What Is Aluminum Trim and Why Is It Important?

In any construction project, from residential apartments to high-end commercial centers, refinement is often determined by the smallest details. An elegant wood-paneled wall or a polished tile floor can lose its value if material edges are left exposed or if the transition between two surfaces feels awkward. This is precisely where aluminum trim demonstrates its indispensable role.

Essentially, aluminum trim consists of extruded profiles designed to cover, protect, and decorate the edges, corners, or joints of material surfaces. But that definition alone fails to capture its full importance. Aluminum trim serves a dual purpose: it is both a technical solution and an aesthetic enhancement. It protects the edges of engineered wood panels from chipping and moisture while also acting as a sophisticated metal inlay that adds character to a wall.

Therefore, selecting the correct type of aluminum trim is not merely about buying an accessory; it is a strategic decision that directly impacts the durability and beauty of an entire space. With advancements in technology, decorative aluminum trim has become its own design language—a powerful tool for architects and designers to turn creative ideas into reality, delivering a polished, professional look to any project.

Exploring Common Types of Aluminum Trim

The market for aluminum trim is diverse, with each profile engineered to solve specific challenges. A clear understanding of the features and applications of the most common types will help you make an accurate choice, optimizing for both function and cost. Below is a detailed analysis of the profiles you will encounter most frequently.

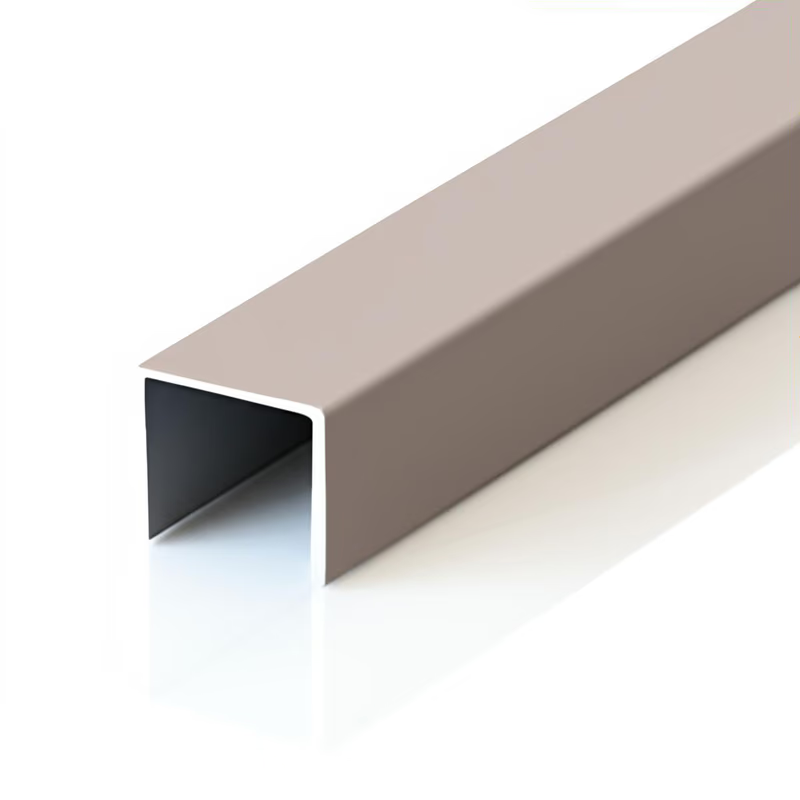

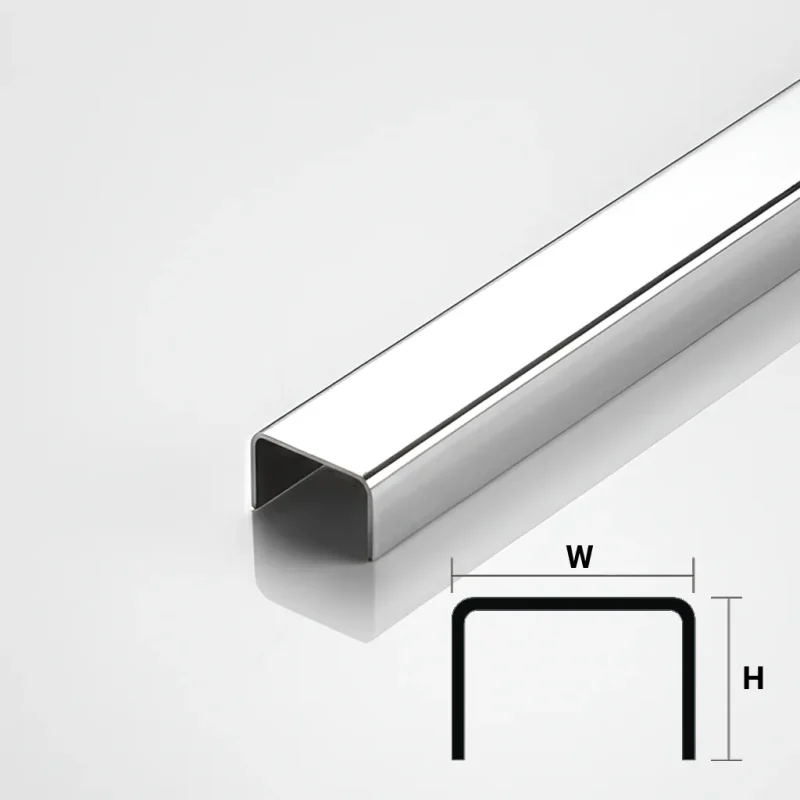

Aluminum U Channel: For Creating Sharp Inlay Details

The aluminum U channel, with its characteristic U-shaped cross-section, is the primary solution for finishing the edges of panels with a specific thickness. Instead of leaving the vulnerable core of engineered wood or stone composite panels exposed, the U channel neatly caps the edge, creating a robust barrier against impacts and moisture ingress.

However, the value of the U channel extends beyond protection. In modern interior design, it is widely used to create decorative inlay lines. By grooving a surface and recessing a U channel into a wall, partition, or cabinet door, designers can produce clean, sophisticated metallic stripes. This technique breaks the monotony of large surfaces, creates visual rhythm, and provides a subtle sense of luxury.

Practical Applications:

- Edging for kitchen and wardrobe doors: Prevents the edges of MDF or MFC panels from chipping during daily use.

- Creating decorative grooves on wall panels: Adds a modern touch to TV walls, headboards, or lobby areas.

- Finishing the edges of glass partitions: Provides a neat and secure frame for glass panels.

Aluminum V-Shaped Trim: The Solution for Every Corner

External 90-degree corners are the most vulnerable to impact in any building. A collision from a shopping cart, a suitcase in a hotel corridor, or a child's toy at home can cause chipping and damage to paint and plaster. The V-shaped aluminum trim was developed to solve this problem permanently.

With its V-shaped structure, this trim is installed directly onto an external corner, forming a durable metal shield. For high-traffic areas like parking garage columns or hospital corridors, using a V-shaped trim with a greater wall thickness is a cost-effective investment that reduces long-term maintenance and repair costs.

Furthermore, this profile is a powerful aid in tile installation. Instead of spending time and effort mitering two tile edges to form a 45-degree corner—a task requiring high skill and prone to error—installers can use a V-trim to create a perfect, sharp, and safer corner, especially in bathrooms. For this reason, it is also known as aluminum corner trim.

Practical Applications:

- Protecting wall corners and columns in lobbies and public hallways: Guards against impacts and scratches.

- Finishing tiled wall corners: Covers raw tile edges to create a safe and aesthetically pleasing corner.

- Framing decorative wall niches or shelving units.

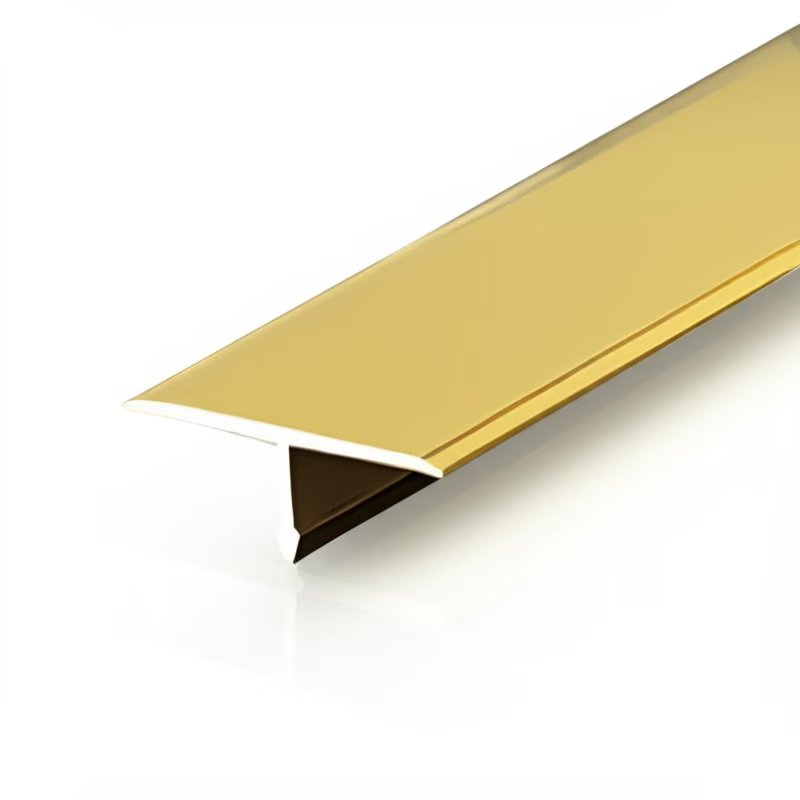

Aluminum T-Shaped Trim: For Smooth Material Transitions

Using different flooring materials in one space is common, such as wood flooring in a living room and tile in the kitchen. At the junction between these two materials, a small expansion gap is necessary to allow the wood floor to expand and contract with changes in temperature and humidity. If left open, this gap collects dirt and looks unfinished.

The aluminum T-shaped trim is perfectly designed to handle this situation. The stem of the "T" fits into the gap, while the top surface covers it, creating a clean and seamless transition between the two floor surfaces. It not only solves a technical requirement but also creates a decorative accent that clearly delineates the space.

Beyond its primary use on floors, the T-trim can also be used to create decorative lines on walls or large doors, similar to a U channel but with a more pronounced surface effect.

Practical Applications:

- Joining wood flooring with tile, stone, or carpet.

- Covering expansion gaps in large floor areas in commercial centers or offices.

- Creating decorative accents that separate different wall materials.

Aluminum L-Shaped Trim: For Finishing the Smallest Details

Versatility is the greatest strength of the L-shaped aluminum trim. Its simple yet effective shape allows it to be used in numerous finishing applications.

The most common use for an L-trim is as a floor edging profile. At locations where wood flooring meets doorways, balcony doors, or glass walls—places where skirting boards cannot be used—the L-trim provides a neat termination point, protecting the floor edge from exposure and warping.

Additionally, the L-trim is an excellent choice for capping 90-degree edges on furniture like tabletops, countertops, or stair treads. It offers a durable metal surface that resists wear and chipping far better than traditional edge banding, while also providing a modern and robust appearance.

Practical Applications:

- Finishing the edge of wood flooring at thresholds or balconies.

- Edging for tables, countertops, or stair treads.

- Framing for signboards or mirrors, providing a minimalist, industrial look.

A Guide to Selecting the Right Aluminum Trim

Once you are familiar with the basic trim types, the next step is to select the most suitable product for your project. This process requires careful consideration of three main factors: purpose, design style, and material requirements.

What Is Your Primary Goal for the Trim?

Clearly identifying your objective from the start will help you narrow down the options and find the most effective solution. Ask yourself what primary problem you need to solve.

- To protect high-impact areas: If your goal is to shield corners that are subject to frequent physical contact, prioritize trims with a solid structure. For instance, in a hotel corridor where luggage carts often pass, or a hospital corner where medical carts maneuver, an aluminum V-shaped trim with a wall thickness of 1.2mm or more is a sensible choice. Similarly, to ensure safety and protect the edge of a staircase, an anti-slip stair nosing profile with rubber inserts is irreplaceable.

- To address technical joints: When you need to cover expansion gaps in wood flooring or create a smooth transition between two materials, the aluminum T-shaped trim is the answer. Be sure to select a T-trim with a top width sufficient to completely cover the gap, ensuring a clean look and preventing dirt from falling through.

- To create decorative accents: When aesthetics are the main driver, you have more creative options. Small-profile U-channels or T-trims can be recessed into walls to create elegant, luxurious inlay lines. Additionally, advanced solutions like aluminum profiles for LED strips are increasingly popular. These profiles have a specially designed channel to house LED strips, creating indirect lighting effects on walls, ceilings, or under cabinets, adding a new dimension of depth to the space.

Which Color Palette Complements Your Space?

Aluminum trim is not just a functional component; it is an integral part of the overall design scheme. Choosing the right color will help create a more cohesive and intentional space.

- For Minimalist and Industrial styles: These styles emphasize simplicity, clean lines, and raw materials. Neutral-colored trims are therefore the top choice.

- Silver (natural aluminum finish): Offers a clean, technical look that is easy to coordinate with other colors.

- Matte Black: Creates a strong contrast for a bold and modern feel, especially when paired with concrete walls or light-colored wood.

- For Luxury and Neo-classic styles: These styles often use premium materials and warm tones to create a sense of elegance and opulence.

- Polished Gold / Matte Gold: A classic choice for creating accents, providing warmth and a sense of luxury.

- Champagne / Rose Gold: More modern interpretations of gold, offering a subtle, gentle, and fashionable look that pairs well with marble or upholstered furniture.

Why Should You Pay Attention to Material & Finish?

A beautiful appearance needs to be backed by intrinsic quality. The two factors that determine the durability of aluminum trim are the alloy composition and the surface treatment technology.

Most high-quality trims on the market are made from premium aluminum alloy, which provides the necessary rigidity while remaining ductile enough for easy fabrication and cutting during installation.

Even more important is the protective surface layer. In hot and humid climates, airborne moisture can easily penetrate beneath a standard paint layer, causing blistering and peeling over time. To overcome this, Anodizing technology is applied. This process does not involve painting a coating onto the surface; instead, it uses an electrochemical process to create an extremely hard and durable aluminum oxide layer. This film is an integral part of the aluminum itself and has a dense structure that completely seals the base metal from air and moisture. The result is a trim with superior resistance to corrosion and rust, ensuring it retains its original color and finish for many years.

Aluminum, Stainless Steel, or PVC Trim: Which Should You Choose?

Besides aluminum, other material options on the market include stainless steel and PVC. Each has its own advantages and disadvantages, and the best choice depends on your budget, installation location, and durability requirements. Aluminum trim is generally considered the most balanced option, offering optimal performance across multiple criteria.

Here is a quick comparison table to give you a clear overview:

Criteria | Anodized Aluminum Trim | Stainless Steel Trim (304) | PVC Trim |

|---|---|---|---|

Cost | Reasonable, balanced | High | Very Low |

Durability | Good, fair impact resistance, high corrosion resistance | Excellent, superior impact and chemical corrosion resistance | Low, becomes brittle, easily scratched |

Installation | Easy, lightweight, simple to cut | More difficult, harder and heavier | Very easy, flexible |

Aesthetics | Wide variety of colors, refined matte/glossy finishes | Bright, sleek, modern finish | Diverse colors, but prone to fading and looks less premium |

Suitable Use | Most interior applications: homes, offices, hotels. | High-moisture areas (e.g., food processing plants), extreme high-impact zones. | Very low-budget projects, low-impact locations, where durability is not a priority. |

As the table shows:

- PVC trim is the most budget-friendly solution but sacrifices long-term durability and aesthetics.

- Stainless steel trim offers superior durability but comes at a higher cost with fewer color options, typically reserved for specific, demanding applications.

- Aluminum trim occupies a perfect middle ground. It provides more than sufficient durability and corrosion resistance for most interior applications and boasts a premium appearance with a wide array of colors, all at a much more reasonable price point than stainless steel. This is why aluminum trim is the most popular, cost-effective, and efficient choice for contractors and homeowners today.

Get Expert Advice and a Detailed Quote for Your Project

Choosing the right aluminum trim is a smart investment that enhances the finishing quality, increases durability, and defines the style of your entire project. A small detail, when chosen correctly, can make a significant difference in aesthetic appeal and long-term value.

We understand that every project has unique technical, design, and budgetary requirements. If you are still uncertain about which trim type, size, or color is best for you, do not hesitate to contact our team of experts. With extensive experience in finishing materials, we are ready to listen and provide in-depth consulting to help you make the optimal decision.

To receive a detailed quote for aluminum U channels or request a complete aluminum trim price list for all our product lines, contact us today. Our team will respond promptly and assist you at every stage of your project, from product selection to installation guidance, ensuring you achieve the perfect result you expect.

Frequently Asked Questions

How can I cut aluminum trim for a clean, straight edge?

For the best results, use a metal-cutting saw with a fine-toothed blade specifically designed for aluminum. Cut slowly and steadily to avoid deforming or scratching the anodized surface. Do not use a tile cutter, as it can chip the edges and ruin the trim’s finish.

Can aluminum trim be used outdoors?

Yes, but only if it has the appropriate surface finish. Aluminum trim that has been properly anodized or has a high-quality powder coat finish is weather-resistant and can be used in covered outdoor areas like balconies and patios. Avoid using trims with simple finishes, as they can oxidize or fade with direct exposure to sun and rain.

What is a suitable thickness for aluminum trim?

The required thickness depends on the application. For purely decorative uses like wall inlays, a thickness of 0.8mm to 1.0mm is sufficient. For areas that require protection and must withstand force, such as public wall corners or stair nosings, choose a thickness of 1.2mm or greater to ensure rigidity and impact resistance.

Should I use adhesive or screws to install aluminum trim?

For most decorative applications on walls and interior finishes, using a specialized construction adhesive (like high-quality silicone) is sufficient and provides the best aesthetic result by hiding all fasteners. However, for high-stress locations like anti-slip stair nosings or floor transition strips in heavy foot-traffic areas, a combination of both adhesive and screws is recommended to ensure an absolutely secure and safe installation.