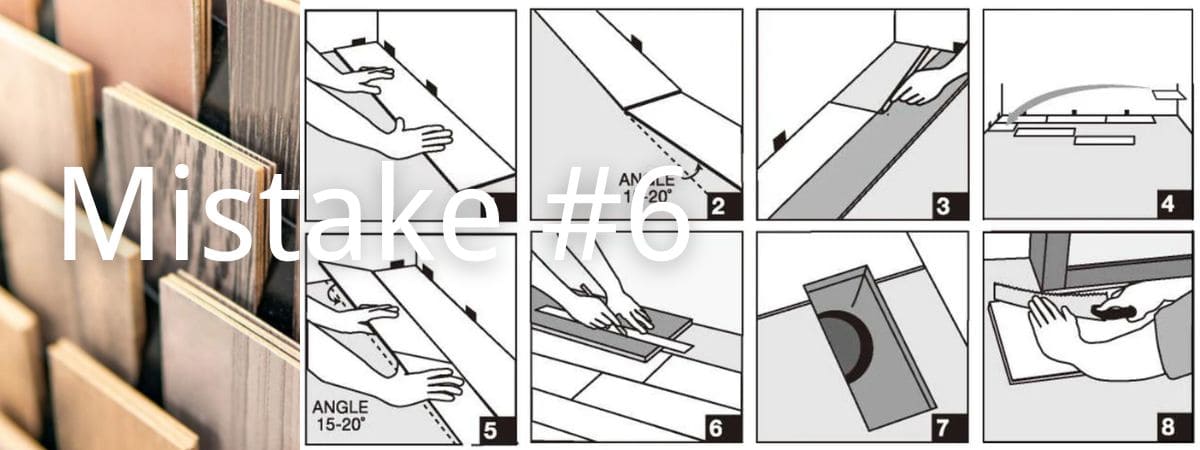

Mistake #6: Not Following Manufacturer Recommendations

Not following the manufacturer's recommendations for vinyl plank flooring installation can lead to several issues, including:

- Voiding Warranty: Failure to follow the manufacturer's guidelines can void the warranty, leaving you with no recourse if problems arise.

- Installation Errors: Ignoring manufacturer recommendations can result in incorrect installation methods, leading to issues such as uneven flooring, gaps, and premature wear.

- Incompatibility Issues: Using the wrong underlayment or adhesive can cause incompatibility issues with the flooring, leading to adhesion failures or other problems.

How to Avoid This Mistake

To ensure a successful installation and maintain the warranty, follow these steps:

- Read the Instructions: Carefully read and understand the manufacturer's installation instructions before starting the project.

- Use Recommended Materials: Use the underlayment, adhesive, and other materials recommended by the manufacturer to ensure compatibility and performance.

- Follow Installation Guidelines: Adhere to the manufacturer's installation guidelines, including any specific requirements for subfloor preparation, acclimation, and expansion gaps.

- Contact the Manufacturer: If you have any questions or concerns, contact the manufacturer for clarification or additional guidance.

Mistake #7: Not Acclimating Flooring

Not acclimating vinyl plank flooring before installation is a critical mistake that can lead to several issues, including warping, buckling, and gaps between planks. Acclimation is the process of allowing the flooring to adjust to the temperature and humidity levels of the installation space.

Why Acclimation Matters

Vinyl plank flooring is sensitive to environmental conditions, particularly temperature and humidity. When the flooring is not acclimated, it can expand or contract significantly, leading to:

- Warping and Buckling: Planks may warp or buckle as they adjust to the new environment, causing uneven surfaces and potential damage.

- Gaps Between Planks: Without proper acclimation, planks may shrink, leaving unsightly gaps between them.

- Adhesive Failure: Changes in plank size can lead to adhesive failure and loose planks if the flooring is glued down.

How to Acclimate Vinyl Plank Flooring

To ensure a successful installation, follow these steps for acclimating your vinyl plank flooring:

- Room Conditions: Ensure the room is at a stable temperature and humidity level, similar to the conditions you usually have in your home.

- Unpack the Planks: Remove the vinyl planks from their packaging to expose them to the room's climate.

- Lay Them Flat: Spread out the planks flat on the floor, avoiding direct sunlight or extreme temperatures.

- Time Frame: Acclimate the flooring for at least 48 hours, or as recommended by the manufacturer.

- Check Manufacturer's Instructions: Always refer to the manufacturer’s guidelines for the recommended acclimation time and conditions for your specific flooring product.

FAQ: Common Mistakes When Installing Vinyl Plank Flooring

What are the common mistakes when installing vinyl plank flooring?

Common mistakes include not sinking fasteners, leaving baseboards installed, failing to level the subfloor, not undercutting door jambs and trim, ending rows with small boards, not following manufacturer recommendations, and not acclimating the flooring.

How can I avoid gaps in vinyl plank flooring?

To avoid gaps, ensure the subfloor is level, acclimate the flooring to the room's temperature and humidity, and follow manufacturer guidelines for installation and expansion gaps.

Why is it important to undercut door jambs when installing vinyl plank flooring?

Undercutting door jambs allows the flooring to fit snugly beneath, preventing gaps and ensuring a seamless transition between rooms.

What should I do if my vinyl plank flooring is buckling?

Buckling can occur due to inadequate expansion gaps or improper acclimation. Ensure proper spacing and acclimate the flooring before installation to prevent this issue.

How do I ensure a professional-looking finish when installing vinyl plank flooring?

Follow manufacturer recommendations, plan the layout to avoid small end pieces, and ensure the subfloor is level and free of debris for a smooth installation.

What should you not use on vinyl plank flooring?

Avoid using ammonia or ammonia-based products, rubbing alcohol, steel wool, harsh abrasive cleaners, and polish on textured vinyl planks or tiles. Additionally, do not use steam mops or steam cleaning machines, as they can cause warping and adhesive issues.

Can you walk on vinyl plank flooring after installation?

Yes, you can walk on vinyl plank flooring after installation. However, it is recommended to wait at least 24 hours to allow the adhesive to fully set and the flooring to acclimate to the environment.

Can a beginner install vinyl plank flooring?

Yes, a beginner can install vinyl plank flooring. Vinyl plank flooring is considered one of the easiest DIY flooring options, with a click-together installation method that can be completed in a single afternoon.

How many hours does it take to install vinyl plank flooring?

The installation time for vinyl plank flooring can vary depending on the size of the space and the number of installers. However, on average, it can take around 2-4 hours to install vinyl plank flooring in a single room.