Aluminum extrusion is a widely used manufacturing process that shapes aluminum into various profiles. These profiles are integral to many industries, including construction, automotive, and electronics. By understanding the different types of aluminum extrusion profiles, manufacturers and designers can select the most suitable materials for their specific applications. This article explores the various profiles available, their creation process, and the advantages they offer.

What is Aluminum Extrusion Profiles?

Aluminum extrusion profiles are specific shapes created by forcing heated aluminum through a die. This process results in a variety of cross-sectional shapes that can be used in numerous applications. The term “aluminum profile” typically refers to these extruded forms, which have structural integrity and can be easily connected or assembled using fittings.

Aluminum extrusion profiles can be customized in terms of size, shape, and surface finish to meet specific needs. They are widely used across industries such as construction, automotive, and electronics due to their versatility and strength.

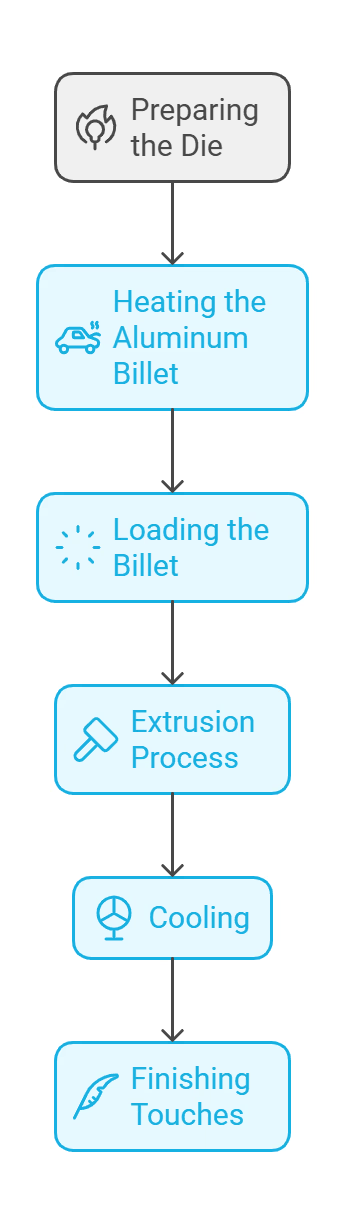

How Aluminum Profiles Are Created

Types of Aluminum Extrusion Profiles

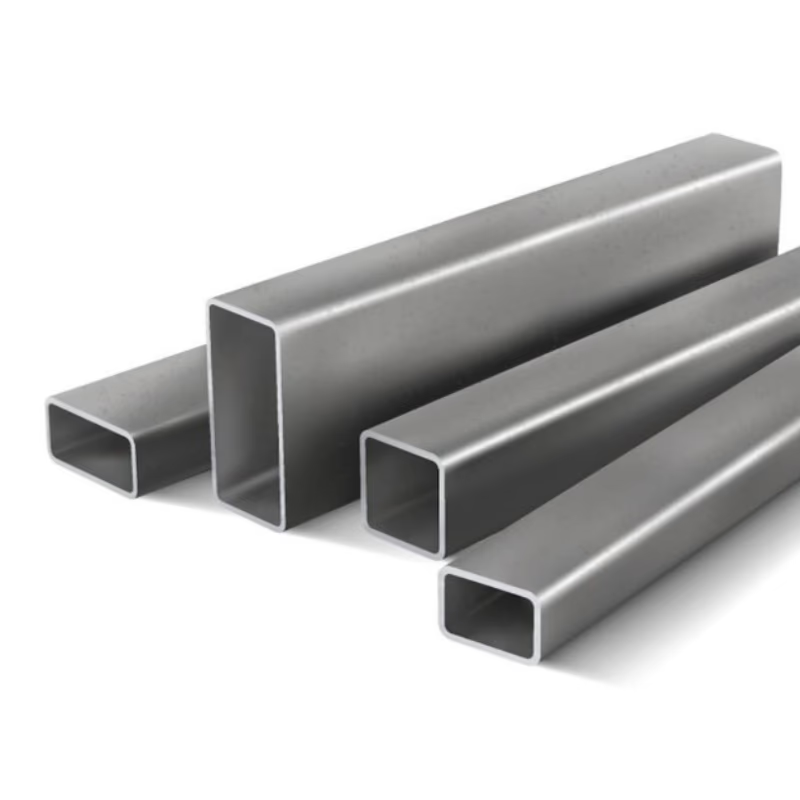

1. Hollow Beam Profiles

Hollow beam profiles are square or rectangular shapes with a hollow interior. They are used for structural support in buildings and industrial applications.

2. L-Shaped Profiles

L-shaped profiles form a 90-degree angle. They are often used for corner supports and framing in construction projects.

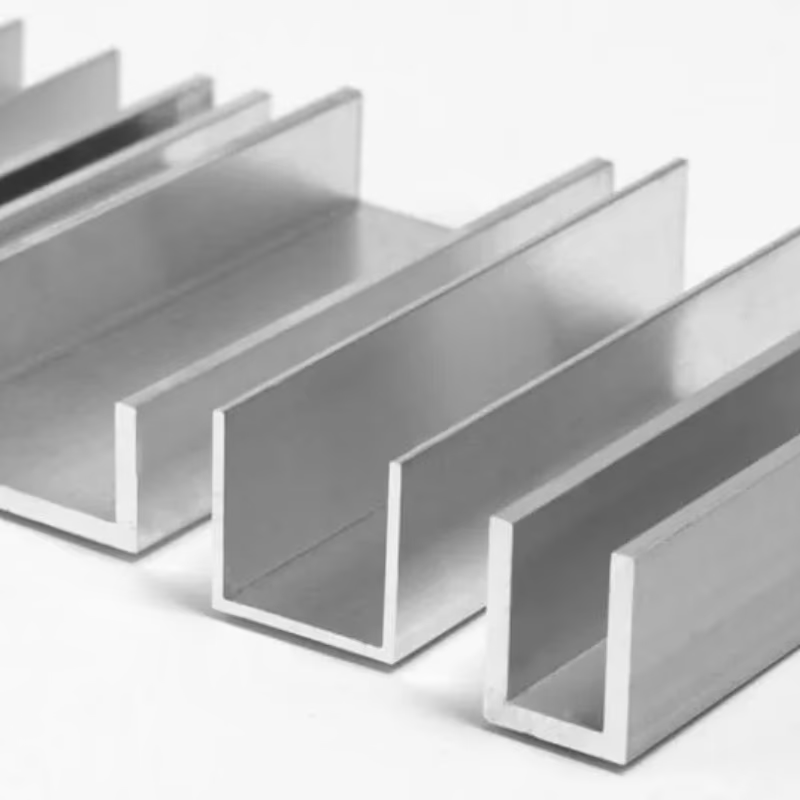

3. U-Channels

U-channels have a U shape and are used for protective covers, rims, and brackets. They provide stability in frameworks and railings.

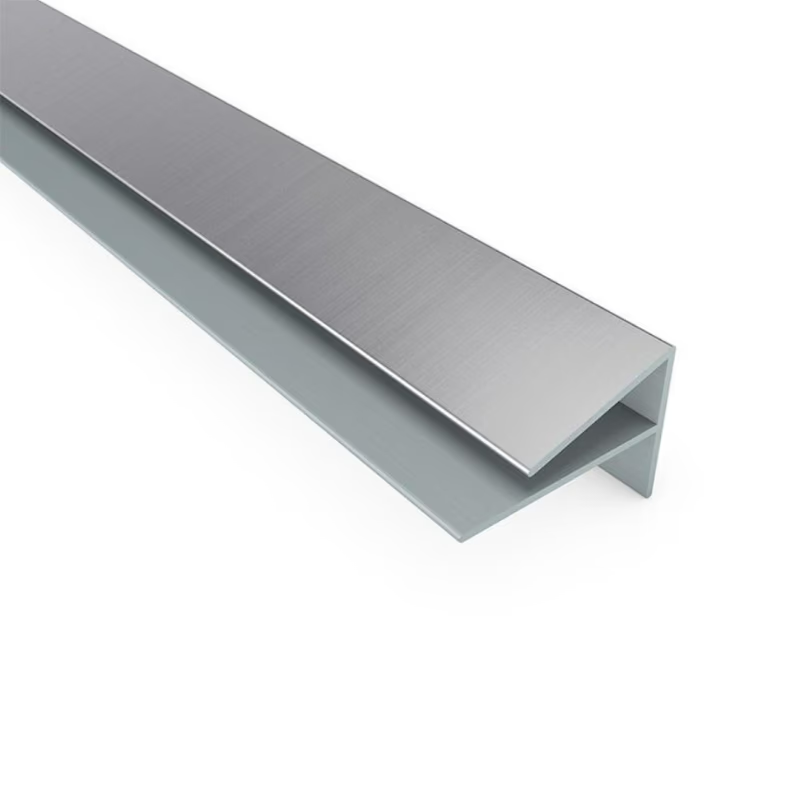

4. I-Beams

I-beams have an I shape and are common in construction. They serve as joists for floors and ceilings.

5. Triangular Profiles

Triangular profiles are used for aesthetic purposes in cabinetry and railings. They can enhance structural integrity while providing a unique design.

6. Single Radius Profiles

Single radius profiles feature a curved back with two straight edges. They are often used in window frames for weather resistance and functionality.

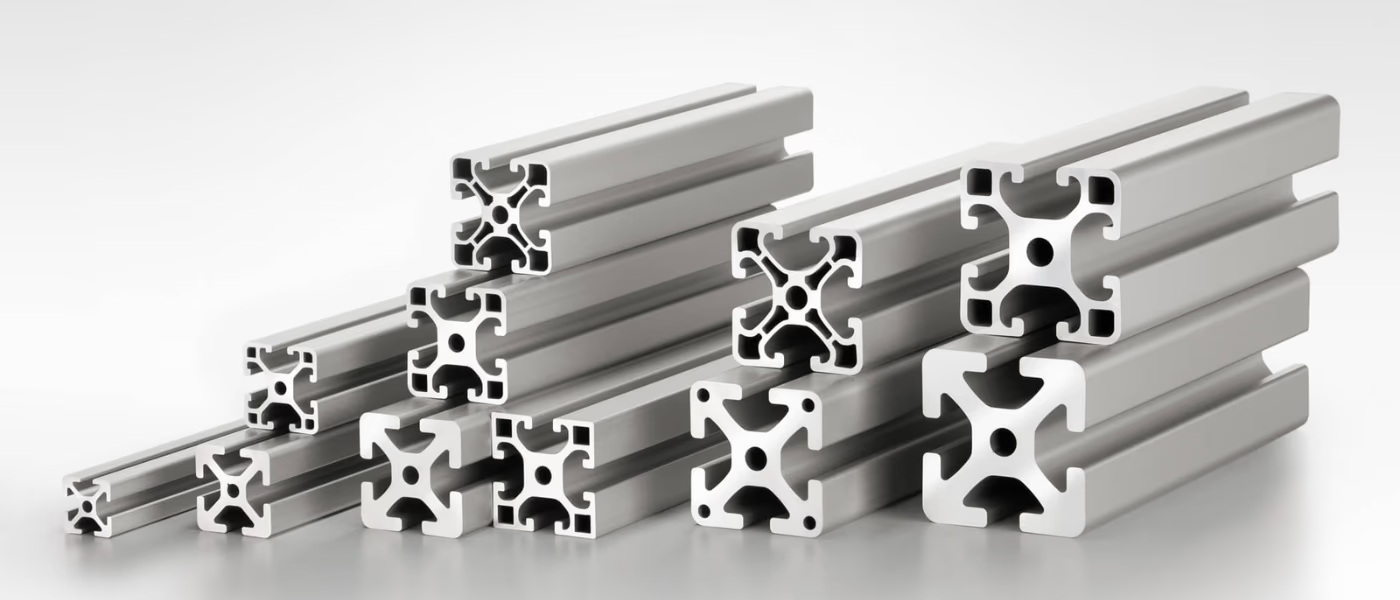

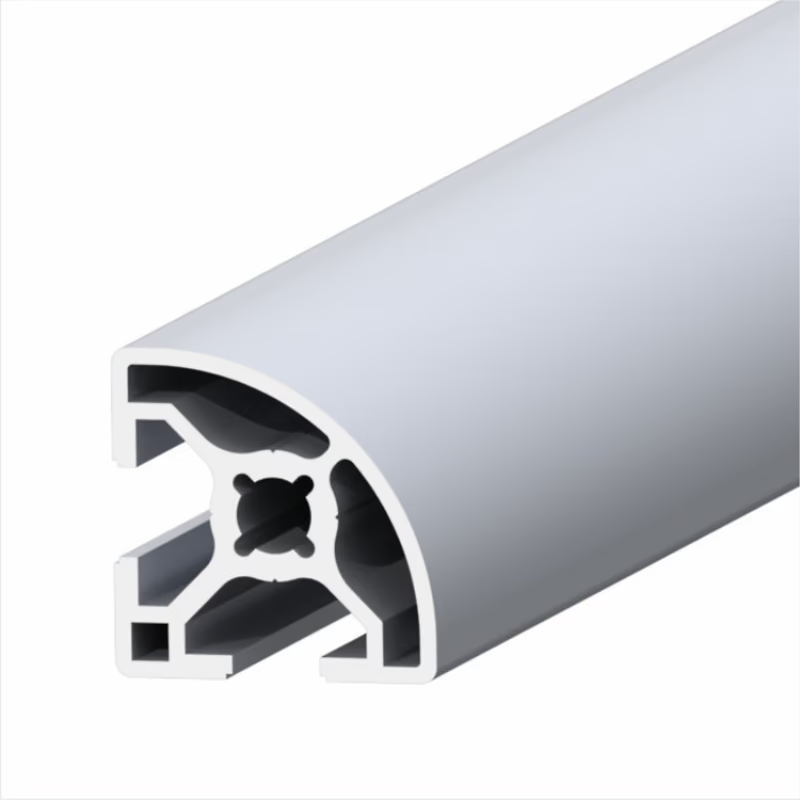

7. T-Slot Profiles

T-slot profiles allow for easy assembly of structures. They are popular in modular systems due to their compatibility with various components.

8. Flat Bar Profiles

Flat bar profiles are simple extrusions used for brackets and supports in various applications.

9. Custom Profiles

Custom aluminum extrusion profiles can be tailored to specific project needs, using different alloys and finishes.

The following are examples of aluminum profile applications:

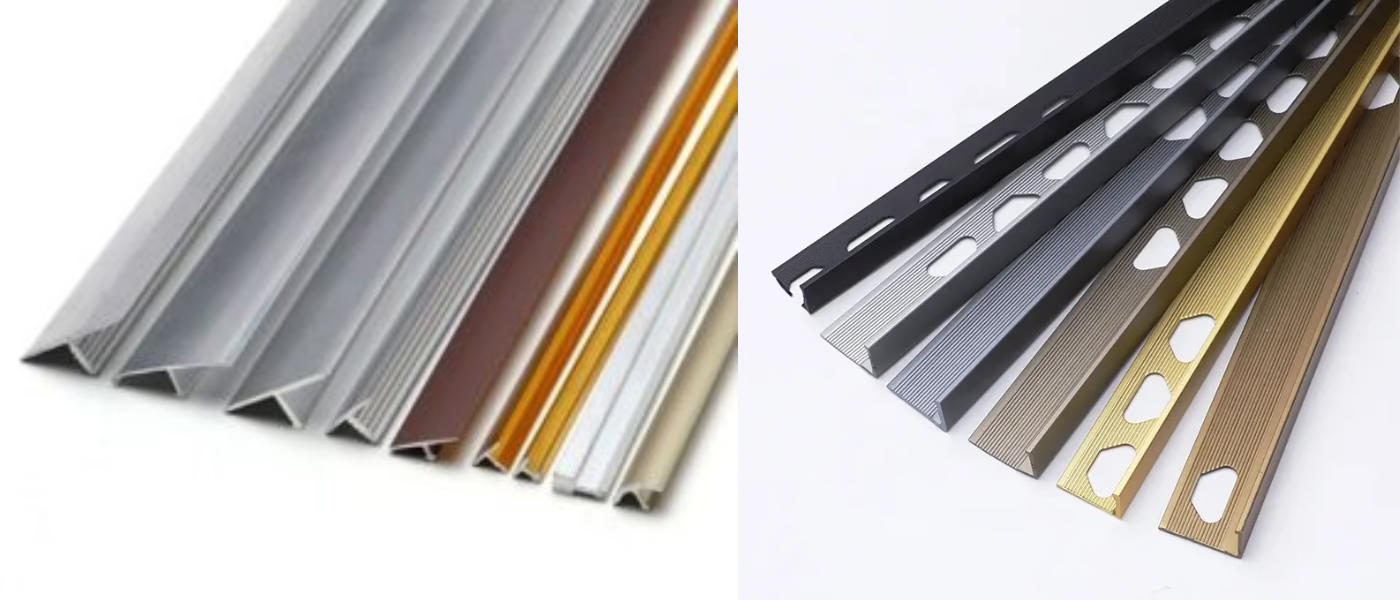

1. Tile Trim

Aluminum tile trim is used to finish edges of tiled surfaces. It protects tile edges from chipping and provides a clean look. Commonly found in bathrooms and kitchens, it enhances the overall aesthetic of tiled areas.

2. Skirting Board

Aluminum skirting boards cover the junction between the wall and floor. They provide a neat finish while protecting walls from damage. These boards are suitable for both residential and commercial spaces.

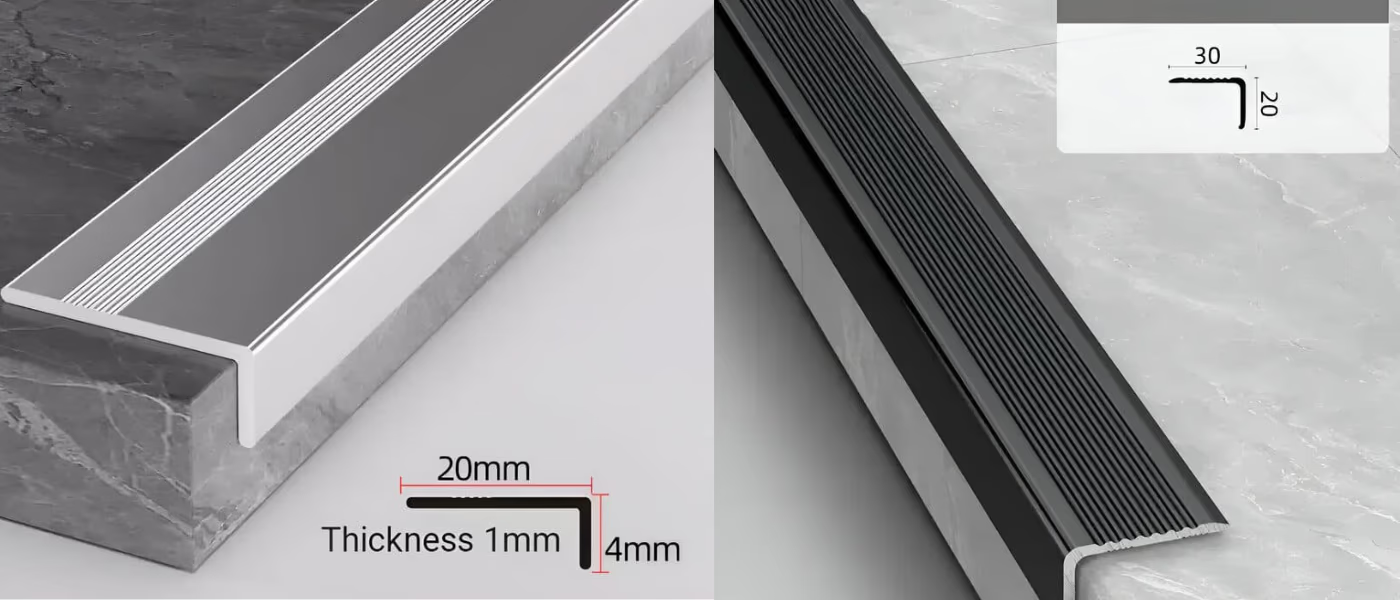

3. Stair Nosings

Aluminum stair nosings are installed on the edges of stairs to improve safety. They provide traction and visibility, reducing the risk of slips and falls. These products are commonly used in public buildings, offices, and homes.

4. Tile Transition Strips

Tile transition strips connect different types of flooring, such as tile to carpet or wood. They create a smooth transition between surfaces while protecting edges from wear. These strips are essential in residential and commercial flooring projects.

Advantages of Aluminum Profiles

FAQs about Aluminum Extrusion Profiles

1. What should I consider when choosing aluminum extrusion profiles for my project?

When selecting aluminum extrusion profiles, consider factors such as the specific application, required strength and durability, weight constraints, and design specifications. It’s also important to think about the finish and any customization options available. Additionally, consider the environmental conditions the profiles will be exposed to, as this can influence the choice of alloy and protective coatings.

2. What are the benefits of using aluminum extrusion profiles in construction?

Aluminum extrusion profiles offer several benefits in construction, including their lightweight nature, which simplifies handling and installation. They are also corrosion-resistant, durable, and can be customized into various shapes to meet specific design and structural needs.

3. What types of products commonly utilize aluminum extrusion profiles?

Aluminum extrusion profiles are commonly used in products such as window frames, door frames, railings, and structural supports. They are also found in building materials like aluminum tile trim, skirting boards, stair nosings, and tile transition strips, enhancing both functionality and aesthetics in construction projects.

4. Why should I choose aluminum extrusion profiles over other materials?

Aluminum extrusion profiles offer several advantages including lightweight properties, corrosion resistance, good strength-to-weight ratios, versatility in shapes and sizes, excellent conductivity for heat and electricity, and cost-effectiveness due to efficient production processes.

5. Can I get custom aluminum extrusion profiles for my specific project?

Yes, many manufacturers offer custom aluminum extrusion profiles tailored to meet specific project requirements. This allows you to achieve the desired dimensions and shapes while utilizing different alloys and finishes suitable for your application.