In logistics, pallet selection is more than just a choice; it's a critical factor influencing efficiency and cost. Traditional wood pallets, long the industry standard, now often struggle with demands for enhanced robustness, hygiene, and efficient global transport. This brings modern stackable pallets, particularly designs like presswood, into focus as a compelling alternative. We'll explore what sets these newer pallets apart and why they frequently offer a superior solution.

What are Stackable Pallets

Stackable pallets feature bottom support structures designed to permit the safe placement of one loaded pallet directly onto another. This specific construction allows for the formation of stable, multi-tiered arrangements of goods. Such stacking is a common practice for optimizing available space within warehouses and during shipment. The orderly and dense product configurations often observed in efficient logistics operations depend on these pallets, combined with correct loading procedures.

What are Traditional Pallets

The term "traditional pallet" generally signifies the conventional wooden pallet, long utilized in supply chain operations. A common North American example is the GMA pallet, measuring 48x40 inches, a dimension standardized by the Grocery Manufacturers Association. These pallets are typically assembled using 48-inch wooden stringers that support the 40-inch top deckboards.

Stackable Pallets vs Traditional: The Main Differences

1. Design and Build

Stackable Pallet

Modern stackable pallets, such as those made from presswood, often feature a one-piece molded construction. This integrated design can result in a thinner profile and may feature a nestable design, allowing empty pallets to interlock for compact storage. The absence of nails or staples contributes to a smoother, more consistent surface.

Traditional Wood Pallet

Traditional wood pallets are typically assembled using nails or staples to join lumber components like deckboards and stringers or blocks. This method results in a structure that is generally not nestable and often has a bulkier overall profile compared to some modern alternatives.

2. Materials Used

Stackable Pallet

Modern stackable pallets are frequently manufactured from engineered wood fibers or advanced composite materials. This production method results in a pallet with consistent density and predictable structural integrity. Many such pallets are made with recycled materials, aligning with sustainability objectives. These engineered materials exhibit lower moisture absorption compared to untreated natural wood.

Traditional Wood Pallet

Traditional pallets are constructed from natural solid lumber. The inherent variability of wood means that critical properties like density, strength, and moisture content differ from one piece of timber to another. Untreated wood pallets readily absorb moisture from the environment.

3. Strength and Lifespan

Stackable Pallet

Modern stackable pallets, particularly those made from engineered materials, exhibit high structural integrity and impact resistance. Their design and material composition contribute to a prolonged operational lifespan, even under demanding industrial conditions. This inherent toughness minimizes the frequency of damage and associated downtime.

Traditional Wood Pallet

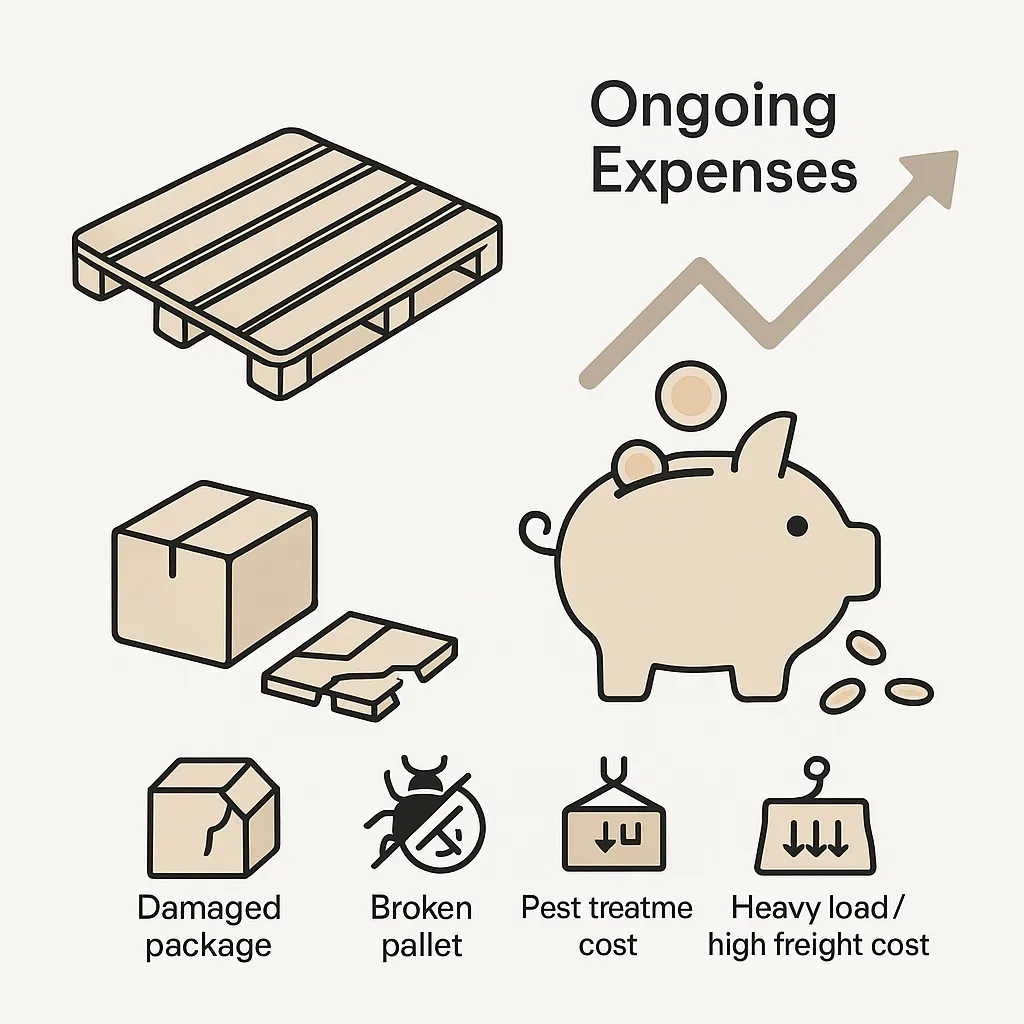

Traditional wood pallets are inherently susceptible to physical damage from handling and environmental factors. Their lifespan is often shorter compared to modern alternatives, necessitating more frequent repairs or complete replacement. Untreated wood is also vulnerable to degradation from moisture, rot, and insect attack.

4. Pest Control for Shipping

Stackable Pallet

Modern stackable pallets, especially those from engineered wood or non-wood materials, due to their material composition, meet ISPM 15 regulations for international trade. This characteristic exempts them from mandatory heat treatment or fumigation, simplifying export procedures and removing pest control burdens.

Traditional Wood Pallet

International shipment of traditional solid wood pallets necessitates specific phytosanitary treatments, such as heat treatment or fumigation, to meet ISPM 15. This procedural step adds cost to the export logistics chain and requires diligent documentation.

5. Overall Cost Value

Stackable Pallet

While some modern stackable pallets have a higher initial purchase price, their operational lifespan reveals a lower total cost of ownership (TCO). Tangible savings originate from less damage to goods, lower replacement frequencies, the absence of fumigation expenses, and improved shipping efficiency through lighter weight or superior space utilization.

Traditional Wood Pallet

Traditional wood pallets present a lower initial acquisition cost. This early saving is frequently eroded by substantial ongoing expenses from repairs, replacements due to damage, compulsory pest treatments for export, and higher freight costs attributed to their weight.

How to Use Stackable Pallets Effectively

Properly utilizing stackable pallets ensures their intended contribution to operational safety and throughput. This involves more than simply placing one unit upon another; disciplined loading, stacking, and pallet maintenance procedures, aligned with established industry practices, are required for optimal performance and longevity.

Safe Loading Practices

The stability of any stacked unit begins with how individual pallets are prepared. Distribute goods evenly across the pallet deck, avoiding concentrated loads or overhangs that can affect balance and the pallet's structural limits. Always operate within the pallet manufacturer’s specified load capacities, noting any differences between static (stationary) and dynamic (in-motion) ratings. For example, a pallet may be rated for 3,000 kg when stationary, but its dynamic capacity for movement could be 1,500 kg. Securing the goods to the pallet using stretch wrap, banding, or other unitizing methods prevents load shifting during handling and transport.

Proper Stacking Techniques

When creating multi-tiered unit loads, the supporting foundation must be sound. Ensure the floor surface or the lower pallet is level and can bear the total weight of the superimposed units. Loaded pallets should be aligned squarely to maintain vertical stability. While stacking height will vary based on product characteristics, local regulations, and handling equipment capabilities, general industry guidance, such as that from OSHA, advises maintaining stack heights that ensure stability and prevent hazards. For instance, some recommendations suggest freestanding pallet stacks should not exceed a height four times their narrowest base dimension; however, site-specific and regulatory directives always take precedence.

The nature of the goods influences the choice of stacking pattern:

Pallet Inspection and Care

A consistent inspection program underpins safe pallet operations. Before each use, visually examine pallets for any defects. Key areas to check include:

Pallets exhibiting structural defects that compromise their load-bearing ability or safe handling must be immediately removed from service. Standard industry practice requires such pallets to be either repaired following manufacturer specifications (if applicable to the pallet type and damage) or properly disposed of, considering environmental guidelines.

Upgrading to Stackable Pallets

The decision to move from traditional pallet systems to modern stackable alternatives is a strategic operational and financial choice. This transition should be guided by a clear assessment of current inefficiencies and an understanding of the specific benefits newer pallet technologies bring to a business.

When an Upgrade Makes Sense

An upgrade to modern stackable pallets is justified when specific operational challenges become persistent or demonstrably costly. For businesses with substantial international shipping, the ISPM 15 exemption of many engineered wood or non-wood pallets provides immediate relief from the expenses and logistical work associated with phytosanitary treatments for solid wood. What are the current annual costs and labor hours your operation dedicates to ISPM 15 compliance for export pallets?

If warehouse capacity optimization is a priority, certain stackable pallet designs offer quantifiable space savings. This may be through a lower operational profile allowing additional loaded tiers, or via nestable features that can reduce empty pallet storage volume by as much as 70% with some presswood designs. Could a 10-20% gain in effective warehouse cube utilization materially affect your storage expenditures or postpone facility expansion?

Furthermore, ongoing issues with product damage linked to rough pallet surfaces, protruding fasteners, or pallet structural failures are strong indicators for considering alternatives. Modern designs often feature smoother, more uniform surfaces and greater structural dependability. What percentage of your product damage or customer returns can be traced directly or indirectly to pallet-related problems, and what is the associated financial impact? Companies prioritizing sustainability will also find that pallets made from recycled materials or those offering an extended service life align with their environmental performance goals.

Planning Your Pallet Transition

A carefully planned transition minimizes operational disruptions and helps realize the full benefits of adopting a new pallet system. Key stages for planning include:

- Detailed Needs Analysis and ROI Projection: Beyond general advantages, project the return on investment using your specific operational data (e.g., anticipated reduction in product damage, lower freight expenses due to pallet weight, elimination of fumigation costs).

- Supplier Evaluation and Pallet Specification: Assess potential suppliers based on product quality, material consistency, adherence to any quality certifications, delivery reliability, and their capacity to meet your load and handling specifications. Obtain detailed technical specifications for the selected pallets.

- Pilot Program Implementation: Before a full-scale conversion, run a pilot test in a designated area or with a particular product line. This allows for practical evaluation and the identification of any unforeseen integration issues.

- Employee Training Programs: Ensure all personnel involved in material handling receive comprehensive training on the correct usage, loading, stacking, and inspection protocols for the new pallets.

- Disposition Strategy for Old Pallets: Formulate a plan for the environmentally sound disposal or recycling of the traditional pallets being phased out, consistent with your company’s environmental policies and local regulations.

Frequently Asked Questions (FAQ)

1. Are stackable pallets always more expensive upfront than traditional wood pallets?

Not necessarily always, but modern stackable pallets, especially those from engineered materials like presswood, can have a higher initial purchase price. However, it's crucial to consider the total cost of ownership (TCO), where factors like longer lifespan, reduced product damage, and no need for ISPM 15 treatments often make them more economical in the long run.

2. Can I stack any type of product on a stackable pallet?

While stackable pallets are designed for multi-tiered storage, the suitability depends on the product itself. Goods must be stable, evenly distributed, and packaged appropriately to support the weight from above. Always adhere to the pallet manufacturer's load capacity guidelines and consider product crushability before column stacking.

3. How much warehouse space can nestable stackable pallets actually save?

Nestable stackable pallets, like some presswood designs, can significantly reduce storage space for empty units. Savings can be substantial, often up to 70% compared to traditional non-nestable wood pallets, because they interlock compactly, freeing up valuable warehouse floor space.

4. Do stackable pallets require special handling equipment compared to traditional pallets?

Generally, no. Most stackable pallets are designed to be compatible with standard forklifts and pallet jacks, similar to traditional pallets. However, ensure your equipment's lifting capacity is adequate for potentially heavier or taller stacked loads, and always follow safe operating procedures.

5. If presswood stackable pallets are made from wood fibers, are they still susceptible to moisture like traditional wood pallets?

Presswood pallets are manufactured using wood fibers bonded with resin under high heat and pressure. This process results in a material with significantly lower moisture absorption (typically <8-10%) compared to untreated natural lumber used in traditional pallets, making them more resistant to moisture-related issues like mold or warping in typical warehouse environments.

6. Why is not needing ISPM 15 treatment such a big advantage for stackable pallets in international shipping?

ISPM 15 compliance for solid wood pallets requires heat treatment or fumigation to prevent pest spread, adding costs, potential delays, and administrative work for each international shipment. Engineered wood (like presswood) or non-wood stackable pallets are often exempt, streamlining customs clearance, reducing lead times, and eliminating these extra expenses.