https://en.wikipedia.org/wiki/CorrosionStainless steel trim plays a pivotal role in modern construction, bridging durability with refined detailing across residential and commercial projects. From protecting tile edges in a humid bathroom to reinforcing stair treads on a coastal balcony, the right grade—304, 316, or 316L—ensures your work stands the test of time. Choose poorly, and you risk rust within a year or costs that outweigh the savings. This guide compares these three grades to equip builders, architects, and property owners with the facts needed to select stainless steel trim that matches project demands. Whether it’s a budget-friendly interior or a weather-beaten exterior, the stakes are clear: grade selection drives performance.

What Is Stainless Steel Trim in Building Projects?

Role in Construction and Design

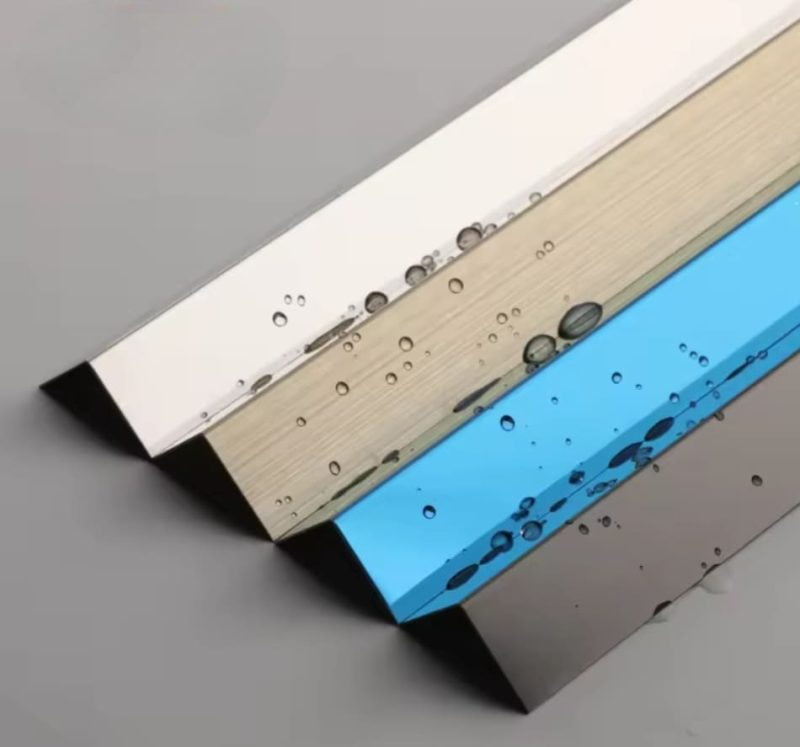

Stainless steel trim refers to corrosion-resistant metal strips engineered to shield and finish edges, corners, and transitions in construction. These components protect vulnerable surfaces—like tile perimeters or wall bases—from wear, while delivering a brushed or polished edge that elevates a space’s look. In architectural applications, their resistance to rust and ease of maintenance make them essential for high-moisture areas, such as kitchens, or high-traffic zones, like office lobbies. Contractors value them for combining structural support with a streamlined appearance that lasts decades.

Key Applications in Architecture

Stainless steel trim serves diverse roles in construction, enhancing both durability and design:

- Stainless steel tile trim: Secures ceramic or porcelain edges, preventing cracks in wet areas like showers or poolside floors.

- Stainless steel skirting trim: Shields wall bases from scuffs, adding a sharp metallic border to upscale homes or offices.

- Stainless steel stair nosing: Reinforces step edges, cutting slip risks on busy staircases in schools or hotels.

- Stainless steel transition strips: Smooths shifts from carpet to tile, keeping floors level in open-plan layouts.

- Stainless steel movement joints: Flexes with large tiled surfaces, preventing cracks in retail or commercial spaces.

- Stainless steel wall protectors: Guards corridors from impacts, ideal for hospitals or warehouses.

These applications highlight why stainless steel trim remains a trusted choice for long-lasting building projects.

Why Stainless Steel Grades Impact Construction?

Alloy Composition Basics

A stainless steel trim’s performance in construction rests on its alloy blend. Chromium, at 18% in 304 and 316, forms an oxide shield against rust. Nickel, ranging from 8% in 304 to 10-14% in 316, adds strength and a glossy finish. Molybdenum, exclusive to 316 and 316L at 2-3%, resists corrosion from salts—crucial for oceanfront builds. These alloys govern whether a trim survives a humid warehouse or pits on a coastal terrace.

Risks of Choosing the Wrong Grade

Grade errors can cost builders dearly in repairs and reputation:

- Rust in humid climates: 304 trim on a tropical porch pits in 18 months; 316 holds firm for five years.

- Higher replacement costs: A corroded stainless steel stair nosing in a damp lobby adds 30% to upkeep over a decade. Rust doesn’t just mar aesthetics—it forces early fixes, proving grade choice is a bottom-line issue.

304 Stainless Steel Trim: The Cost-Effective Choice

Core Properties

304 stainless steel trim blends economy with utility for indoor projects. Its 18% chromium and 8% nickel mix offers moderate corrosion resistance, perfect for dry climates. High strength lets it withstand shaping, while its flexibility suits fast installs—contractors swear by its ease on tight schedules.

Best Scenarios for 304 Trim

For jobs where moisture stays low, 304 trim excels:

- Stainless steel tile trim in kitchens: Guards edges near counters with a blemish-free finish for years.

- Stainless steel skirting boards in offices: Deflects light scuffs, ideal for budgets under $500. It’s the practical pick when cost outweighs corrosion concerns.

316 Stainless Steel Trim: Built for Tough Conditions

Core Properties

316 stainless steel trim excels in harsh climates thanks to its alloy mix. With 18% chromium and 10-14% nickel, it resists basic corrosion, but the 2-3% molybdenum addition counters salt and acid damage. This grade prevents pitting in chloride-heavy areas—like poolside decks—where lesser trims fail fast. Designers turn to it for projects needing corrosion resistance that lasts 15 years over 304’s five.

Best Scenarios for 316 Trim

316’s alloy shines in these rugged applications:

- Stainless steel stair nosing on coastal properties: Defies salt spray, securing steps for over a decade.

- Stainless steel wall protectors in high-humidity spas: Resists steam corrosion, keeping walls pristine. Its strength in wet, salty conditions pays off in durability for exposed structures.

316L Stainless Steel Trim: The Welder’s Favorite

Core Properties

316L stainless steel trim tweaks 316’s recipe for fabrication ease. Its carbon drops to 0.03%, stopping weld decay—rust at joints that plagues higher-carbon grades. Matching 316’s 2-3% molybdenum, 18% chromium, and 10-14% nickel, it fights corrosion while bending and welding smoothly. Welders value its precision for flawless joins under heavy use.

Best Scenarios for 316L Trim

316L fits these precision-driven builds:

- Stainless steel transition strips in luxury interiors: Welds seamlessly for smooth carpet-to-tile lines.

- Stainless steel movement joints in industrial floors: Holds up vast tiled spans in factories, crack-free. It blends toughness with flexibility, ideal for intricate, long-lasting designs.

Comparing 304, 316, and 316L Trim Head-to-Head

This section tests 304, 316, and 316L stainless steel trim to their limits, laying out their strengths in construction. From rust resistance to install ease, these grades face off with lab data, field cases, and a table to clarify which excels where.

Corrosion Resistance in Construction

Corrosion resistance dictates trim lifespan across climates:

- 304 vs. 316/316L: 304 fits dry offices but corrodes in salty air—pitting at 500 hours in ASTM B117 salt-fog tests. 316 and 316L, with molybdenum, hit 2,000 hours, thriving in 80% humidity zones like coastal roofs.

- Field evidence: A 2022 Florida condo refit saw 304 stainless steel stair nosing rust in 18 months under salt spray; 316 lasted eight years. Indoors, a Midwest mall’s 304 tile trim stayed pristine for 10 years. ASTM data shows 316/316L outlasts 304 by 50% in corrosive settings—a must for wet builds.

Cost vs. Value Breakdown

Costs vary by lifespan; see the details:

- 304’s savings: Stainless steel tile trim in 304 costs $1.50-$2 per foot, undercutting 316/316L’s $2-$3 by 30%. A 10-foot stainless steel skirting trim saves $5-$10.

- 316/316L’s endurance: In damp air, a 304 stainless steel flat strip lasts five years; 316 reaches 15, halving replacements. For a 20-year school hall, 316 saves $50 per 100 feet. Contractors see it clear: 304 rules five-year flips, while 316/316L anchors lasting commercial jobs.

Fabrication and Installation Factors

Install traits guide grade picks in the field:

- 316L’s weld advantage: Its 0.03% carbon stops weld rust, ideal for custom stainless steel wall trim in curved layouts.

- Cutting ease: 304 and 316 stainless steel transition trim shape in 10 minutes per 10 feet with carbide saws; 316L flexes for tight bends in stair nosing. Per 2023 logs, 316L speeds welding 25% on intricate setups, while 304 suits quick office installs.

Comparison Table

Feature | 304 Trim | 316 Trim | 316L Trim |

|---|---|---|---|

Corrosion Resistance | Moderate (dry zones) | High (80% humidity) | High (80% humidity) |

Salt-Fog Test (Hours) | 500 | 2,000 | 2,000 |

Cost per Foot | $1.50-$2 | $2-$3 | $2-$3 |

Lifespan in Damp Air | 5 years | 15 years | 15 years |

Welding Suitability | Standard | Standard | Top (no weld rust) |

Best Use | Indoor trim, skirting | Coastal nosing, walls | Welded joints, transitions |

Verdict: 304 fits dry, tight budgets; 316 rules wet durability; 316L tops welded precision—match your build to the winner.

How to Pick the Perfect Stainless Steel Trim?

Matching Grade to Environment

Site conditions guide your choice:

- Dry interiors: 304 stainless steel trim guards kitchens or lobbies, rust-free in low humidity.

- Wet or coastal: 316/316L stainless steel trim thrives in oceanside homes or pool halls, resisting salt damage. Grade fit ensures a decade of use in the right climate.

Balancing Budget and Performance

Job scope sways the decision:

- Short-term builds: 304’s $10 savings on a 10-foot stainless steel transition strip suits rentals or flips.

- Long-term assets: 316/316L’s $5-$10 extra per stainless steel wall trim lasts 20 years in public spaces. Cost aligns with lifespan goals for max return.

Maintenance Needs Over Time

Upkeep hinges on grade and wear:

- Wall protectors: 304 needs a wipe every six months in dry corridors; 316 cuts to yearly in humid clinics.

- Transition strips in traffic zones: 304 lasts five years in stores; 316/316L hits 12 with a yearly buff. 316/316L’s low care saves time in busy builds.

Conclusion

After testing 304, 316, and 316L stainless steel trim across corrosion, cost, and fabrication, the choice boils down to your build’s needs. 304 delivers affordability—perfect for dry, budget-driven interiors like office skirting or kitchen tile trim, where $1.50 per foot keeps costs low. 316 offers resilience—its molybdenum edge shines in wet, salty zones, securing coastal stair nosing or spa wall trim for 15 years. 316L brings precision—its weld-friendly design suits custom movement joints or luxury transition strips, blending durability with flawless joins. Contractors know no single grade tops all; it’s about fit. Pick 304 for tight wallets in mild climates, 316 for tough weather, or 316L for intricate installs. Align your trim grade to your project’s location and demands—coastal humidity calls for 316, while a quick indoor flip leans on 304—and you’ll nail the best pick every time.

FAQ: Stainless Steel Trim Questions Answered

How Can You Cut Stainless Steel Trim Without Damaging It?

Use a carbide-tipped saw at 1,500 RPM to prevent heat burns on stainless steel tile trim. For thin pieces, a metal shear cuts clean in seconds. Thicker stair nosing needs coolant spray—contractors report zero warping with this trick.

How Do You Calculate the Weight of Stainless Steel Trim for a Project?

Multiply length (m), width (m), and thickness (mm) by density: 7.93 g/cm³ for 304, 8.0 g/cm³ for 316/316L. A 2m x 0.05m x 1mm 304 stainless steel flat strip weighs 0.79 kg—key for shipping or cost bids.

How Does Stainless Steel Trim Price Affect Project Costs?

Nickel and molybdenum hikes—up 20% in 2022-2023 per LME—push 316/316L stainless steel wall trim to $3 per foot. For a 100-foot coastal job, that’s $150 more than 304’s $150, but 316’s 15-year life cuts redo costs by 40%.

Which Stainless Steel Trim Grade Needs the Least Maintenance in High-Traffic Areas?

316L needs the least—yearly wipes in humid clinics vs. 304’s six-month scrubs in dry stores. ASTM cleaning tests show 316L on stainless steel transition strips saves 50% upkeep time in busy malls over 10 years.

How Long Does Stainless Steel Trim Last in Harsh Weather?

In storms or salt air, 316/316L stainless steel stair nosing lasts 15-20 years—304 fades in 1-2. A 2021 Texas pier refit logged 316 at 90% intact after five hurricane seasons, per coastal engineer notes.