The base of a wall is a zone of constant conflict. It endures scuffs from shoes, impacts from furniture, and the persistent threat of moisture from cleaning. For years, the solution has been wood or MDF skirting, materials that require a cycle of filling, sanding, and repainting. This acceptance of inevitable decay is no longer necessary. Aluminium skirting presents a permanent, engineered alternative, designed not just to cover a join but to perform flawlessly for the life of the building, ending the cycle of maintenance for good.

How Aluminium Skirting Resists Damage and Wear

The durability of aluminium skirting is not an incidental quality; it is a direct result of its material composition and manufacturing. Its ability to withstand daily abuse stems from the specific properties of the alloys used in its production.

Impacts from furniture, the abrasive action of vacuum cleaner heads, and daily foot traffic are common sources of damage for traditional skirting. Wood dents and MDF chips easily under these forces. Aluminium profiles, by contrast, are engineered to resist such impacts. The industry standard for architectural profiles is the 6063-T5 aluminium alloy. This material possesses a hardness and structural integrity that prevents the dents and deep scratches that would permanently mar softer materials.

The "T5" designation signifies a specific tempering process where the extruded profile is artificially aged in an oven. This heat treatment significantly increases the metal's yield strength, making it far more resilient. When an object strikes the surface, the force is distributed across the rigid metallic structure, preventing the localized deformation that results in a dent or gouge. This inherent toughness ensures the skirting maintains its smooth, unblemished appearance even in high-traffic corridors, commercial spaces, or active family homes.

Why Aluminium Skirting Is Impervious to Moisture

The single greatest point of failure for wood and MDF skirting is exposure to water. Aluminium resolves this issue completely due to its fundamental material properties.

Aluminium is a non-porous metal. It does not have the cellular or fibrous structure of wood-based products, so it cannot absorb water. When MDF gets wet, it acts like a sponge, swelling, deforming, and eventually disintegrating into a pulpy mass. Wood, while more resilient than MDF, will warp, swell, or rot when subjected to prolonged dampness. This makes both materials fundamentally unsuitable for areas with high humidity or where water contact is likely.

In contrast, aluminium is dimensionally stable. It remains entirely unaffected by moisture, steam, or direct water contact. This makes it the definitive solution for kitchens, bathrooms, laundry rooms, and basements. Where wood or MDF would inevitably fail, aluminium provides a permanent installation. Furthermore, because it is an inorganic material, it cannot support the growth of mold or mildew. This is a critical advantage in maintaining a hygienic indoor environment, preventing the health risks associated with fungal growth behind and within the skirting.

The End of Repainting and Tedious Maintenance

A primary frustration for property owners is the constant upkeep required to keep painted skirting looking clean. Scuffs, chips, and fading necessitate a recurring cycle of sanding, filling, and repainting. Aluminium skirting eliminates this entire maintenance burden.

The color and surface of an aluminium profile are not achieved with site-applied paint. Instead, they are created through advanced factory finishing processes like anodizing or powder coating. These finishes are bonded to the metal on a molecular or thermal level, creating a surface that is far harder and more resilient than any liquid paint.

This bonded finish will not peel, flake, or chip under the stresses of daily life. Where a painted surface would be damaged, an aluminium finish resists the abrasion. Most scuffs and dirt marks do not penetrate the finish and can be wiped clean with a damp cloth without any damage to the surface. This simple cleanability transforms skirting from a high-maintenance element into a component that requires no more attention than a window frame or a door handle. It is a fit-and-forget solution that frees property owners from the time and expense of perpetual touch-ups.

Is Aluminium Skirting an Eco Friendly Choice

In modern construction, material selection is increasingly guided by environmental impact. Aluminium presents a strong case as a sustainable building material, particularly when compared to the alternatives.

The most significant environmental benefit of aluminium is its recyclability. Aluminium is 100% recyclable, and it can be melted down and reformed into new products indefinitely without any loss of its physical or chemical qualities. This creates a closed-loop lifecycle. The energy required to recycle aluminium is approximately 5% of the energy needed to produce primary aluminium from bauxite ore.

Consequently, many architectural aluminium profiles are manufactured with a high percentage of recycled content. Choosing aluminium skirting helps reduce the demand for virgin resources and lowers the overall carbon footprint of a building project. It also lessens the reliance on timber resources, which can contribute to deforestation if not sourced from verifiably sustainable forests. Its long lifespan further enhances its green credentials, as it eliminates the waste generated by the frequent replacement of less durable materials.

What Makes Aluminium Skirting So Strong

The strength of aluminium skirting comes from a combination of the raw material and the manufacturing method used to shape it. The process, known as extrusion, allows for the creation of profiles that are both strong and lightweight.

Extrusion begins with a solid cylindrical log of aluminium alloy, called a billet. This billet is heated in a furnace until it becomes malleable but is still in a solid state. A powerful hydraulic ram then forces the softened metal through a hardened steel die, which is a cross-sectional template of the desired skirting profile. The aluminium emerges from the die as a long, continuous piece with a precise and uniform shape.

The alloy most commonly used, 6063-T5, is specifically chosen for its excellent combination of strength and surface finish quality. The extrusion process itself contributes to the material's strength by refining its grain structure. This method allows for the design of complex profiles with internal support structures and hollow chambers, features that add rigidity without adding significant weight. This is a distinct advantage over wood, which is a solid, heavy material, and MDF, which lacks structural integrity.

Anodized vs Powder Coated Aluminium Skirting

The final finish on aluminium skirting not only determines its color and appearance but also adds a significant layer of protection. The two premier finishing technologies are anodizing and powder coating. The selection between them depends on the specific aesthetic requirements and the environmental conditions of the installation.

Anodizing is an electrochemical process that thickens and hardens the natural protective oxide layer on the surface of the aluminium. The resulting finish is integral to the metal itself, meaning it cannot peel or flake. It is exceptionally hard and abrasion-resistant, making it a superior choice for high-traffic commercial areas.

Powder coating involves applying a dry, powdered pigment and resin mixture to the profile using an electrostatic charge. The profile is then baked in an oven, where the powder melts and cures into a hard, paint-like shell. The primary advantage of powder coating is its color versatility, offering a virtually unlimited palette to match any design scheme.

Attribute | Anodizing | Powder Coating |

|---|---|---|

Process | An electrochemical process that makes the finish an integral part of the metal. | Electrostatically applied resin powder is oven-cured to form a hard shell on the surface. |

Durability | Extremely hard and abrasion-resistant. Superior for high-traffic areas. | Very durable and resistant to chipping, but softer than an anodized finish. |

Appearance | Provides a deep, translucent metallic sheen. The underlying metal grain can be visible. | An opaque, uniform finish available in various gloss levels (matte, semi-gloss, high gloss). |

Color Options | Limited to a palette achievable through the process, such as silver, black, and bronze. | Virtually unlimited color selection, often matched to any RAL code for precise design coordination. |

UV Resistance | Excellent. The color is highly stable and will not fade, even in direct sunlight. | High-quality formulations offer very good UV resistance, but all organic coatings can fade over time. |

Chemical Resistance | Can be damaged by highly acidic or alkaline cleaning agents. | Generally more resistant to a wider range of chemicals, solvents, and harsh cleaners. |

Best Use Cases | High-traffic commercial corridors, public spaces, and applications where maximum abrasion resistance is needed. | Projects requiring specific custom colors, most residential applications, and areas where chemical cleaning is expected. |

Aluminium Skirting vs Wood and MDF

A direct comparison with traditional materials highlights the long-term value of aluminium. While initial price is a factor, a true assessment must consider durability, maintenance costs, and lifespan, which collectively determine the total cost of ownership.

The Problem of Material-Environment Mismatch

A core reason for the failure of traditional skirting is a mismatch between the material and its environment. Materials like MDF and wood perform adequately in perfectly dry, stable conditions but are guaranteed to fail when placed in areas they are not suited for, such as bathrooms or basements. This mismatch creates a predictable point of failure. Aluminium, by contrast, is a universal solution. Its inherent properties make it suitable for every interior zone, eliminating the risk of premature failure due to an environmental mismatch.

The following table evaluates the materials across the most critical performance criteria, demonstrating why a higher initial investment in aluminium often results in significant long-term savings.

Criteria | Aluminium | Solid Wood | MDF (Medium-Density Fibreboard) |

|---|---|---|---|

Impact Resistance | Excellent. High-strength alloy resists dents and scratches. | Good. Hardwoods are durable; softwoods can dent easily. | Poor. Very susceptible to chipping and denting from minor impacts. |

Moisture Resistance | Exceptional. Completely waterproof. Will not rot, warp, or swell. | Poor. Absorbs moisture, leading to warping, swelling, and rot. | Very Poor. Acts like a sponge, swelling and disintegrating rapidly when wet. |

Pest Resistance | Exceptional. Impervious to termites and other wood-boring insects. | Poor. Vulnerable to termite infestation and damage. | Poor. Can be damaged by pests, especially if moisture is present. |

Maintenance | Minimal. Requires only occasional wiping. No repainting is ever needed. | High. Requires periodic repainting or re-staining to maintain appearance. | High. Requires frequent touch-ups for chips. Moisture damage necessitates replacement. |

Lifespan | Very Long. Designed to last for the life of the building with minimal degradation. | Moderate to Long. Lifespan is highly dependent on maintenance and environment. | Short to Moderate. Easily damaged, often requiring replacement within a few years. |

Initial Cost | Moderate. Higher than MDF, comparable to or less than premium hardwoods. | Moderate to High. Pine is affordable; hardwoods are a premium option. | Low. The most budget-friendly option for initial purchase. |

Lifetime Value | Excellent. Zero maintenance costs and extreme longevity provide superior long-term value. | Fair. Ongoing maintenance and potential replacement costs reduce its lifetime value. | Poor. Low durability and short lifespan often lead to higher costs over time. |

Concealing Wires with Integrated Cable Channels

The modern interior is filled with low-voltage wiring for internet, speakers, and other electronics, often creating unsightly clutter. Aluminium skirting provides a clean and integrated solution to this problem.

The extrusion process makes it possible to design profiles with hollow internal chambers. These channels act as a concealed duct, allowing data, telephone, and audiovisual cables to be run discreetly around the perimeter of a room, completely hidden from view. This creates a tidy, organized interior free of tangled wires.

Many advanced systems feature a two-part design with a removable front cover. This allows for easy access to the wiring at any time in the future. If a new cable needs to be added or an old one removed, the cover can be simply snapped off and replaced without disturbing the wall or the installation. This transforms the skirting from a decorative trim into a functional part of the building's data infrastructure.

Creating Ambiance with LED Skirting Lights

Integrated lighting is one of the most innovative applications for aluminium skirting, adding both atmosphere and practical illumination to a space.

Specialized profiles are extruded with a dedicated channel designed to house flexible LED strip lighting. This channel is often paired with a snap-in polycarbonate diffuser, which protects the LEDs and softens the light to produce an even, continuous glow. This feature serves a dual function.

From a design perspective, it can be used to create striking visual effects. The light can wash up the wall to create a "floating" illusion, provide a subtle accent, or add a layer of warmth to a room's ambiance. From a practical standpoint, it serves as effective and energy-efficient pathway lighting. In hallways, on stairs, or in home cinemas, it provides safe, low-level illumination for navigating in the dark.

Achieving a Flush Look with Shadowline Profiles

For designers and architects pursuing a highly minimalist interior, the protrusion of a traditional skirting board can disrupt the clean plane of a wall. Aluminium offers a sophisticated solution with recessed or "shadowline" profiles.

These systems are designed to be installed so that the face of the skirting sits perfectly flush with the finished wall surface. A small, crisp recess or "shadow line" is created between the top of the skirting and the wall, forming a deliberate architectural detail. This technique eliminates the visual interruption of a projecting baseboard, allowing the wall to flow cleanly and uninterrupted to the floor. The result is a sharp, precise, and uncluttered look that is highly valued in contemporary architecture.

>> See What is Shadow Gap Profiles

How to Select High Quality Aluminium Skirting

Not all aluminium skirting products are of the same quality. To ensure you are purchasing a product that will deliver on its promises of durability and performance, it is important to evaluate it against several key criteria.

- Confirm the Alloy and Temper. A reputable manufacturer will specify the material used. Look for the 6063-T5 alloy, which is the industry standard for architectural quality, ensuring the right balance of strength and finish.

- Inspect the Finish. Whether anodized or powder-coated, the finish should be uniform and free of defects. For powder coating, ask if a pre-treatment process was used, as this enhances corrosion resistance. For anodizing, a thicker coating provides a longer life.

- Demand a Complete System. A high-quality product line includes a full range of matching accessories. Check for the availability of pre-formed internal and external corners, connectors, and end caps. These components eliminate the need for difficult on-site miter cuts and ensure a professional, seamless installation.

- Review the Warranty. A manufacturer's warranty is a statement of confidence in their product. Look for a comprehensive warranty of at least 5-10 years that covers defects in both the material and the finish.

- Assess the Range of Options. A dedicated manufacturer will offer a wide selection of profiles, heights, and finishes. A broad and well-designed product range is often an indicator of a company with deep industry expertise.

Frequently Asked Questions

What are the disadvantages of aluminium skirting?

The primary disadvantages are a higher initial purchase price compared to MDF and the potential for scratching under heavy, sharp impacts, although it is far more resistant than wood or paint. Some may also find the metallic sound it makes if struck to be a drawback in certain quiet environments.

Is aluminium skirting expensive?

Aluminium skirting has a higher upfront cost than MDF or PVC. However, it should be viewed as a long-term investment. When factoring in its zero-maintenance requirements (no repainting) and extremely long lifespan, its total cost of ownership is often lower than that of cheaper materials that require regular repair and replacement.

Can you install aluminium skirting yourself?

Yes, many aluminium skirting systems are designed for straightforward installation. Systems that use mounting clips or direct-stick adhesive are particularly DIY-friendly. Cutting profiles to length requires the correct tools, typically a mitre saw equipped with a blade designed for non-ferrous metals, to ensure clean, precise cuts.

Can aluminium skirting be painted?

While it is technically possible to paint aluminium after applying a specialized metal primer, it is not recommended. Doing so negates one of its primary benefits: the extremely durable, maintenance-free factory finish. A site-applied paint will never be as resilient as an anodized or powder-coated surface.

How do you clean aluminium skirting boards?

Cleaning is simple. For general dust and dirt, wipe the surface with a soft, damp cloth. For more stubborn marks, a mild detergent mixed with water can be used. It is important to avoid abrasive cleaners, scouring pads, or harsh chemicals, as these can damage the finish.

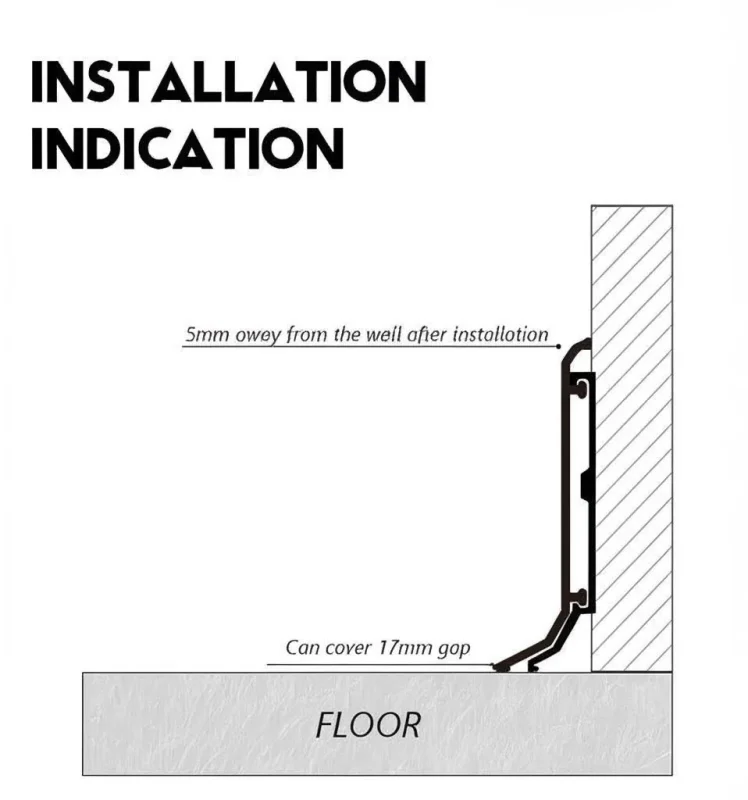

Does aluminium skirting work with all floor types?

Yes, aluminium skirting is compatible with all floor types, including carpet, tile, timber, vinyl, and laminate. It is particularly useful with floating floors like laminate or engineered wood, as it can effectively cover the mandatory expansion gap left around the perimeter of the room.

What sizes and colors are available?

Aluminium skirting is available in a wide range of sizes, with common heights including 60mm, 80mm, and 100mm. Color options are extensive. Anodized finishes typically come in metallic shades like silver, black, and bronze. Powder-coated finishes can be produced in virtually any color from the RAL color system, allowing for perfect coordination with any interior palette.