Choosing the right flooring for your home involves comparing various options, among which engineered wood flooring and laminate flooring are popular choices. This comparison article delves into the key differences, pros, and cons of engineered wood flooring vs laminate flooring, providing a detailed overview to inform your decision-making process. Discover which flooring type best suits your aesthetic preferences, durability needs, and budget constraints.

Key Differences: Engineered Wood Flooring vs Laminate

Feature | Engineered Hardwood | Laminate Flooring |

|---|---|---|

Composition | Real wood veneer + HDF core | Synthetic, photographic layer |

Appearance | Natural wood look | Wood-like, less realistic |

Durability | 20-30 years, up to 100 | 10-20 years |

Scratch Resistance | Moderate | High |

Maintenance | Can be refinished | Replace if damaged |

Water Resistance | Moderate, varies | High, vulnerable at seams |

Cost | Higher | Lower |

Installation | Professional recommended | Easier, DIY-friendly |

Resale Value | Higher | Lower |

What is Engineered Flooring

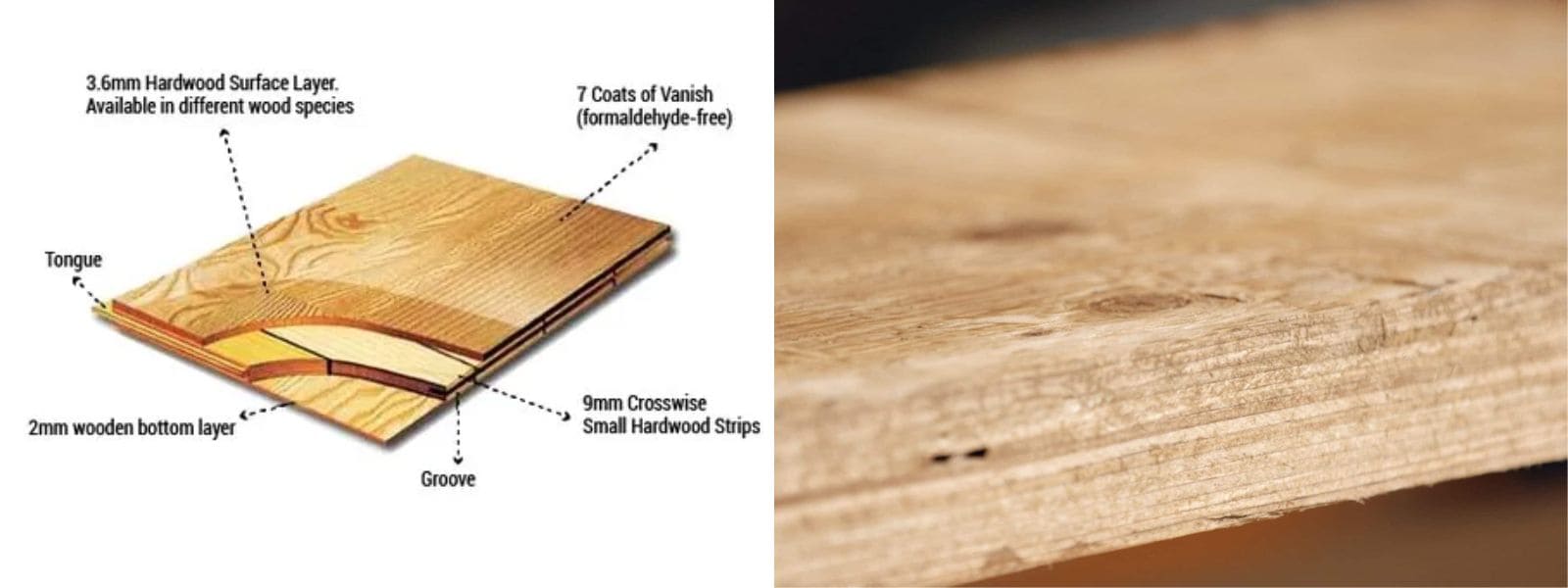

Engineered hardwood flooring is a versatile and durable flooring option that consists of multiple layers of wood, each layer positioned in different directions to enhance stability and prevent warping. This construction allows for installation across all levels of a home, including below ground with a moisture barrier.

Unlike traditional hardwood, which is made from solid wood planks, engineered hardwood features a top layer of hardwood veneer, giving it the natural beauty of wood while being more adaptable to various environments.

Pros of Engineered Hardwood Flooring

- Cost-Effective: Generally less expensive than traditional hardwood, engineered hardwood offers significant savings, especially because it often comes prefinished and requires less labor for installation.

- Durability: Engineered hardwood is designed to resist warping and moisture damage, making it suitable for a wider range of environments, including basements and over radiant heating systems.

- Aesthetic Versatility: Available in various wood species and finishes, engineered hardwood can be tailored to match any decor style, from rustic to modern.

- Installation Flexibility: It can be installed over various subfloors, including concrete and existing wood floors, using different methods such as floating (no glue or nails needed), which can be a manageable DIY project.

Cons of Engineered Hardwood Flooring

- Refinishing Limitations: While it can be refinished, the number of times is limited compared to solid hardwood. Floors with thinner veneer layers might only withstand being refinished once or not at all.

- Longevity Concerns: Although durable, the lifespan of engineered hardwood can be shorter than solid hardwood, especially if it cannot be refinished multiple times.

- Potential for VOC Emissions: Some engineered hardwood products can emit volatile organic compounds (VOCs) due to the adhesives and materials used in their construction.

What is Laminate Flooring

Laminate flooring is a synthetic flooring product composed of multiple layers fused together, featuring a photographic applique layer under a clear protective layer. It mimics the appearance of wood (or stone) but at a lower cost and with greater resistance to scratches, making it suitable for areas with high foot traffic.

Pros of Laminate Flooring

- Affordability: It is one of the most cost-effective flooring solutions available, significantly cheaper than both engineered and solid hardwood floors.

- Durability and Maintenance: Laminate flooring is highly durable, resists scratches and wear, and is easy to clean and maintain.

- Ease of Installation: Known for its DIY-friendly installation, laminate flooring typically features a click-lock design that allows for quick, tool-free installation over an underlayment.

Cons of Laminate Flooring

- Cannot Be Refinished: Unlike wood, laminate flooring cannot be sanded or refinished. Once worn or damaged, it must be replaced.

- Authenticity and Feel: While high-quality laminates can closely mimic the look of wood, they do not feel the same underfoot and may not offer the same warmth and character.

- Water Sensitivity: While more resistant to moisture than traditional hardwood, laminate flooring can still be damaged by excessive moisture and is not recommended for bathrooms or areas prone to wet conditions.

What is the Difference between Engineered Hardwood and Laminate Flooring?

Engineered wood flooring and laminate flooring are two popular alternatives to solid hardwood flooring, but they have 7 key differences:

1. Composition and Structure

- Engineered hardwood consists of a real wood veneer layer bonded to a plywood or high-density fiberboard (HDF) core.

- Laminate flooring is made entirely of synthetic materials, with a photographic layer that mimics wood grain covered by a clear protective wear layer.

2. Appearance

- Engineered hardwood has a genuine wood surface, providing a more authentic and natural look.

- Laminate flooring simulates wood appearance but may look less realistic upon close inspection.

3. Durability and Lifespan

- Engineered hardwood typically lasts 20-30 years, with some high-quality options lasting up to 100 years.

- Laminate flooring generally has a shorter lifespan of 10-20 years.

- Laminate is more resistant to scratches and wear due to its protective top layer.

4. Maintenance and Repair

- Engineered hardwood can be sanded and refinished, though less frequently than solid hardwood.

- Laminate cannot be refinished and must be replaced if severely damaged.

5. Water Resistance

- Engineered hardwood offers better resistance to moisture and humidity than solid hardwood.

- Laminate is generally more water-resistant on the surface but can be damaged if water penetrates the seams.

6. Cost

- Laminate flooring is typically less expensive than engineered hardwood.

- Engineered hardwood prices are closer to those of solid hardwood.

7. Installation

- Laminate flooring is often easier to install as a DIY project, using a floating floor system with interlocking edges.

- Engineered hardwood usually requires professional installation and may be nailed down, glued, or installed as a floating floor.

8. Resale Value

- Engineered hardwood generally adds more value to a home compared to laminate flooring.

To sum up the above, engineered hardwood offers a more authentic wood appearance and can be refinished, but it comes at a higher cost. Laminate flooring provides better scratch resistance and water resistance at a lower price point but lacks the natural look and longevity of engineered hardwood. The choice between the two depends on factors such as budget, desired appearance, installation preferences, and the specific needs of the space.

How to Tell Whether the Floor is Solid Wood or Engineered Wood

Telling the difference between solid and engineered wood floors is simpler than you might think. Let's look at the easiest ways to check your flooring type.

Quick Ways to Check

Look at the edges of your floor where it meets the wall or in doorways. Solid hardwood shows one continuous piece of wood, while engineered wood displays layers stacked together like a sandwich.

Simple Tests You Can Do

Edge Check: Find a spot where the flooring edge is visible, like near a vent or under a cabinet. Solid wood shows the same wood grain all the way through. Engineered wood has distinct layers you can see from the side.

Thickness Test: Measure the board thickness at an exposed edge. Solid hardwood is usually 3/4 inch thick. Engineered boards are thinner, typically 3/8 to 9/16 inch thick.

Surface Feel: Press your fingernail into a hidden spot of the floor. Solid hardwood often shows a small dent, while engineered wood usually resists denting thanks to its protective finish.

Installation Clues

Check how the floor is attached. Solid hardwood needs nails and a wood subfloor. Engineered wood often floats over the subfloor or can be glued down, even on concrete.

Should I Use Transition Strips on Wood or Laminate Floors?

If you're installing new flooring, you may be contemplating whether transition strips are necessary for your wood or laminate floors. Let's cut through the noise and get to the facts.

Transition strips serve a fundamental purpose: they manage the natural expansion and contraction of flooring materials. As wood and laminate react to environmental changes, these strips help prevent the unsightly and potentially damaging effects of buckling or creating gaps between different flooring sections.

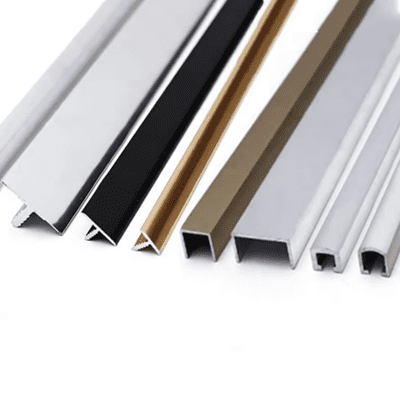

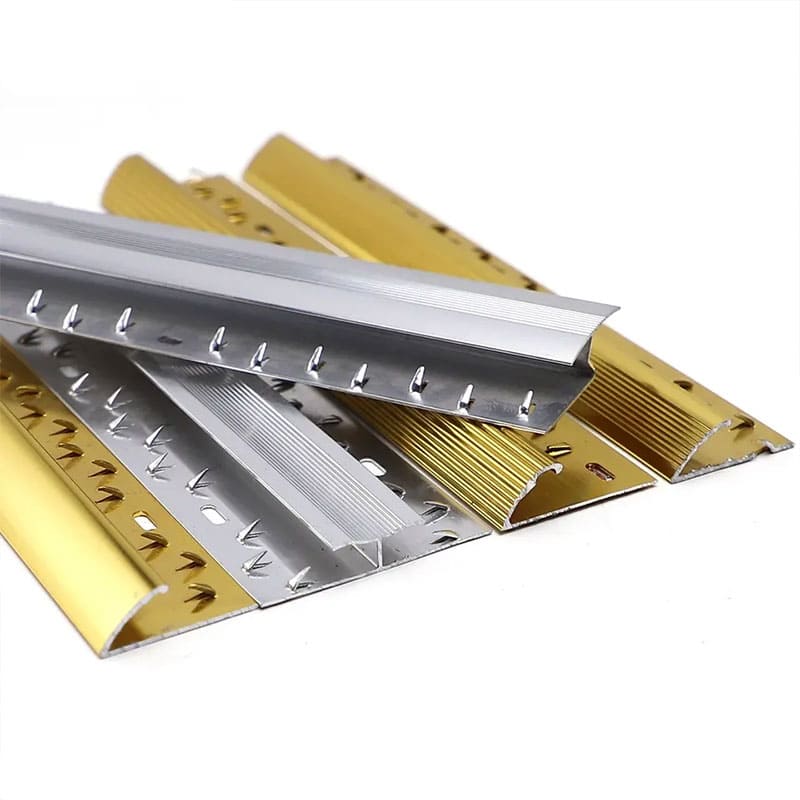

The choice of material for transition strips includes wood, metal, rubber, and vinyl. Each has its merits. Wood strips can be customized to match your floors for a coherent aesthetic, while metal offers durability with a variety of finish options to suit different decor styles. For areas with higher moisture levels, such as kitchens or basements, rubber or vinyl strips are advisable due to their resistance to water and flexibility.

Installation of transition strips is straightforward but requires precision. It involves measuring the space, cutting the strip to an exact fit, and ensuring it is securely attached to the subfloor rather than the flooring itself.

Usually, transition strips should be placed under doors or between different flooring types to ensure a seamless transition that is both visually appealing and safe. This not only enhances the installation's overall appearance but also contributes to the structural integrity of the flooring.

So, when planning your flooring installation, consider transition strips an integral part of the process. Ready to proceed? Ensure these components are factored into your installation strategy.

FAQs about Engineered Wood and Laminate Flooring

Do engineered wood floors scratch easily?

Engineered wood floors can scratch, similar to solid hardwood floors, because they have a top layer of real hardwood. The susceptibility to scratches depends on the type of wood used for the veneer. Harder woods like Hickory or Maple tend to be more resistant to scratches, while softer woods like Cherry or Walnut are more prone to scratching. Regular maintenance and using protective measures, such as felt pads under furniture, can help reduce the risk of scratches.

Which is more expensive: vinyl plank or engineered hardwood?

The cost of luxury vinyl planks (LVP) is generally lower than that of engineered hardwood floors. Typically, luxury vinyl planks cost between 1/2 to 2/3 of the price of engineered hardwood. This makes LVP a more budget-friendly option compared to engineered hardwood, though both are less expensive than solid hardwood floors.

What should you not put on engineered hardwood floors?

To maintain the integrity of engineered hardwood floors, avoid using harsh chemicals, ammonia-based cleaners, and excessive amounts of water. These substances can damage the wood and its finish. Instead, use cleaning products specifically designed for engineered hardwood floors, and ensure any cleaning method does not saturate the wood.

What is the most popular color of engineered wood flooring?

Light and medium brown shades are the most popular colors for engineered wood flooring. These tones highlight the natural grain of the wood and provide a bright, airy look that complements a wide range of interior styles. Variations in these colors can include mixed-color grains and minimal knotholes, adding character to the flooring.

Do you need padding under engineered hardwood floors?

Yes, installing an underlayment beneath engineered hardwood floors is recommended. Underlayment serves as a moisture barrier, helps in noise reduction, provides thermal insulation, and evens out minor subfloor imperfections. This additional layer supports the longevity of the engineered wood planks by preventing moisture build-up and providing extra stability.