The final measure of a drywall finish is not found on the vast, flat walls, but at the corners where they meet. Without proper reinforcement, these exposed gypsum edges will inevitably chip, dent, and degrade over time, undermining an otherwise perfect surface. This guide details the different drywall corner bead types, providing the practical knowledge to select the precise material and profile that prevents this damage and ensures a professional result that lasts.

What Is Drywall Corner Bead?

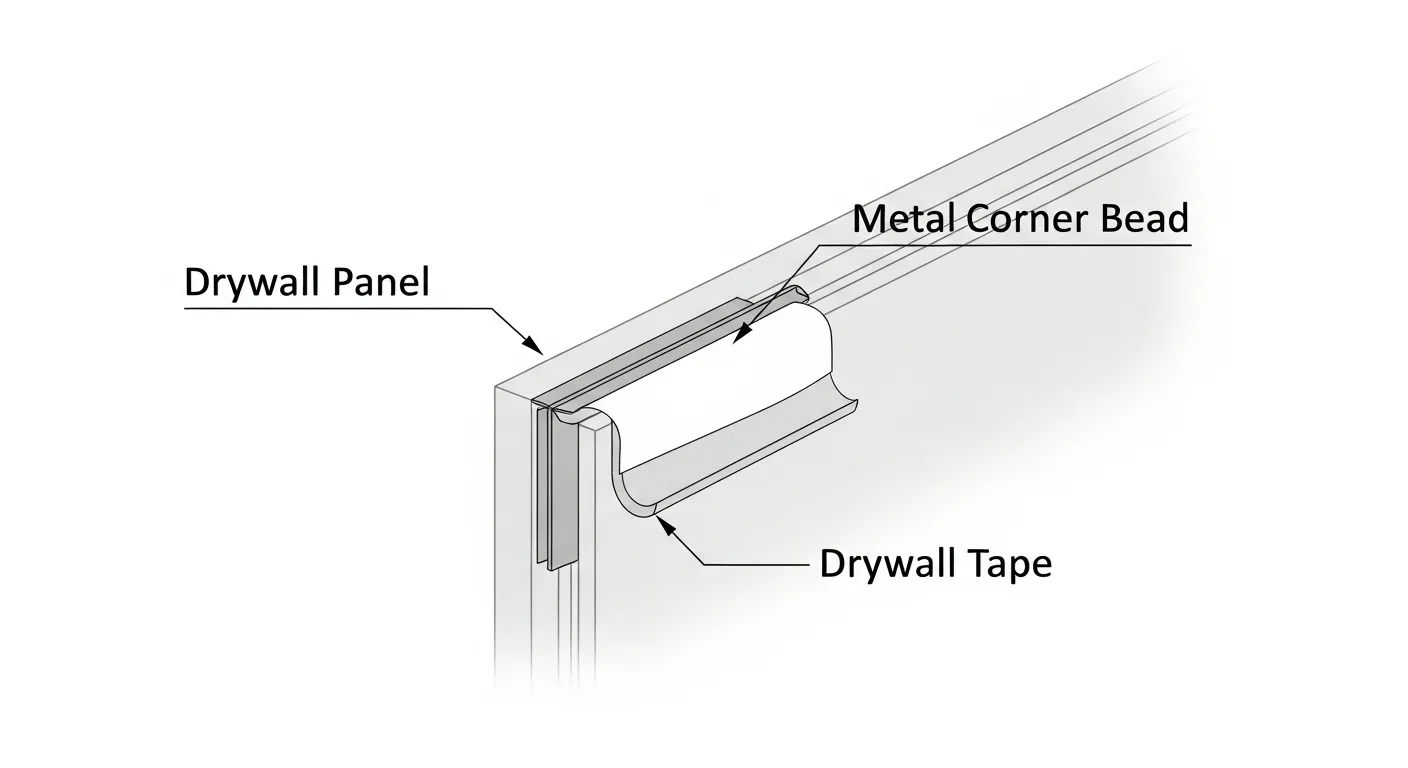

A drywall corner bead is a rigid profile installed on the outside corners of drywall panels. Its function is twofold. First, it armors the raw, brittle edge of the cut gypsum board, which would otherwise be highly susceptible to damage. Second, it acts as a precise guide for the application of joint compound, ensuring a straight, crisp, and durable corner. In the building trades, it is also frequently referred to as an "angle bead."

Understanding Corner Bead Materials

Corner bead materials are best understood as three distinct systems: metal, vinyl, and paper-faced. Each system excels at solving a different problem on the job site. The correct choice depends entirely on the project's priorities, whether that is enforcing a perfectly straight line, providing maximum impact resistance, or creating a flawless, crack-proof finish.

Quick Comparison: Metal vs. Vinyl vs. Paper-Faced

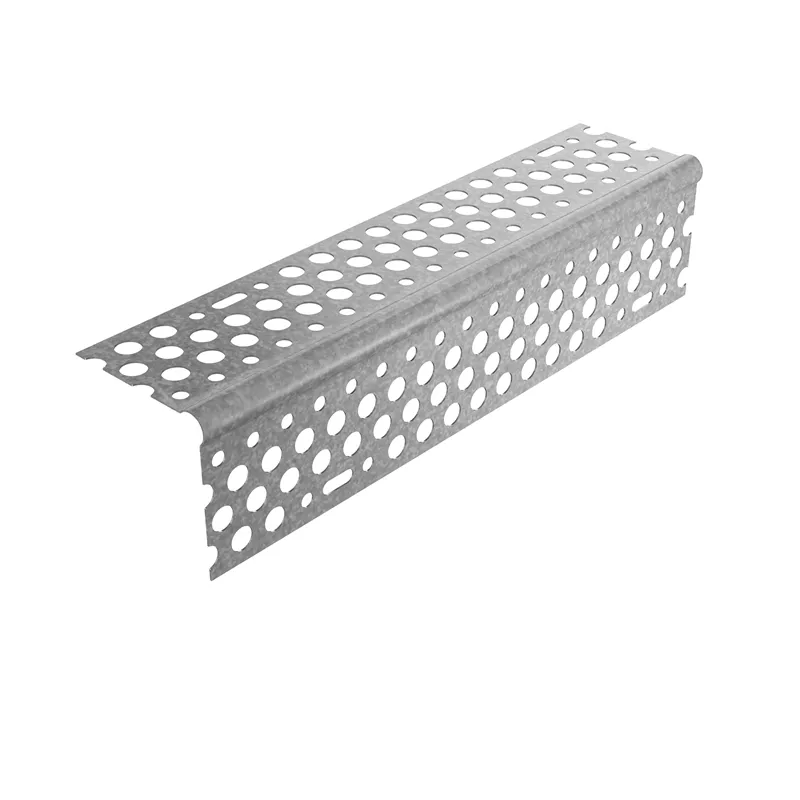

Metal Corner Bead

Metal corner bead is defined by its rigidity. This stiffness is a key feature that experienced installers use to their advantage, as it can bridge small gaps and help correct for minor imperfections in the underlying wood or steel framing. The most common type is made from galvanized steel, which has a zinc coating for a baseline level of rust resistance. This makes it a reliable choice for standard interior walls in low-traffic areas where achieving a perfectly straight line is the top priority.

Its primary weakness, however, is a permanent vulnerability to impact. A sharp blow from a piece of furniture or a vacuum cleaner will create a dent that cannot be repaired; the only remedy is to cut out and replace the damaged section. Furthermore, in persistently damp environments, the zinc coating can eventually be compromised, allowing rust to form and bleed through the paint.

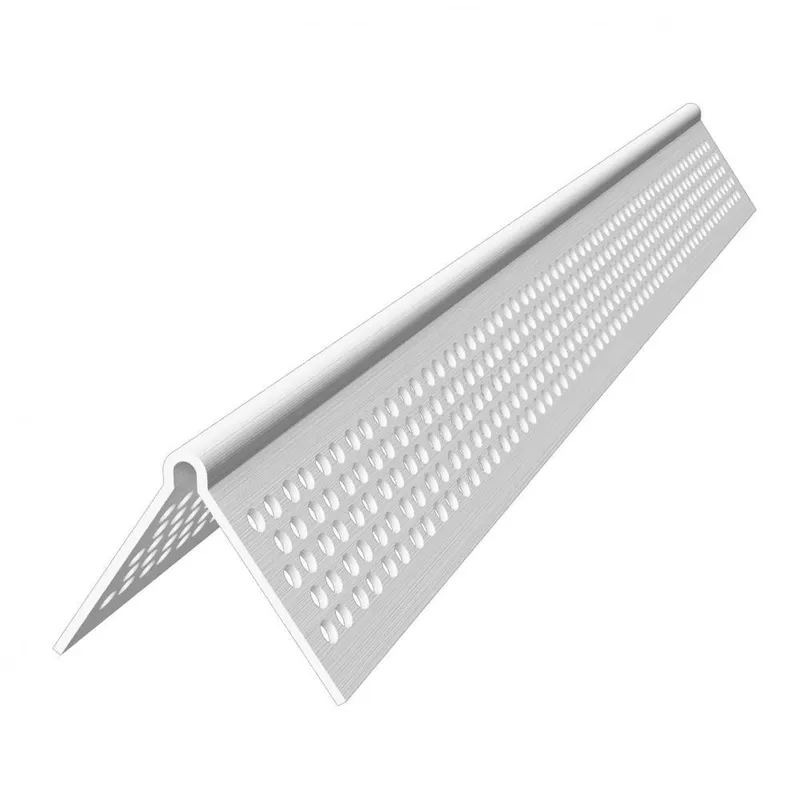

Vinyl Corner Bead

In direct contrast to metal's rigidity, vinyl corner bead is engineered for resilience. Manufactured from a durable PVC polymer, its core attribute is the ability to absorb impact and then return to its original shape. This quality makes it the superior material for any area prone to damage, such as hallways, garages, and commercial spaces.

Vinyl is also completely immune to rust, making it the required choice for all moisture-prone environments, including bathrooms, basements, laundry rooms, and coastal properties. The trade-off for this durability lies in the finishing process. The smooth plastic surface requires careful application of joint compound and often wider feathering with a taping knife to create a seamless transition from the bead to the wall surface.

Paper-Faced Corner Bead

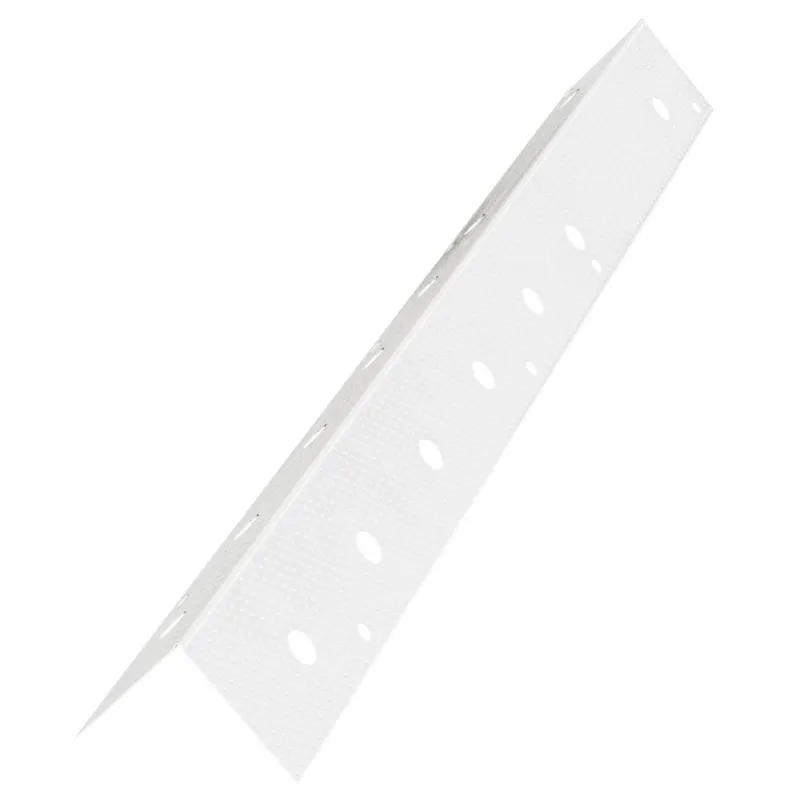

This product was developed specifically to solve the most common failures of traditional nail-on metal beads: edge cracking and "nail pops." It consists of a structural core, made of either metal or a composite plastic, which is laminated to wide paper flanges.

Instead of being fastened with nails or screws, the bead is installed by embedding the paper flanges into a bed of joint compound, creating a continuous, monolithic bond with the drywall. This eliminates stress points and makes the corner highly resistant to developing hairline cracks as a building settles. Its performance, however, is entirely dependent on correct installation. If the joint compound is mixed improperly or applied too thinly, air bubbles can become trapped under the paper, a common frustration for inexperienced users.

Common Corner Bead Shapes and Their Applications

Beyond the material, the physical shape of the bead, its profile, is chosen to solve a specific problem on the job. A professional diagnoses the corner's condition and its architectural purpose, then prescribes the correct profile. This is not about picking from a list; it is about applying the right tool for the task.

Square Corner Bead

This is the workhorse for standard 90-degree outside corners. Its singular purpose is to deliver a crisp, sharp line. It is the default, baseline choice for most interior walls.

Bullnose Corner Bead

This profile creates a soft, rounded corner for a more modern or high-end aesthetic. However, its use requires forward planning. Standard baseboard and crown molding cannot sit flush against its curve. This forces a choice: either the carpenter must execute complex miter cuts, or the designer must specify purpose-built transition blocks to resolve the intersection cleanly. Ignoring this detail leads to unsightly gaps.

Chamfer Corner Bead

This bead offers a middle ground between a sharp point and a soft curve, forming a clean, 45-degree angled corner. It is a deliberate stylistic choice, used to add a subtle, geometric detail to a room's design.

L-Bead

An L-bead is a finishing trim, not a corner reinforcement. It is used where a sheet of drywall terminates against a different surface, such as a brick wall, a steel beam, or a window frame. One flange of the bead covers the raw drywall edge while the other lies flat on the face of the drywall. This flat flange is then covered with joint compound, allowing for a smooth, feathered transition from the wall to the finished edge.

J-Bead

Like an L-bead, a J-bead is used to finish a raw drywall edge. The critical difference is its shape and application. A J-bead fully encapsulates the edge of the drywall in a "J" shaped channel. It provides a clean, finished look by itself and is not designed to be covered with joint compound. This makes it a fast and simple solution for areas like the termination point of a partition wall or around un-trimmed window openings.

L-Bead vs. J-Bead: Which Edge Trim to Use?

Both L-Bead and J-Bead are used to finish the raw edge of a drywall panel where it meets another surface. The choice between them depends entirely on the desired final look and installation speed.

Archway Corner Bead

Attempting to bend a rigid bead around a curve results in a faceted, unprofessional finish. An archway bead, usually made of vinyl, is specifically engineered with notched flanges. These notches allow it to conform perfectly to a radius, ensuring a smooth, graceful curve without kinks or flat spots. It is the only professional solution for arched doorways and windows.

Splayed & Flexible Off-Angle Bead

Standard 90-degree beads are useless for the obtuse angles common in bay windows or the acute angles in vaulted ceilings. The professional solution is twofold: a rigid splayed bead is pre-formed to a specific angle (e.g., 135°) for common situations, guaranteeing a perfectly straight line. For custom angles, a flexible composite tape is superior, as it can be folded to match any angle precisely.

Reveal & Shadow Bead

These are not for protection but for design. An architect uses these profiles to transform a flat wall into a deliberate architectural element. They create clean, crisp recesses (reveals) or shadow lines, often serving as a modern, high-end replacement for traditional baseboards or door trims.

Expansion & Control Joints

This profile is a non-negotiable structural requirement, not an option. Building codes mandate its use in long, uninterrupted drywall runs (typically over 30 feet). Its purpose is to create a designed point of separation that safely absorbs building movement and thermal stress. Omitting it doesn't save money; it guarantees that the stress will find its own release point, resulting in inevitable and costly random cracking across the wall.

Key Installation Tips for a Professional Finish

The highest quality corner bead will fail if it is installed incorrectly. The material you choose dictates the installation system you must use. Getting these fundamental steps right is what separates a durable, long-lasting corner from one that is prone to cracking and failure.

Choosing the Right Fastening Method

- For Metal Bead: Use coarse-thread drywall screws or ring-shank nails, spaced every 8 to 12 inches. Many experienced professionals prefer nails, as their small heads are easier to conceal and are less likely to twist or deform the bead's flange upon installation.

- For Vinyl Bead: The accepted best practice is a hybrid approach. First, apply a specialized spray adhesive to both the bead and the drywall. Press the bead into place, then immediately secure it with half-inch divergent staples every 6 to 8 inches. The staples provide an immediate mechanical hold, keeping the bead perfectly straight while the adhesive cures to form a powerful, continuous bond.

- For Paper-Faced Bead: This system does not use mechanical fasteners. It must be installed by embedding the paper flanges into a bed of joint compound. The compound itself is the adhesive.

Why Professionals Use Setting-Type Compound ("Hot Mud")

For the critical first coat that adheres a paper-faced bead or covers a metal bead, professionals overwhelmingly use a setting-type compound, commonly called "hot mud." Unlike pre-mixed all-purpose compounds which dry through slow evaporation, hot mud cures through a fast chemical reaction. This provides three distinct advantages:

- Superior Bond Strength: It creates a significantly harder, more durable bond.

- Minimal Shrinkage: It does not shrink as it cures, which prevents it from pulling on the bead, distorting its shape, or causing hairline cracks.

- Speed: It sets quickly (in 20, 45, or 90 minutes, depending on the product), allowing a finisher to apply subsequent coats the same day, a critical factor for job site efficiency.

The Secret to Avoiding Bubbles with Paper-Faced Bead

The single most common failure for DIY users of paper-faced bead is bubbling under the paper flanges. This is not a product defect; it is an installation error caused by air getting trapped between the paper and the drywall. The secret to preventing this is a two-part process:

- Proper Mud Consistency: The joint compound must be mixed to a smooth, creamy consistency, free of lumps, similar to a thick pancake batter.

- Correct Application: Apply a generous, even bed of mud to the corner. Press the bead firmly into the mud, and as you wipe away the excess, use a taping knife with light, consistent pressure. Wiping too hard will "starve" the paper of the compound it needs to adhere, guaranteeing bubbles will form.

How to Choose the Right Bead for Your Project

This is where experience is applied. The right bead is the one that best solves the specific challenges of its location.

For High-Traffic Hallways

Vinyl is the only logical choice. Its ability to flex under impact and return to its shape means it can withstand years of abuse from carts, furniture, and people. A metal bead in the same location would accumulate permanent dents, requiring costly repairs.

For Bathrooms and Basements

Vinyl is mandatory. It is completely waterproof and will never rust. A standard galvanized metal bead, when its protective coating is inevitably scratched during installation or sanding, will eventually rust in the humid environment. This rust will bleed through the mud and paint, creating an ugly yellow or brown stain that is impossible to remove.

For a Perfect Arch

A dedicated, flexible archway bead is required. Do not attempt to make a series of relief cuts in a rigid bead. This amateur technique always results in a faceted, uneven appearance rather than a true, graceful curve. The purpose-built archway bead is engineered to prevent this.

For an Advanced, Crack-Proof Finish

For maximum durability on a standard metal bead, use the professional "tape-over" technique. After nailing the bead in place, apply standard drywall tape over the metal flanges, embedding it in compound just as you would a flat seam. This creates a flexible bridge between the rigid metal and the drywall, making the corner virtually immune to the hairline cracks that can form from building movement.

A Note on the True Cost

When evaluating corner bead, looking solely at the per-foot price is a common but costly mistake. The true cost of a corner is a calculation that must include material waste and the long-term risk of repairs.

Metal corner bead, while often having the lowest initial price, is highly susceptible to damage during shipping and handling on a busy job site. It is common for a significant percentage of a box to be too bent or dented to be usable, driving up the effective material cost. Vinyl, by contrast, is far more resilient and has a near-zero waste factor.

More importantly, labor is the largest expense in any drywall project. The cost to have a professional return to a finished job to repair a single dent in a metal corner can easily erase any initial savings. Therefore, investing in a more durable, impact-resistant vinyl bead for a high-traffic area is not an expense; it is an insurance policy against future costs.

Frequently Asked Questions

What is the difference between a corner bead and an angle bead?

There is no difference. "Angle bead" is another professional term for a drywall corner bead. The terms are used interchangeably in the building trades to refer to the same product used to protect outside corners.

Do you use corner bead on inside corners?

Typically, no. Most inside corners are finished simply with folded paper or composite drywall tape embedded in joint compound. This method is sufficient for reinforcing inside corners, which are not subject to the same impact and wear as exposed outside corners.

What corner bead is best for ceilings?

The choice depends on the room's environment. For most standard flat ceilings, a metal or paper-faced bead provides the necessary rigidity. However, for ceilings in bathrooms, basements, or other high-humidity areas, a vinyl corner bead is the correct choice to prevent any possibility of future rust stains appearing on the painted surface.

Is it necessary to tape over a metal corner bead?

It is not strictly required, but it is a highly recommended professional technique for ensuring maximum long-term durability. Taping over the metal flanges creates a flexible bridge to the drywall surface, which makes the corner significantly more resistant to developing hairline cracks from minor building movement over time.