The world of construction materials is vast, yet few options combine durability with aesthetic appeal as effectively as stainless steel's 2B finish. This finish, distinguished by its smooth and reflective surface, not only enhances the visual appeal of architectural projects but also stands as a testament to technological advancement in material science.

Whether you're a professional in the construction industry or a curious observer, the benefits of a 2B finish—ranging from its corrosion resistance to its ease of maintenance—underscore its unmatched value in both functionality and design.

As we delve deeper into the intricacies of the 2B finish, discover why this material is not just a choice but a cornerstone in modern construction and design practices.

What is 2B Finish on Stainless Steel?

The 2B finish on stainless steel is a central aspect of its application in various industries, particularly noted for its smooth, reflective surface. This finish is achieved through a cold rolling process followed by annealing and pickling, and a final light cold rolling pass. The process enhances the metal's surface, offering a smooth, moderate reflective quality that is uniform and non-directional. This characteristic makes it highly suitable for applications where aesthetics and functional utility are paramount, such as in construction, kitchen appliances, and pharmaceutical equipment.

What is a 2B surface finish standard?

The 2B surface finish standard is widely recognized and adheres to specific international guidelines, most notably defined by ASTM A480 and EN 10088. These standards detail the process and quality of the finish, ensuring a consistent, measurable characteristic of the surface across the industry. The 2B finish is known for its economic production, high corrosion resistance, and ease of cleaning. It is the most common stainless steel surface finish, used extensively in both industrial settings and food processing applications due to its chemical pickling which contributes to its smoothness and corrosion resistance.

This finish not only provides an aesthetic quality to stainless steel but also offers functional advantages, making it a preferred choice for a broad range of applications. The standardization of the 2B finish ensures quality and uniformity, essential for manufacturers and fabricators to meet the rigorous demands of their projects and products.

For detailed guidance and specifications on the 2B finish and its application, the ASTM A480 and EN 10088 standards provide comprehensive information. These documents are crucial for professionals in the field to understand the technicalities and requirements of using 2B finished stainless steel in their projects.

5 Advantages of 2B Finish Stainless Steel

Smoothness and Reflectivity

The 2B finish on stainless steel is renowned for its smooth surface and moderate reflectivity. Achieved through a meticulous process that includes cold rolling, annealing, and pickling, followed by a final light rolling, this finish ensures a uniform and non-directional surface. The inherent smoothness minimizes the accumulation of contaminants and facilitates easy cleaning, while its reflective quality contributes to the aesthetic appeal of the material in various applications.

General-Purpose Finish

As a versatile surface finish, 2B is suitable for numerous applications, balancing aesthetics with functionality. This finish is often the standard for industries where the surface requirements are not excessively demanding in terms of aesthetics. Its adaptability across different applications—from construction materials to kitchen appliances—underscores its utility as a general-purpose finish.

Cost-Effectiveness

The production process of 2B finished stainless steel is economically advantageous. The steps involved in achieving the 2B finish, while thorough, do not require the additional labor and material costs associated with more labor-intensive finishes. This cost efficiency makes 2B an attractive option for projects where budget constraints are a consideration, without compromising on quality and durability.

Suitability for Further Polishing

The 2B finish serves as an excellent base for further finishing processes. Its smooth surface can be easily polished to achieve a higher degree of reflectivity or to prepare the surface for painting or coating. This flexibility allows for customization based on the specific aesthetic or functional requirements of the project or product.

Corrosion Resistance

One of the most significant attributes of the 2B finish is its enhanced corrosion resistance. The process of annealing and pickling, integral to achieving the 2B finish, removes surface impurities and forms a chromium oxide layer that protects the steel. This chemical barrier is highly resistant to corrosion, making 2B finished stainless steel an ideal choice for environments where exposure to corrosive elements is a concern.

These advantages underscore the 2B finish's suitability for a wide range of applications, offering a balance between aesthetic appeal, functional utility, and cost efficiency. The standardization of this finish ensures consistent quality and performance, making it a reliable choice for both industrial and consumer products.

Application of 2B Finishes

Industrial and Chemical Processing

The 2B finish is widely selected for its smooth surface that facilitates easy cleaning, an essential feature for maintaining purity in harsh environments. This finish is especially beneficial in sectors where resistance to corrosion and chemical damage is necessary, such as in chemical processing equipment, pipelines, and storage tanks.

Food Processing

For food processing applications, the 2B finish offers a hygienic surface that is easy to sanitize, supporting industry standards for cleanliness. This finish ensures that surfaces do not harbor bacteria and can endure the rigors of food production environments, including exposure to acids and bases without compromising the material integrity.

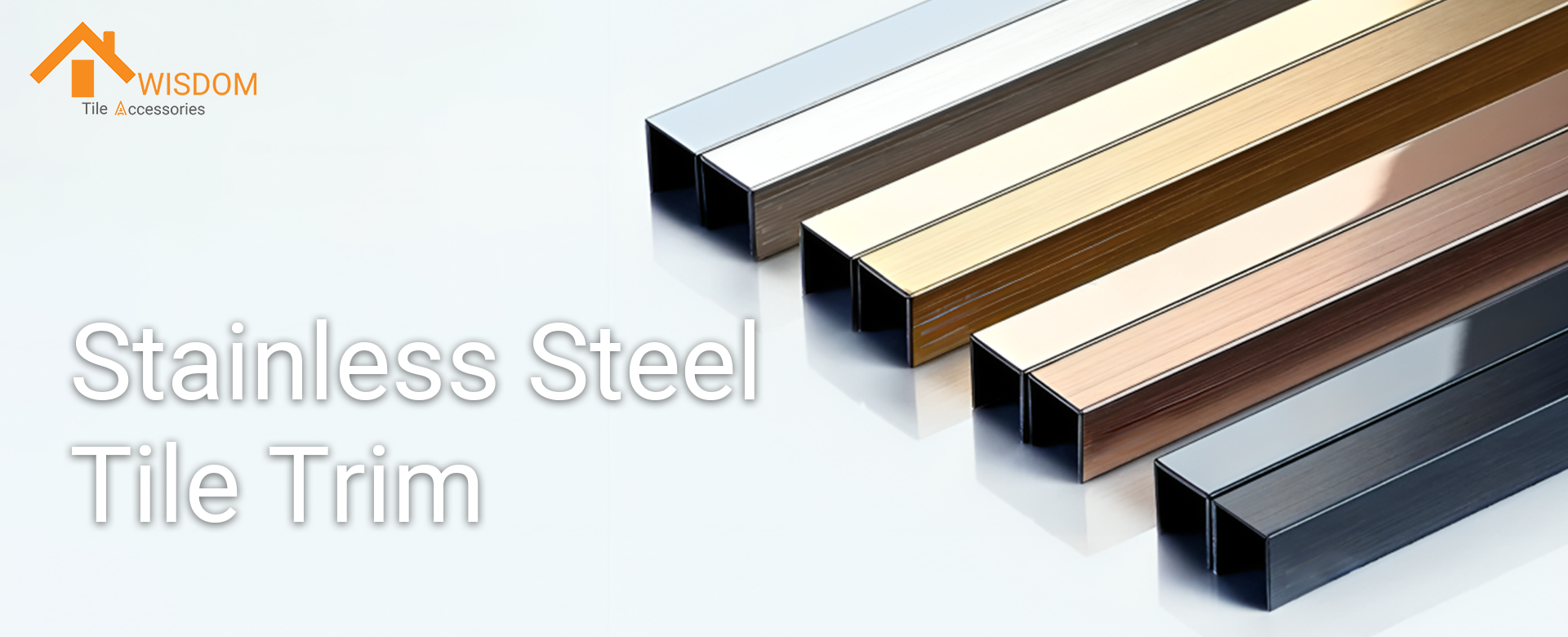

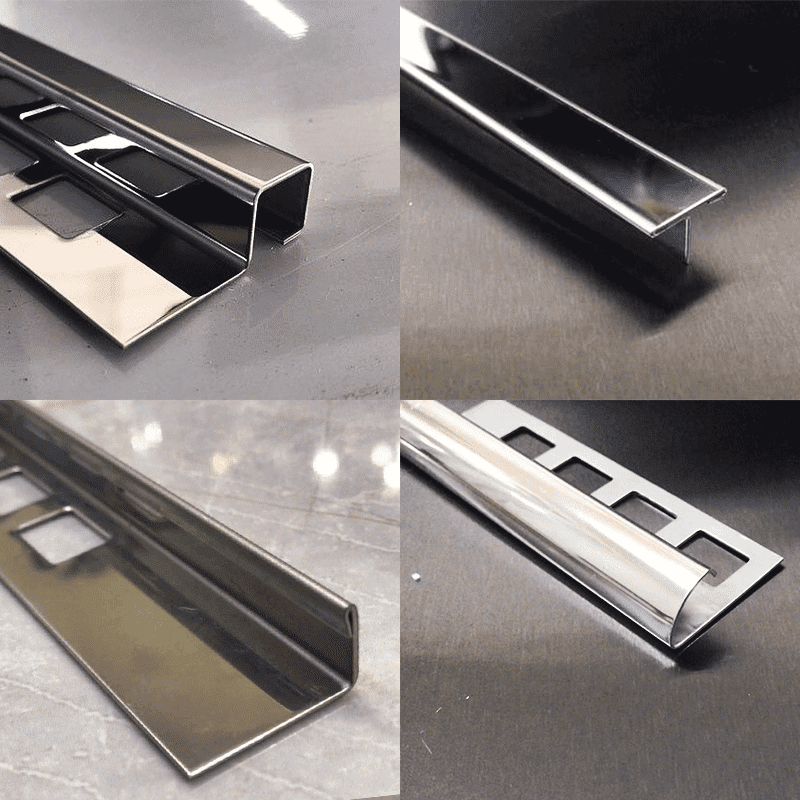

Architectural and Decorative

In architectural and decorative applications, the 2B finish lends a subtle sheen to stainless steel, making it a preferred choice for sophisticated designs. Particularly, stainless steel tile trim with a 2B finish offers a refined edge to tile installations, seamlessly integrating with modern and traditional decors. This application underscores the material's versatility, marrying aesthetic appeal with functionality. Stainless steel tile trim not only accentuates the beauty of tile work but also provides a durable solution for protecting edges and corners from wear and tear, ensuring longevity and maintaining the integrity of the design.

Medical and Pharmaceutical Equipment

The medical and pharmaceutical sectors benefit from the 2B finish due to its superior cleanliness and resistance to sterilization processes. This finish is ideal for surfaces that require regular, rigorous cleaning protocols, ensuring that medical instruments, work surfaces, and pharmaceutical manufacturing equipment remain free from contaminants.

By focusing on these applications, it becomes clear how the 2B finish on stainless steel serves diverse sectors, offering benefits that extend beyond mere aesthetics to include hygiene, durability, and ease of maintenance. The architectural application, particularly with stainless steel tile trim, showcases the material's capacity to blend functionality with design elegance, enhancing both the utility and visual appeal of spaces.

FAQ about Stainless Steel 2b Finish

What is the difference between 2B and mill finish?

The terminology around metal finishes can often be confusing, not least because of the overlap in the use of terms like "2B" and "mill finish." While both terms refer to a type of finish applied to stainless steel, they are not synonymous. The term "2B finish" specifically refers to a smooth, moderately reflective stainless steel finish resulting from a cold rolling process, followed by annealing and pickling. This finish offers a slightly reflective surface that is more about functionality than aesthetics. On the other hand, "mill finish" is a broader term that refers to the basic finish metals have as they come out of the mill. This term is not exclusive to stainless steel and can apply to aluminum, brass, and other metals. Mill finishes are characterized by their lack of polish or gloss, serving purposes where the visual appeal of the metal is not the primary concern.

What is the difference between BA and 2B finish?

When distinguishing between BA (Bright Annealed) and 2B finishes on stainless steel, the primary difference lies in the polishing process. The BA finish undergoes a process that creates a highly reflective surface, akin to approximately 400 grit polish. This finish is characterized by its mirror-like appearance, allowing for clear reflection, a stark contrast to the 2B finish which, while smooth and may have a moderate level of reflectivity, does not achieve the same mirror-like quality. In the BA finishing process, one side retains the 2B finish as the base, while the other is polished to achieve the bright, reflective quality. This dual finish offers versatility in applications, balancing functionality with aesthetic appeal.

Is 2B stainless food grade?

The 2B finish on stainless steel is indeed considered suitable for food-grade applications. This finish provides a smooth, shiny surface that can mirror objects to some extent, making it not only visually appealing but also highly functional for the food industry. Its smoothness facilitates easy cleaning and maintenance, essential properties for any material used in food preparation and processing areas. This capability to maintain hygiene, combined with the corrosion-resistant properties of stainless steel, makes the 2B finish a preferred choice. In comparison, the #4 finish, also used in the food industry, offers a matte, brushed appearance, providing an alternative where a less reflective surface is desired without compromising on hygiene and maintenance requirements.