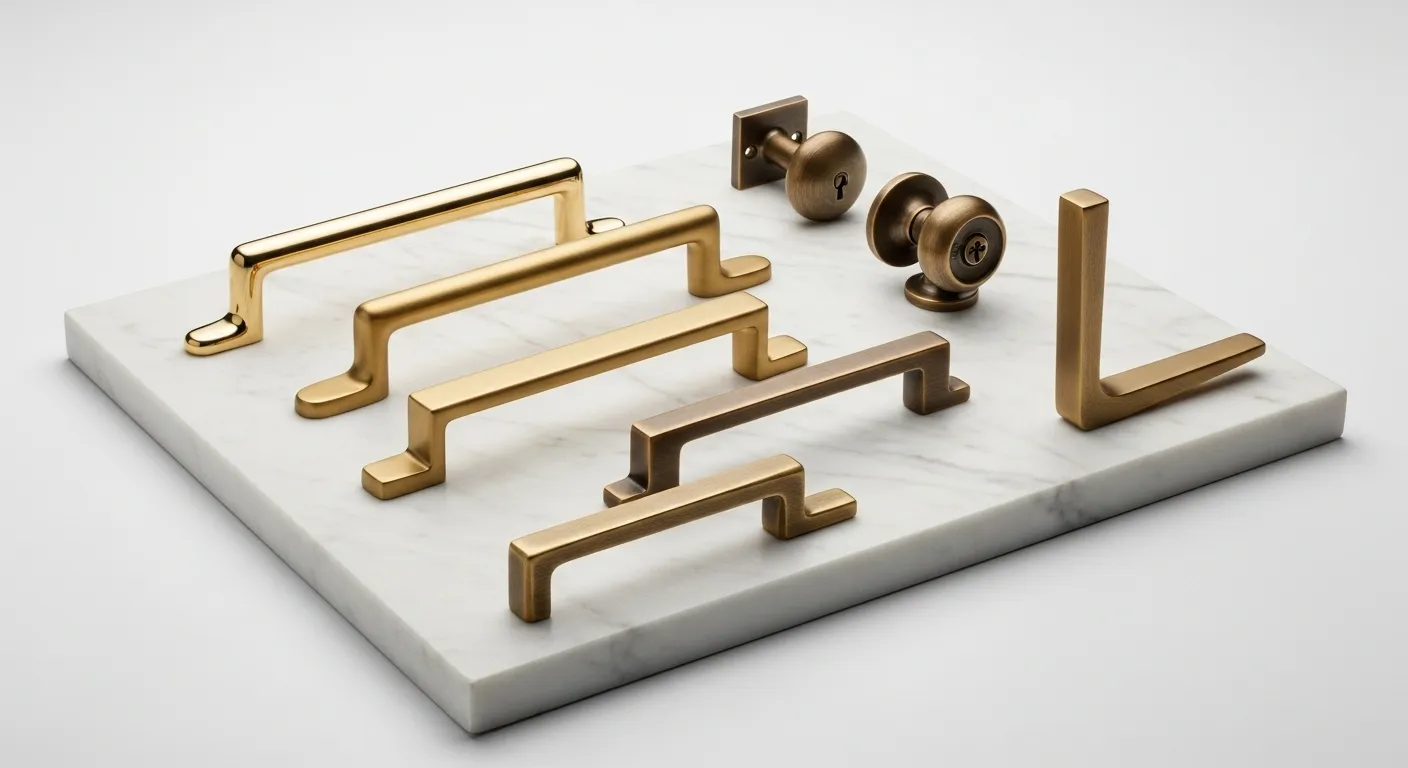

Selecting brass hardware can introduce a distinct warmth and substance to a space, yet the path to choosing the right one is often unclear. The appearance of a brass fixture on day one is only a small part of its story. How it will look after a year of use, how it responds to touch, and the maintenance it requires are determined by its finish. A successful selection depends on understanding these differences before the hardware is ever installed.

Living vs. Static Finishes: What to Know First

The initial and most consequential decision when selecting brass hardware is choosing between a "living" finish and a "static" finish. This single choice has more impact on long-term satisfaction than color or style. It is a determination between embracing the evolution of character and prioritizing unchanging consistency.

选择黄铜五金件时,最初也是最关键的决定是在“活性”饰面和“静态”饰面之间进行选择。这个单一的选择对长期满意度的影响比颜色或款式更大。它决定了是拥抱其特性的演变,还是优先考虑不变的一致性。

A living finish, such as unlacquered brass, is designed to change. It has no protective topcoat, allowing it to interact with the atmosphere and with touch. Over time, it will oxidize and develop a patina, a unique surface character that tells the story of its use. This option appeals to those who value an authentic, evolving appearance.

Conversely, a static finish is engineered to remain consistent. Finishes like lacquered brass or those created with Physical Vapor Deposition (PVD) are sealed or constructed to prevent oxidation and tarnishing. They are intended to look the same years after installation as they did on the day they were purchased, making them suitable for those who prefer predictability and minimal upkeep.

How to Judge Brass Hardware Quality

Before considering the surface treatment, the quality of the base material itself dictates the hardware's weight, feel, and ultimate lifespan.

The primary distinction lies between solid brass and brass-plated hardware. Solid brass is an alloy of copper and zinc, which is dense, strong, and naturally resistant to corrosion. Brass-plated hardware uses a less expensive base metal, such as steel or zinc, with only a thin coating of brass applied to the surface. This plating can wear away over time, especially on high-touch items, exposing the base metal beneath which can then rust or corrode.

Within solid brass products, the manufacturing method signals a further difference in quality. Forged brass is created by heating a solid billet of brass and pressing it into a die under extreme pressure. This process aligns the grain structure of the metal, resulting in a component that is substantially denser and stronger than cast brass, which is made by simply pouring molten metal into a mold.

Finally, the highest quality hardware often utilizes virgin brass, which is a pure alloy made from newly refined copper and zinc. This ensures a flawless material free of the impurities that can be found in recycled brass, allowing for a more perfect and consistent final finish.

The Magnet Test: A Simple Trick

A straightforward method to distinguish solid brass from steel-based plated hardware is to use a common magnet. A magnet will not be attracted to solid brass. If the magnet sticks firmly to the hardware, it indicates the presence of a ferrous metal like steel beneath a thin brass plating.

What Are Polished and PVD Brass Finishes

Polished brass and PVD brass both offer a bright, reflective surface, but their performance and manufacturing are fundamentally different.

The classic polished lacquered brass finish is achieved through a multi-stage process. The solid brass component is mechanically buffed with a series of progressively finer abrasives until it reaches a mirror-like sheen. To protect this surface from oxidizing, a clear protective topcoat, typically an acrylic or urethane lacquer, is applied. While this finish offers a brilliant, traditional appearance, its longevity is entirely dependent on the integrity of this lacquer. The coating is susceptible to scratches, chipping, and chemical damage. Once the lacquer is breached, air and moisture can creep underneath, causing unsightly tarnish spots that cannot be removed without stripping the entire piece.

Physical Vapor Deposition (PVD) represents the modern, high-performance alternative to lacquer. This process takes place within a vacuum chamber where the hardware is bombarded with atoms of an extremely hard material, such as Titanium Nitride or Zirconium. These particles do not simply coat the surface; they form a metallurgical bond with it. The resulting PVD brass finish can perfectly replicate the look of polished brass but offers durability on a completely different scale. It is exceptionally resistant to scratches, abrasion, and corrosion, making it virtually immune to tarnishing. This superior performance makes PVD the definitive choice for high-traffic applications like entry doors, kitchen fixtures, or any exterior hardware, especially in coastal environments.

Exploring Brushed, Satin, and Burnished Brass

Textured brass finishes provide a softer, more contemporary look compared to the high shine of polished surfaces. However, the terminology used to describe them is often a source of confusion.

A brushed brass finish is created by mechanically abrading the surface with a wire brush or abrasive belt. This process imparts a pattern of very fine, parallel lines, which diffuses light and results in a matte appearance. A protective lacquer is then typically applied to preserve the look.

The terms "brushed brass" and "satin brass" are frequently used interchangeably by retailers, but a technical difference exists. A true satin finish is achieved through a finer, non-directional process, such as blasting the surface with microscopic glass beads. This creates a smooth, velvety texture without the visible lines characteristic of a brushed finish. This smooth, low-sheen surface is superior at concealing fingerprints and water spots, making it an exceptionally practical choice for kitchens and bathrooms.

Burnished brass is a less common, artisanal finish. It is created by applying pressure to the brass surface, which smooths and hardens it rather than scratching it. This hand-rubbed process results in a deeper luster and a more organic, less uniform appearance than machine-brushed finishes.

Expert Tip: The Satin vs. Brushed Difference

While the market often conflates the two terms, a true satin finish is distinct from a brushed one. The non-directional, velvety texture of a satin finish, achieved through fine media blasting, offers superior performance in concealing fingerprints and smudges compared to the linear texture of a brushed finish.

What Is Unlacquered Brass

Unlacquered brass is solid brass in its most natural state, offered with no protective coating. This makes it a "living finish." When new, it is bright and shiny, closely resembling polished brass. However, as soon as it is exposed to the air and handled, it begins a natural aging process called patination.

Oxidation from contact with air, moisture, and the oils from human hands causes the surface to gradually darken and develop a unique character. The resulting patina can range from warm golden-browns to deeper, richer tones, creating an appearance that reflects its environment and history of use. This evolving quality is prized for adding authenticity and a sense of history to a space.

The same characteristics that define unlacquered brass are also its primary drawbacks for some users. It is highly susceptible to showing fingerprints, water spots, and stains from acidic substances. The patination process is also unpredictable. Instead of achieving the desired warm glow, the finish can sometimes settle into a dull, muddy brown appearance, which may not be aesthetically pleasing to everyone.

Understanding Antique Brass Finishes

An antique brass finish offers the appearance of aged brass in a stable, controlled form. It is not a living finish. The manufacturing process involves treating the brass with a chemical oxidizing agent to rapidly darken the surface, creating deep brown and black tones.

After this chemical aging, the piece is often highlighted by hand. The raised surfaces are lightly buffed to remove some of the dark patina, revealing the golden brass underneath. This "relieving" process adds depth and definition to the hardware. Finally, the entire component is sealed with a durable lacquer. This locks in the aged appearance and prevents any further, uncontrolled tarnishing.

This finish serves as a practical solution for those who desire a vintage look from day one without the high maintenance or unpredictable nature of unlacquered brass. A key consideration for consumers is that the exact color and darkness of antique brass can vary significantly between different manufacturers, which can make it challenging to match hardware from different sources.

Which Brass Finish Is Right For You

The ideal finish depends on a balance of aesthetic preference, location of use, and tolerance for maintenance.

Finish Type | Appearance | Durability Rating (1-5) | Maintenance Level | Fingerprint Resistance | Best For | Common Pain Point |

|---|---|---|---|---|---|---|

Polished Lacquered Brass | Mirror-like, high-gloss, bright yellow-gold | 2 | Medium | Poor | Low-traffic decorative items, formal settings | The lacquer is fragile and can chip or scratch, leading to irreversible tarnishing. |

PVD Brass | Identical to perfect polished brass, often richer | 5 | Low | Excellent | Exterior doors, coastal homes, high-traffic areas, kitchens, and baths | Higher initial cost compared to traditional finishes. |

Brushed Brass | Matte with visible, fine unidirectional lines | 3 | Low-Medium | Good | Contemporary designs, high-use areas like kitchens and family rooms | The lacquer can still fail over time, and the texture can hold grime if not cleaned. |

Satin Brass | Smooth, velvety, non-directional matte finish | 4 | Low | Excellent | Modern kitchens and baths; any area where fingerprint resistance is a priority | Market terminology is inconsistent, often confused with the less-smooth brushed finish. |

Unlacquered Brass | Starts bright and shiny, darkens to a unique patina | 3 | High (to maintain shine) / Low (to allow aging) | Poor | Heritage restorations; spaces where an authentic, evolving character is desired | Patina is unpredictable and can look messy; highly susceptible to stains. |

Antique Brass | Medium-to-dark brown with warm golden undertones | 4 | Low | Good | Traditional or vintage-inspired interiors; provides an aged look without the wait | Color and darkness can vary significantly between manufacturers, making matching difficult. |

How to Clean and Maintain Brass Finishes

Proper cleaning methods are specific to the finish type and are essential for preserving the appearance and integrity of the hardware. Using the wrong cleaner can cause permanent damage.

- Lacquered & PVD Finishes (Polished, Brushed, Satin, Antique): These static finishes are the easiest to maintain. Clean them with a soft, damp cloth and a mild solution of soap and water. Dry immediately with a clean, soft cloth to prevent water spots. It is imperative to avoid abrasive chemical cleaners, polishes (like Brasso), or scouring pads. These products will scratch and strip the protective lacquer, causing irreparable damage.

- Unlacquered Brass: The cleaning approach for unlacquered brass depends on the desired look. To allow a natural patina to develop, simply dust the hardware or wipe it with a soft, dry cloth. To restore its original shine or remove an undesirable patina, use a quality metal polish specifically formulated for brass, following the product's instructions carefully. Be aware that once polished, the patination process will begin again.

Frequently Asked Questions

What is the most durable brass finish?

The most durable brass finish available is PVD (Physical Vapor Deposition). Unlike a traditional lacquer, which is a coating applied on top of the brass, a PVD finish is metallurgically bonded to the surface in a vacuum. This creates an extremely hard layer that is highly resistant to scratches, abrasion, and corrosion, and it will not tarnish.

Can you mix different brass finishes in one room?

Yes, mixing metal finishes is a common practice in modern design. The key is to be intentional. A good guideline is to repeat each finish at least once in the space to create a sense of cohesion. For example, if you have satin brass cabinet pulls, consider matching them with a satin brass faucet. Ensure all fixtures, regardless of finish, share a similar design style (e.g., all modern or all traditional).

How can I tell if my hardware is solid brass or plated?

Use a simple magnet. Solid brass is a non-ferrous alloy and will not attract a magnet. If you place a magnet on your hardware and it sticks, the piece is likely made of a steel or iron base metal with a thin brass plating on the outside.

Will brushed brass go out of style?

While design trends evolve, brushed brass is more of a classic texture than a fleeting trend. Its matte, non-reflective surface offers a more understated and contemporary alternative to the high shine of polished brass from previous decades. It is a versatile finish that has demonstrated its staying power in a wide range of design styles.

What is the difference between brass and a gold finish?

Brass is a metal alloy composed primarily of copper and zinc, giving it a naturally warm, muted yellow tone. Gold is a precious element. In hardware, a "gold finish" is often a color description rather than a material one. It can be achieved through plating, PVD, or paint, and it typically has a brighter, more yellow hue than natural brass.

How do you restore a tarnished brass item?

Restoration depends entirely on the finish. If the item is unlacquered brass, you can remove tarnish and restore shine using a commercial brass polish and a soft cloth. If the item is lacquered brass and the tarnish is underneath the lacquer, the polish will not work. The piece must be fully stripped of its old lacquer, polished, and then re-lacquered, which is often a professional job.

What does burnished brass look like?

Burnished brass has a hand-rubbed appearance with a soft, deep luster. It is less reflective than a polished finish but often feels smoother to the touch than a brushed finish. The process involves applying pressure to smooth the metal, giving it a unique, artisanal quality that is distinct from the uniform lines of machine brushing.