Are you questioning the necessity and functions of uncoupling membranes in tile installation? This article dives deep into what is uncoupling membrane and why it is indispensable. Whether you are a builder or tile installer, let’s understand and learn the best practices for uncoupling membrane installation.

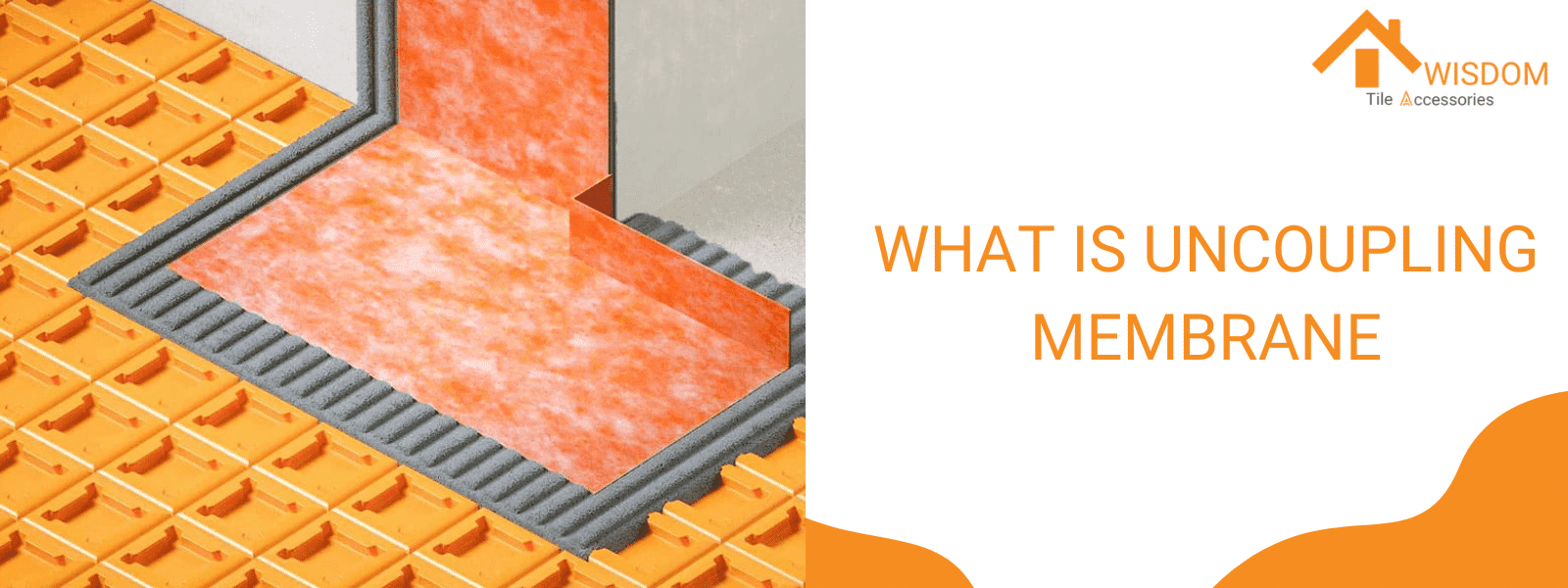

What is Uncoupling Membrane?

An uncoupling membrane serves as an underlayment designed for use beneath tile and stone installations. It functions by creating a physical barrier between the tile and the substrate, effectively allowing for independent movement of the two layers.

This separation helps to mitigate the transmission of stresses from the substrate to the tile layer. The construction of the membrane typically involves materials that are capable of accommodating these differential movements, such as a dimpled, heavy-duty plastic or a woven synthetic fabric.

>> See Our Guide: 14 Tile Underlayments You Need to Know

What Actually Does an Uncoupling Membrane Do?

Crack Prevention

Uncoupling membranes mitigate the transfer of stress between the tile layer and the substrate which can lead to tile and grout cracking. The membrane allows the tile to move independently from the substrate, addressing differential movement that could cause damage.

Waterproofing

These membranes serve as barriers that prevent moisture from reaching the substrate, thereby protecting the structure and material beneath the tile installation.

Vapor Management

The structure of uncoupling membranes provides channels that facilitate the flow of vapor away from the substrate, thereby reducing the potential for moisture accumulation that can lead to structural issues.

Load Distribution

Uncoupling membranes distribute the load from the tile surface more evenly across the substrate. They contain a grid structure that helps to spread out the forces exerted on the tile, reducing the likelihood of breakage under mechanical pressure.

Sound Reduction

Certain uncoupling membranes are designed to reduce sound transmission. These membranes typically incorporate materials that absorb or dampen sound, beneficial in environments where noise reduction is required.

Thermal Insulation

Some uncoupling membranes offer thermal insulation properties by providing a thermal break in the floor assembly. This can aid in maintaining consistent floor temperatures and improving the efficiency of heating systems, such as radiant heating.

When to Use Uncoupling Membranes?

Over Concrete Substrates

Uncoupling membranes are essential in situations involving concrete substrates under specific conditions. They are used over young or "green" concrete that has not fully cured, typically when less than 28 days old. This is because young concrete tends to shrinkage and may crack as it cures.

Besides, these membranes are beneficial for concrete slabs that are prone to movement, expansion, or contraction, which could otherwise lead to tile damage. They are also applied over concrete with surface irregularities like depressions or high moisture levels, where there is a risk of adhesion problems and subsequent tile failure.

On Wood Subfloors

In settings with wood subfloors, uncoupling membranes provide a solution where additional stiffening layers such as cement boards are not necessary. They are particularly useful over single sheet plywood subfloors that are supported by joists spaced 19.2 inches or less on center. The membrane acts to accommodate the natural movement of wood and helps to distribute the load evenly, preventing tile cracking.

On Problematic Surfaces

Uncoupling membranes are advantageous on surfaces where tile adhesion is challenged by the substrate characteristics. These include oily asphalt or extremely smooth surfaces where traditional adhesives struggle to bond effectively.

Also, these membranes are appropriate for use on substrates that are known to move or crack, providing a stable foundation for tile installation that can flex without transferring stress to the tile layer.

In Moisture-Prone Areas

For installations in areas exposed to significant moisture, such as shower floors, countertops, and below-grade or outdoor applications, uncoupling membranes offer a waterproof barrier. They prevent moisture ingress that can damage the substrate and lead to mold growth. Proper seam taping in these applications ensures a continuous moisture barrier.

For Large Format Tile Installations

Large format tiles benefit from the use of uncoupling membranes as they help to provide better support and reduce lippage between tiles. These membranes distribute the load more effectively across the tile surface, making them ideal for large tile pieces where uneven floor levels can lead to aesthetic and functional issues.

In Areas Prone to Substrate Movement or Settling

In homes with wooden subfloors or in regions with clay-rich soils, uncoupling membranes are particularly beneficial. These environments are susceptible to substrate movement or settling, conditions that can lead to tile damage if not properly managed. The membrane accommodates this movement, preventing the transfer of stresses to the tile.

5 Types of Uncoupling Membranes

Cement-Based Membranes

Cement-based uncoupling membranes consist of a blend of cement and polymers, applied as a thin layer directly onto the substrate using thin-set mortar. Once dried, these membranes create a robust surface ideal for tiling, particularly in areas subjected to heavy loads or high traffic. Their strength and durability make them suitable for commercial spaces and areas requiring a firm, stable tiling surface.

Polyethylene Membranes

Polyethylene membranes are flexible, waterproof materials typically available in rolls or sheets. These uncoupling membranes are attached to the substrate using thin-set mortar or adhesive. Known for their excellent moisture barrier properties, they are commonly used in wet areas like bathrooms and kitchens to prevent water damage and mold growth.

Sheet Membranes

Sheet membranes share many properties with polyethylene membranes, being made of similar flexible, waterproof materials. They are also applied to substrates via adhesion methods and provide reliable moisture protection, making them suitable for use in areas prone to water exposure.

Liquid Membranes

Liquid uncoupling membranes are applied as a liquid coating directly on the substrate and then allowed to dry, forming a continuous waterproof barrier. These membranes are highly flexible and can conform to various surface shapes and complexities, making them ideal for irregular or intricate tile layouts. They are particularly effective on surfaces that may require a seamless waterproof layer.

Fleece-Backed Membranes

Fleece-backed membranes combine the properties of sheet membranes with an additional layer of fleece to enhance bonding strength with the thin-set mortar. These membranes are straightforward to install and provide excellent crack isolation properties, helping to maintain the integrity of the tile surface over substrates that may experience movement or settling.

How to Install Uncoupling Membranes

1. Prepare the Substrate

Ensure that the substrate is clean, dry, and free of debris or contaminants. For wood substrates, verify that all subfloor panels are securely fastened to the framing members. Repair any cracks or imperfections in the substrate to provide a level surface for the membrane.

2. Measure and Cut the Membrane

Measure the area where the membrane will be installed. Cut the membrane to the required size using a utility knife or scissors, leaving a small gap, about 1/8 inch, between the membrane edges and any walls or other fixed structures.

3. Apply Thinset Mortar

Apply a modified thinset mortar suitable for wood substrates. Ensure that the thinset is compatible with the substrate and the uncoupling membrane.

4. Install the Membrane

Spread the thinset mortar evenly over the substrate using a notched trowel. Place the membrane onto the thinset, pressing firmly to adhere it to the substrate. Use a float or roller to remove air pockets and ensure good contact between the membrane, mortar, and substrate.

5. Seal Joints and Seams

Seal all joints and seams in installations involving sheet or fleece-backed membranes using waterproofing tape or bands to prevent moisture ingress.

6. Allow for Proper Drying

Allow the thinset mortar to dry completely after the membrane installation before proceeding to tile installation.

7. Install Tile

Begin tiling over the dried and secured membrane using appropriate tiling techniques and adhesives.

Pro Tips

- Follow manufacturer recommendations for setting materials and movement joint requirements.

- Use a compressible polyethylene gasket for perimeter movement joints to accommodate expansion and contraction.

- Align lugs or patterns correctly when using multiple sheets of membrane to ensure consistent installation.

FAQs about Uncoupling Membranes

Do I Need an Uncoupling Membrane Over Plywood?

Yes, an uncoupling membrane is recommended over plywood substrates when installing tile. While primarily used over concrete to prevent tile cracking due to substrate movement, it serves a dual function over plywood by providing a waterproof barrier. This is particularly beneficial as plywood is moisture-sensitive, and the membrane prevents water from warping or damaging the wood beneath the tile surface.

What is the Difference Between Waterproofing Membrane and Uncoupling Membrane?

Waterproofing membranes and uncoupling membranes, while both useful for tile installations, serve different primary functions. A waterproofing membrane is specifically designed to prevent water penetration and protect the substrate from moisture damage. In contrast, an uncoupling membrane primarily aims to prevent cracks in tile and grout by decoupling the tile from the substrate movements. However, many uncoupling membranes also incorporate waterproofing features, offering a combined benefit.

What Kind of Thinset for Uncoupling Membrane?

For installing tiles over an uncoupling membrane, it is generally recommended to use a non-modified thin-set mortar that meets ANSI A118.1 standards. This type of mortar ensures a strong bond without added polymers, which are necessary for installations directly onto plywood or drywall but not required when a membrane is used. It's important to follow the specific recommendations of the uncoupling membrane manufacturer to ensure compatibility and optimal performance.

Decoupling vs Uncoupling Membrane?

The terms "decoupling" and "uncoupling" are often used interchangeably in the context of tile installation membranes, but they refer to the same fundamental concept. Both decoupling and uncoupling membranes serve the primary function of separating the tile layer from the substrate, which allows for independent movement between these two layers.