In the world of staircase construction, few terms cause as much confusion as the stair tread and the stair nosing. This is not a minor semantic debate; it is a distinction with direct consequences for a project's safety, durability, and compliance with building codes. The tread forms the broad, horizontal surface for each step, but the nosing is what defines and protects its critical leading edge. Understanding their precise relationship is the first step toward creating a staircase that is not only built to last but is also safe for everyone who uses it, every single day.

What is a Stair Tread?

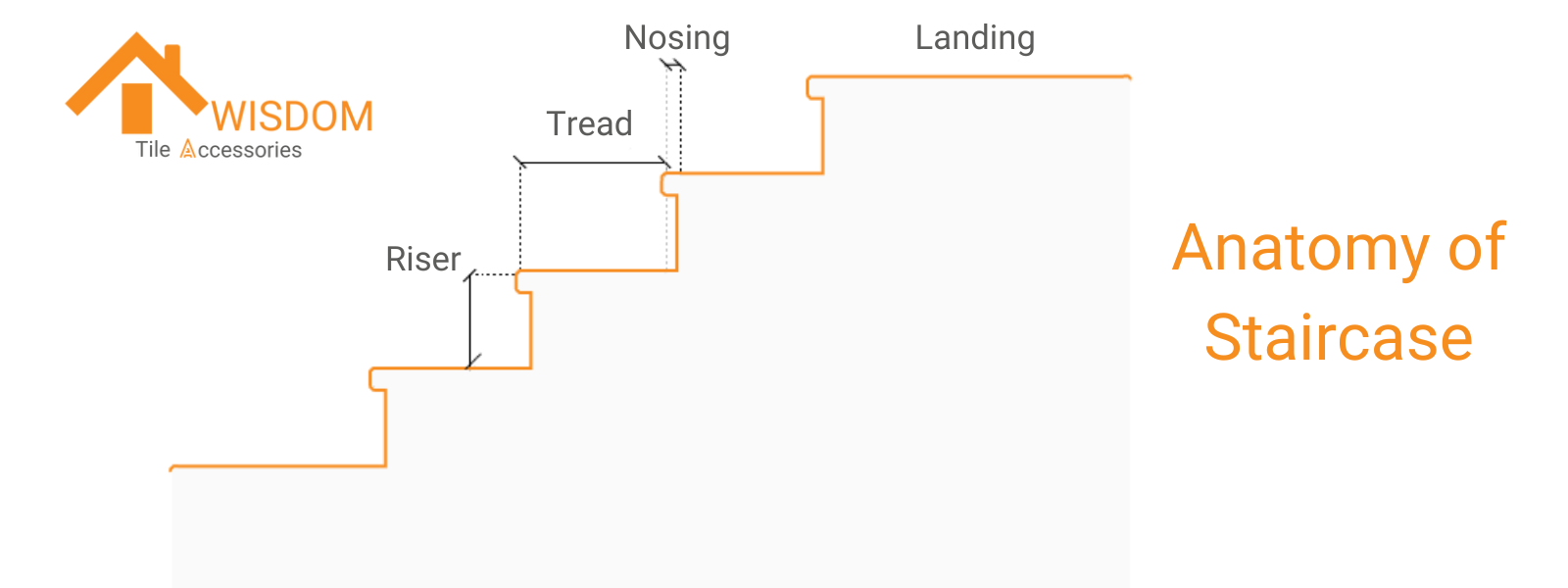

The stair tread is the horizontal, weight-bearing surface of each step. This is the platform engineered to receive your full footfall. Its front-to-back dimension, known professionally as the 'run,' directly dictates the quality of your foothold. A tread with an insufficient run forces the foot into an unstable position, turning a simple walk up or down the stairs into a precarious balancing act.

What is Stair Nosing?

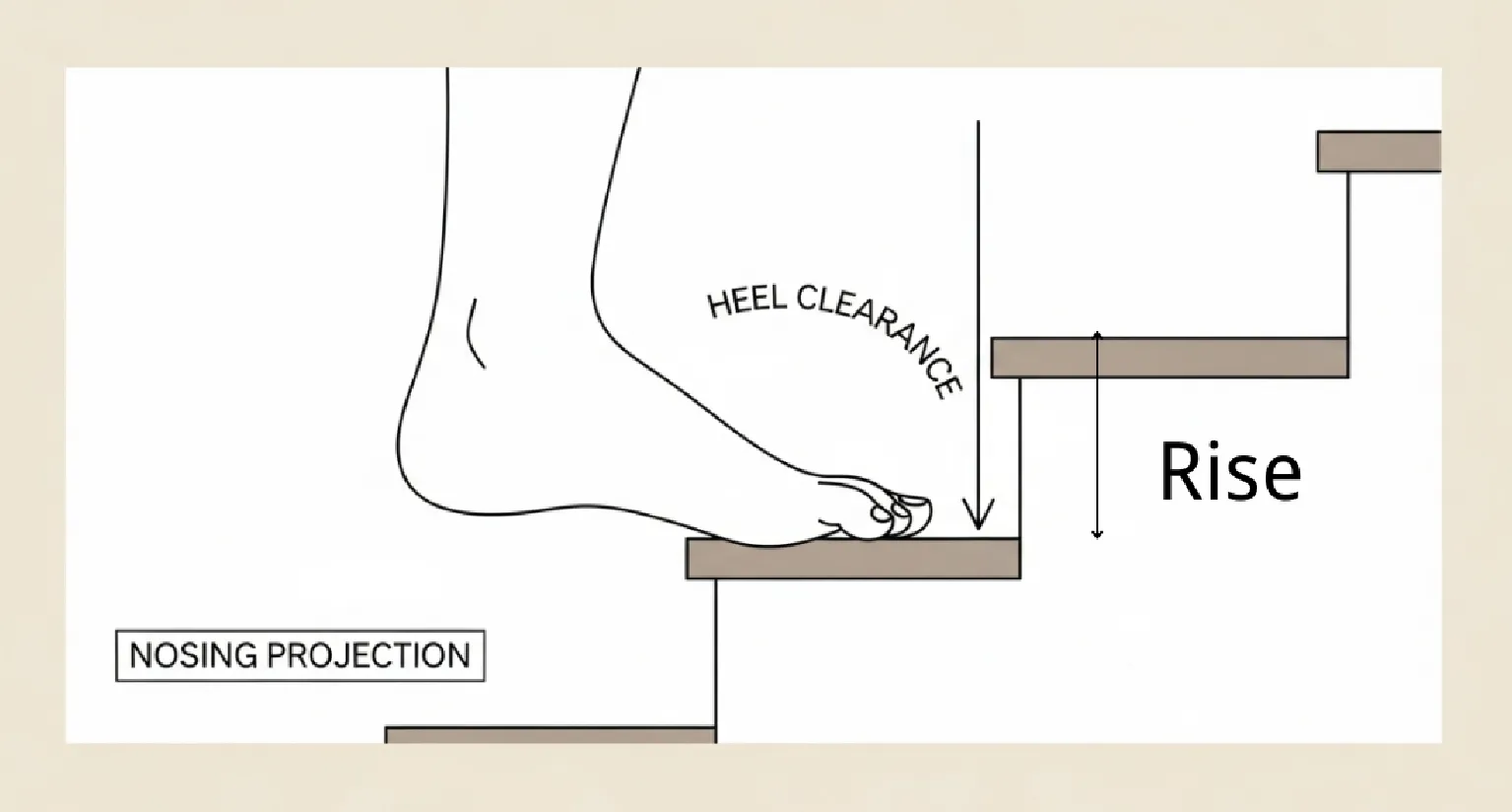

The stair nosing is the forward edge of the tread, often projecting slightly past the vertical riser below. This edge absorbs a surprising amount of punishment: the focused impact from every footstep, constant abrasion from footwear, and the occasional knock from transported items. Left unprotected, it is precisely this edge that will fail first, manifesting as splintered wood, chipped concrete, or frayed flooring.

What is the Difference Between Treads and Nosings?

The central confusion between these two terms arises because a nosing can be either a feature of a tread or a separate product installed upon it. Understanding this distinction clarifies everything.

Integral Nosing: A Built-In Feature

An integral nosing is the inherent, pre-formed front edge of a single, solid piece of tread material. Think of a traditional solid hardwood stair tread; the rounded or squared-off front edge is milled directly into the plank itself. This edge is inseparable from the tread because it is part of the same continuous material. This approach offers a seamless, monolithic appearance favored in classic construction.

Applied Nosing: A Separate Component

An applied nosing is a distinct, manufactured component that is fastened to the front of a structural stair tread or subfloor. This is the solution for modern flooring systems like Luxury Vinyl Tile (LVT), laminate, or carpeted stairs. These nosings, often made of aluminum, vinyl, or wood, are designed to overlap and protect the edge of the flooring material, creating a durable and finished transition. They are not part of the tread material but are installed onto it.

Why is Stair Nosing Important?

Beyond simple definitions, the nosing serves critical functions that are mandated by physics and often by law. Its presence or absence directly impacts the safety, lifespan, and finished quality of a staircase.

For Safety and Visibility

A person's ability to navigate stairs safely depends on clearly perceiving the edge of each step. A projecting nosing achieves this by creating a distinct shadow line, which helps the brain register depth, especially during descent.

Furthermore, building codes like the International Building Code (IBC), which governs commercial spaces, require this edge to be visually distinct. This is often accomplished with an applied nosing that features a permanent, contrasting color strip. This detail is not merely decorative; it is a non-negotiable accessibility feature for individuals with low vision.

For Durability and Protection

The nosing acts as a sacrificial shield for the most vulnerable part of the entire staircase. By capping the tread edge with a more durable material—such as extruded aluminum or dense rubber—it absorbs the impacts that would otherwise degrade the primary tread surface. This prevents the chipping of tile or concrete and the splintering of wood, dramatically extending the functional life of the stairs and reducing long-term repair costs.

For a Complete and Finished Look

Aesthetically, the nosing provides a clean, deliberate termination point for the tread. It conceals the raw, unfinished edge of a plywood subfloor or the seam where the tread material meets the riser. This single component transforms a rough-looking construction element into a polished architectural feature, resolving the visual transition between different materials and planes.

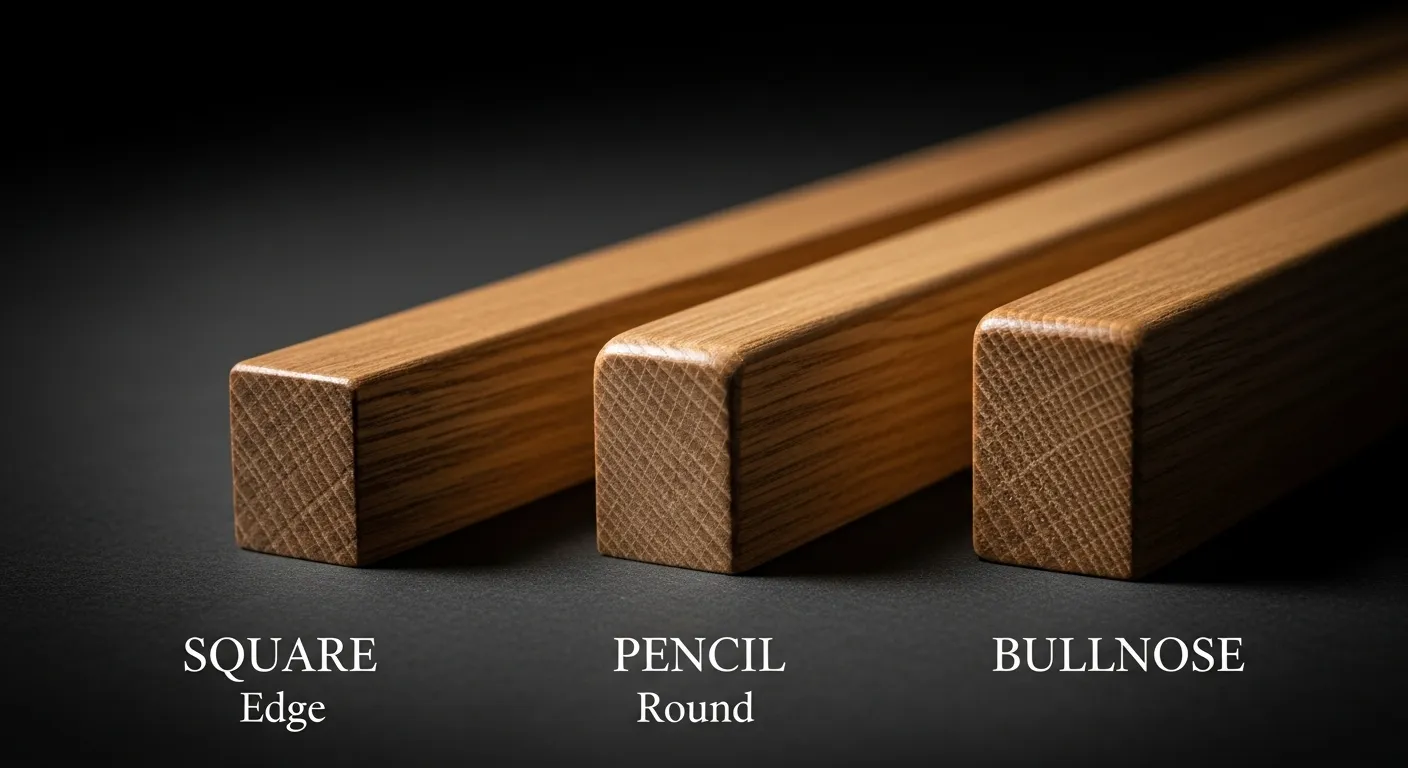

What is a Bullnose Profile?

In staircase terminology, ‘bullnose’ describes the shape of an edge, not a component itself. It refers to a distinctively soft, half-round profile, in contrast to a crisp square or minimally eased edge. This popular profile reduces the sharpness of the step edge, a feature often preferred in residential settings.

The term's ambiguity comes from its application. A bullnose profile can be an integral part of a solid wood tread, where the edge is milled into a rounded shape. Alternatively, you can purchase a separate bullnose molding, which is an applied nosing product designed with that same rounded profile to finish the edge of a laminate or LVT stair.

Expert Insight: Profile vs. Component

A common mistake is to confuse the profile (the shape, like a bullnose) with the component (the item, like an applied nosing). Remember: A solid wood tread has an integral bullnose profile. An LVT stair requires an applied nosing product, which itself might have a bullnose, square, or other profile. This distinction is the key to clear specification.

What Materials Are Used for Nosing?

The material for an applied nosing must match the demands of its environment. A quiet residential staircase and a bustling public entryway are two entirely different worlds. In the first, the goal is often aesthetic harmony. In the second, the material is chosen for raw performance.

For Residential Interiors

Here, nosings are typically selected to blend with the primary flooring, creating a cohesive design.

- Wood: A classic choice, specified to match hardwood stairs or to be painted. It provides a warm, traditional finish suitable for most interior home applications.

- Laminate & Vinyl: These are system-specific components, manufactured to create a seamless visual transition from a floor onto the staircase using the same product family.

For Commercial and High-Traffic Areas

In commercial buildings, schools, or transit stations, the calculation is different. The nosing is no longer just a finishing piece; it is a public safety device and a long-term asset. Here, materials are specified to endure relentless foot traffic and meet strict building codes.

- Aluminum: The industry standard for high-traffic areas. Its excellent strength-to-weight ratio and corrosion resistance make it ideal for framing high-traction inserts.

- Stainless Steel: Specified for environments demanding hygiene and superior corrosion resistance, such as food processing facilities, healthcare settings, and coastal areas. It combines exceptional toughness with a clean, modern aesthetic.

- Brass: Chosen for its unique aesthetic in high-end architectural and historical renovation projects. It develops a natural patina over time, adding a distinguished character while providing robust edge protection.

How to Choose the Right Nosing

Selecting the right approach to your stair nosing is not a matter of personal preference alone. It is a decision guided by your flooring system, the expected traffic, and long-term maintenance considerations.

Comparing Your Options

The choice fundamentally comes down to two systems: a solid tread with an integral nosing, or a structural tread that requires an applied nosing. The table below summarizes the practical differences.

Feature | Integral Nosing System | Applied Nosing System |

|---|---|---|

Appearance | Monolithic and seamless. The edge is part of the tread. | Can be matched or contrasted. Offers vast material & color options. |

Typical Material | Solid Wood, Precast Concrete | Aluminum, Vinyl, Rubber, Stainless Steel, Brass |

Repair | Difficult. Damage to the nose requires repairing or replacing the entire tread. | Straightforward. A damaged nosing can be unfastened and replaced independently. |

Common Use | New construction with traditional hardwood stairs. | Renovations, commercial buildings, and stairs with LVT or laminate flooring. |

Checking Building Code Requirements

Finally, the physical dimensions and profile of your nosing are regulated by building codes. Regulations like the Americans with Disabilities Act (ADA) set specific rules for how far a nosing can project and how its underside must be shaped to prevent tripping hazards. These codes are not suggestions; they are legal requirements.

Final Word of Advice

Before purchasing any materials, consult your local building department or a qualified professional. A nosing that looks good but fails inspection is a costly mistake. Confirming the local requirements for tread depth, nosing projection, and visual contrast is a mandatory step in any professional staircase project.

Clarifying Common Stair Terminology

In this business, using the right word from the start prevents confusion and costly rework down the line. Let's clear this up.

You are talking about a PRODUCT when you say:

- Stair Tread: This is the main board you walk on. When you order a "solid oak tread," you are buying the entire plank.

- Applied Nosing: This is the separate trim piece—made of aluminum, vinyl, or another material—that you buy and fasten to the edge of the stair.

You are talking about a SHAPE or PROFILE when you say:

- Bullnose: A fully rounded edge. There are no sharp corners, which is a practical benefit in any home.

- Square Edge: A crisp, 90-degree line. A good installer will slightly "ease" the corner so it is not dangerously sharp, but the look is clean and modern.

- Pencil Round: The middle ground. It is a slightly softened edge, not as fully curved as a bullnose, but not as sharp as a square profile.

You are talking about a DIMENSION or MEASUREMENT when you say:

- Run: The depth of the step from front to back. This is a critical number that must meet local building codes.

- Nosing Projection: How far the front edge of the step hangs over the vertical face of the riser below. This is also strictly regulated by code.

Knowing the difference between the part, its shape, and its measurements is not about being picky. It is about ensuring you order, install, and inspect the job correctly.

Frequently Asked Questions

What is another name for stair nosing?

In the industry, an applied stair nosing is often called 'stair edging' or 'stair trim.' While the term 'nosing' is technically correct for any tread edge, 'edging' and 'trim' almost always refer to the separate component installed during a renovation or to finish flooring like LVP.

Is the nosing included in the stair tread measurement?

This is a critical distinction for code compliance. The official tread depth, or 'run,' is measured from the face of one riser to the next and does not include the nosing projection. The nosing is the overhang. Confusing these two measurements is a common reason for failed inspections.

Can a nosing be added to existing stairs?

Yes, this is a primary purpose of 'applied nosings.' These products are specifically designed for retrofitting. They can be installed over existing structural treads—be it wood, concrete, or even properly prepared tile—to provide a new, durable, and safe edge, making them ideal for renovations.

What is the difference between a stair nosing and a 'bullnose starting step'?

A stair nosing is the edge treatment on every regular step. A 'bullnose starting step' is a unique, decorative first step of a staircase. Its sides are rounded into a semi-circle, and while this special step has a nosing, the term refers to the entire grand, introductory tread, not just its edge.