Ever noticed how rough tile edges can spoil a great design? Tile trim solves that—it protects those vulnerable spots while giving your space a sharp, finished look. In kitchens and bathrooms, where moisture and wear are constant challenges, the right trim makes all the difference. Metal options like aluminum alloy, stainless steel, and brass are hard to beat—they resist rust in damp conditions and bring a versatile look that fits any style. This guide breaks down why these materials stand out and helps you pick the right trim for your next project—visit our website to explore your options.

Understanding Tile Trim

What is Tile Trim?

Tile trim, also called tile edging or a tile border, is a slim strip that covers the exposed edges of tiled surfaces. It keeps tiles safe from chips and cracks in busy or wet areas while adding a clean, polished edge. In a bathroom vanity, it stops water from seeping into edges; on a kitchen countertop, it frames the tiles for a sturdy, neat finish.

>> See What is Tile Trim? Guide to 15 Different Types of Tile Trim

Here’s where it shines:

- Bathrooms: Guards edges around showers and vanities against moisture.

- Kitchens: Strengthens backsplashes or countertops with a sleek border.

- Living Spaces: Blends tiled floors with other surfaces seamlessly.

Materials like aluminum alloy, stainless steel, and brass are top picks, offering durability and a look that works with modern or classic designs.

Top 5 Best Materials for Tile Trim

Tile trim serves a dual purpose: it protects exposed edges and corners while providing a polished finish to tiling projects. The material you select depends on factors like installation location, budget, and desired appearance. This guide evaluates five options, emphasizing aluminum alloy, stainless steel, and brass for their durability and adaptability, followed by brief assessments of PVC and ceramic.

1. Aluminum Alloy

Aluminum alloy tile trim offers a cost-effective, lightweight solution suitable for various environments.

Pros

Cons

Best for

Key Advantages

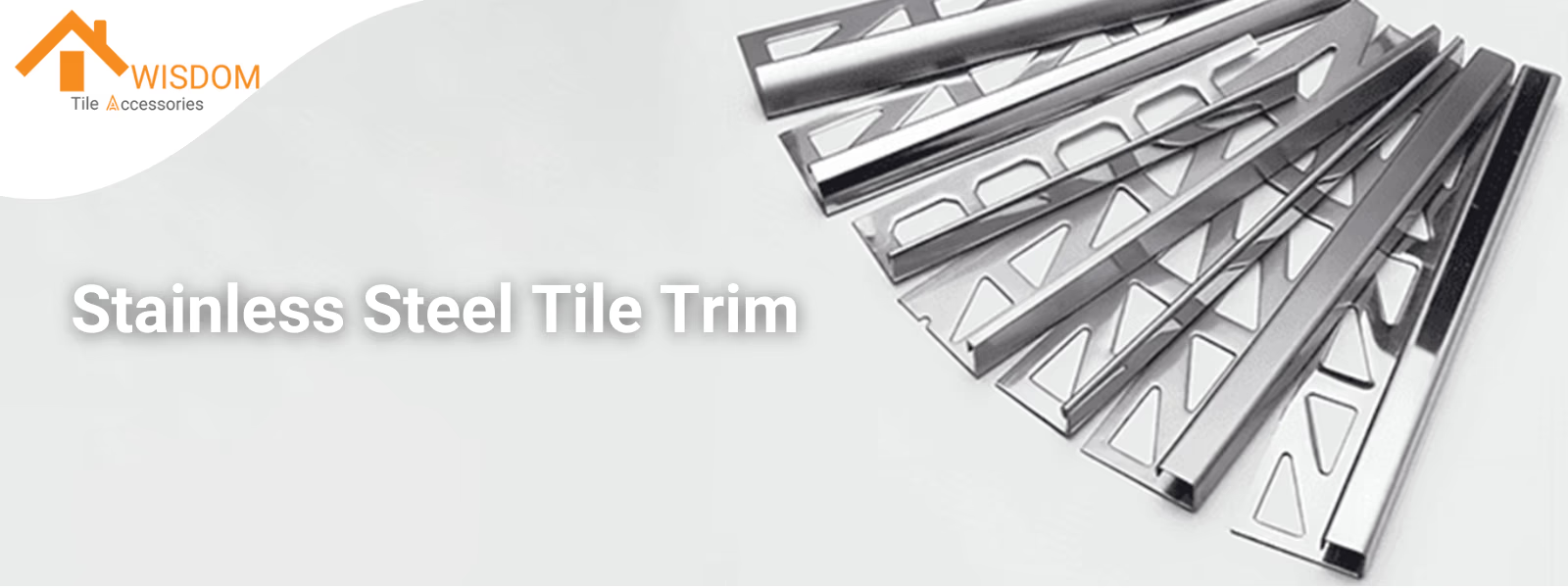

2. Stainless Steel

Stainless steel tile trim provides robust durability and a sleek finish, excelling in demanding conditions.

Pros

Cons

Best for

Key Advantages

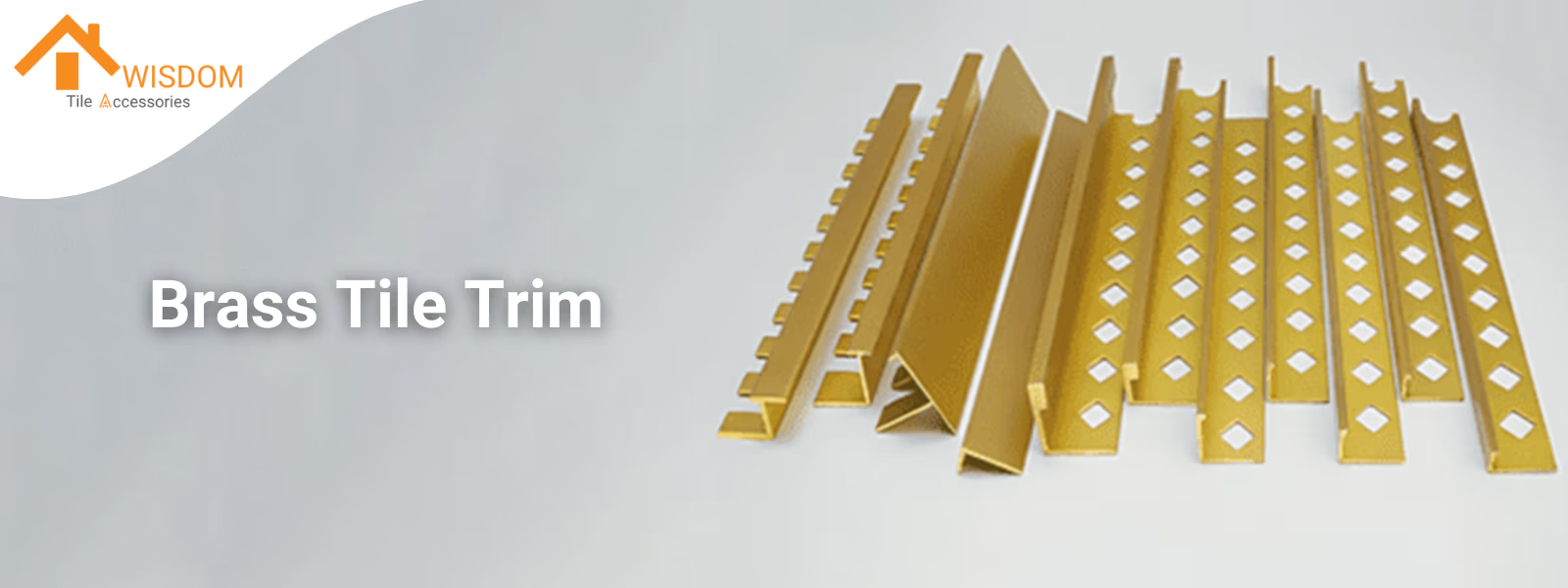

3. Brass

Brass tile trim delivers a distinctive golden hue and dependable performance, ideal for decorative applications.

Pros

Cons

Best for

Key Advantages

4. PVC

PVC tile trim is an economical choice for basic, short-term needs.

Pros

Cons

Best for

While affordable, PVC lacks the durability of metal options, making it a less versatile pick for most projects.

5. Ceramic

Ceramic tile trim integrates seamlessly with matching tiles but sacrifices toughness.

Pros

Cons

Best for

Compared to metals, ceramic is more fragile, limiting its use in active spaces.

Why Metal Trims Shine: Focus on Aluminum Alloy, Stainless Steel, and Brass

Metal trims—specifically aluminum alloy, stainless steel, and brass—offer clear benefits over PVC and ceramic in durability, appearance, and application. Stainless steel endures over 20 years in wet conditions, far exceeding PVC’s 2–5-year lifespan. Aluminum alloy resists rust in outdoor settings, unlike ceramic, which may crack in freezing temperatures. Brass withstands impacts that would fracture ceramic, maintaining integrity in busy households.

Their finishes also enhance design: aluminum alloy pairs with sleek 3x6 subway tiles, stainless steel brightens a 10x10 bathroom with reflective shine, and brass adds warmth to a 5x5 fireplace surround with natural stone. In contrast, PVC appears plain, and ceramic offers little visual distinction.

Practically, these metals adapt to diverse needs. Stainless steel manages a shower’s daily 15-minute water exposure, aluminum alloy suits a quick patio installation with porcelain tiles, and brass enhances a dining room accent wall with minimal upkeep. PVC and ceramic, however, are better suited to lighter-duty roles. Maintenance is straightforward—stainless steel and aluminum alloy need only occasional wiping, while brass requires periodic polishing to retain its look. For edges that combine longevity and style, these metals provide reliable solutions tailored to specific projects.

Comparing Aluminum Alloy, Stainless Steel, and Brass

This section analyzes the distinctions between aluminum alloy, stainless steel, and brass tile trims, focusing on their physical properties and practical applications to inform your material choice.

Aluminum Alloy vs. Stainless Steel

Aluminum alloy and stainless steel tile trims serve different purposes based on weight, cost, and resilience.

- Weight and Cost: Aluminum alloy has a density of 2.7 g/cm³, making it lighter and easier to cut than stainless steel at 7.9 g/cm³. A 10-foot aluminum strip cuts in under two minutes with a hacksaw, while stainless steel requires a power saw. Aluminum costs $1–$2 per linear foot, compared to $3–$5 for stainless steel, per standard retail pricing.

- Durability: Stainless steel trim, with a hardness of 200–300 HV (Vickers scale), resists scratches from daily use, unlike aluminum alloy, which dents under a 5-lb impact. This makes stainless steel suitable for high-traffic areas like commercial kitchens, while aluminum alloy fits residential spaces.

- Application: Aluminum alloy works well for a 10x10 patio with porcelain tiles, resisting rust in wet conditions. Stainless steel trim excels in a restaurant kitchen, enduring frequent contact without wear.

Stainless Steel vs. Brass

Stainless steel and brass tile trims differ in upkeep and visual appeal over time.

- Maintenance: Stainless steel trim needs only a damp cloth for cleaning, even after years of use, while brass requires monthly polishing in humid environments (e.g., 90% humidity near steam showers) to prevent tarnish, per metal maintenance standards.

- Appearance: Stainless steel maintains its polished finish, ideal for layouts with glass mosaic tiles. Brass develops a patina over 5–10 years, adding a greenish-brown tone that suits vintage designs like marble bathrooms with hexagonal floors.

- Application: Stainless steel trim in a shower handles 10+ gallons of daily water exposure without effort. Brass enhances a 5x5 fireplace edge, its aging finish complementing natural stone.

Brass vs. Aluminum Alloy

Brass and aluminum alloy tile trims contrast in design impact and structural strength.

- Design: Brass offers a golden tone that pairs with traditional setups, such as a Victorian kitchen with travertine tiles. Aluminum alloy’s silver finish suits layouts with white subway tiles, providing a clean, understated look.

- Strength: Brass, at 8.5 g/cm³, withstands minor impacts (e.g., a dropped glass) better than aluminum alloy, which may dent under similar force.

- Application: Brass outlines a dining room accent wall with a rich edge, while aluminum alloy finishes a kitchen backsplash economically and simply.

How to Choose the Best Metal Tile Trim for Your Project

Choosing between aluminum alloy, stainless steel, and brass tile trims requires assessing style, budget, and environmental demands. This section provides actionable guidance for your decision.

Key Considerations

Consider these factors to select the most suitable metal tile trim:

- Style Preference: Aluminum alloy complements layouts with white subway tiles or gray porcelain floors for a streamlined effect. Stainless steel trim enhances spaces with glass tiles or reflective surfaces, while brass suits setups with marble or travertine for a warm tone.

- Budget Constraints: Aluminum alloy costs $1–$2 per linear foot, stainless steel $3–$5, and brass $4–$6, per industry benchmarks. For a 20-foot edge, expect $20–$40, $60–$100, or $80–$120, respectively, affecting total project expenses.

- Environmental Needs: Stainless steel trim thrives in wet areas like showers with 80%+ humidity. Aluminum alloy resists rust on patios exposed to rain, while brass performs best in dry zones with humidity below 90%.

Scenario-Based Recommendations

Tailor your choice to specific project needs:

- Bathrooms: Stainless steel trim is optimal for its waterproof properties. In a 6x6 shower with daily use, it prevents water damage and resists scratches.

- Kitchens: Aluminum alloy provides an affordable, sleek finish. For a 10-foot backsplash with ceramic tiles, it installs easily and withstands moisture.

- Living Areas: Brass delivers a distinctive look. A 5x5 fireplace edge with natural stone benefits from its golden hue and patina over time.

Installation Tips

Ensure effective installation with these practical steps:

- Adhesives: Apply polymer-modified thin-set mortar for aluminum alloy and stainless steel trim. Use screws alongside adhesive for stainless steel on walls due to its 7.9 g/cm³ weight. Brass, at 8.5 g/cm³, may need occasional fasteners in active areas.

- Tools: Cut aluminum alloy with a hacksaw (10–12 TPI blade) in under two minutes. Use a metal-cutting blade on a power saw for stainless steel and brass to ensure clean edges.

- Fitment: Trim pieces should be 1–2 mm shorter than the tile edge to accommodate expansion, especially for aluminum alloy in outdoor settings, per tiling best practices.

Frequently Asked Questions

Which Metal Tile Trim Is Most Resistant to Moisture?

Stainless steel trim is the top choice for moisture resistance. With a corrosion resistance rating that withstands 80%+ humidity and daily water exposure (e.g., 10+ gallons in showers), per industry durability tests, it outperforms aluminum alloy and brass. Aluminum alloy resists rust in moderate conditions like patios but may pit after 10–15 years in constant wet zones. Brass tarnishes in high humidity (90%+) unless polished regularly, making it less ideal for steamy bathrooms.

How Difficult Is It to Install Metal Tile Trims Myself?

Installation difficulty varies by material. Aluminum alloy, at 2.7 g/cm³, cuts in under two minutes with a hacksaw (10–12 TPI blade) and sets with basic tile adhesive, making it beginner-friendly. Stainless steel trim (7.9 g/cm³) requires a power saw with a metal blade and screws alongside adhesive for walls, adding 10–15 minutes per 10-foot section. Brass, at 8.5 g/cm³, needs similar tools but benefits from a steady hand to avoid surface marks. With a tape measure, level, and patience, DIYers can manage all three.

Will Metal Tile Trims Discolor or Fade Over Time?

Discoloration depends on the metal and environment. Stainless steel trim retains its polished finish for 20–30 years, even in wet conditions, per longevity studies. Aluminum alloy may show slight pitting after a decade outdoors but keeps its silver tone indoors. Brass naturally shifts to a greenish-brown patina over 5–10 years, enhancing its look for some but requiring vinegar wipes (once every 6 months) to restore its original gold if preferred. Unlike PVC, none fade unnaturally.

Can Metal Tile Trims Be Used With All Tile Types?

Yes, they pair with most tiles, but compatibility matters. Stainless steel trim suits glass or porcelain tiles in showers, its strength matching their durability. Aluminum alloy works with ceramic or subway tiles in kitchens, its light weight easing alignment. Brass complements heavier stone tiles like marble or travertine in living areas, its density balancing their heft. Ensure the trim thickness (e.g., 8–12 mm) matches your tile depth for a flush finish, per standard tiling guidelines.

Conclusion

When finishing a tiling project, the material you choose for your edges matters more than you might think. Aluminum alloy, stainless steel, and brass outperform PVC and ceramic with their ability to resist moisture and wear while adding a refined look. Aluminum alloy, at $1–$2 per linear foot, protects patios and kitchens without rusting after years of exposure. Stainless steel, costing $3–$5, holds up in showers for over 20 years, keeping water damage at bay. Brass, priced at $4–$6, offers a golden edge that lasts decades in living spaces, its patina growing richer with time.

These metals bring practical benefits PVC and ceramic can’t match: longer lifespans, better impact resistance, and finishes that complement tiles like subway patterns or marble slabs. Whether you need a budget-friendly fix, a waterproof barrier, or a decorative touch, one of these options fits. To choose wisely, weigh your space’s humidity, usage, and style against each metal’s strengths. With straightforward installation—think adhesive and a hacksaw—you’ll secure edges that endure and enhance your design. Check out our selection to find a trim that works for you.