Why are more and more modern buildings choosing to use transition strips? Welcome to read this ultimate guide on transition strips, where you will gain a comprehensive understanding of the different types of transition strips and their application scenarios. Let's explore the presence of transition strips in modern architecture from a professional perspective.

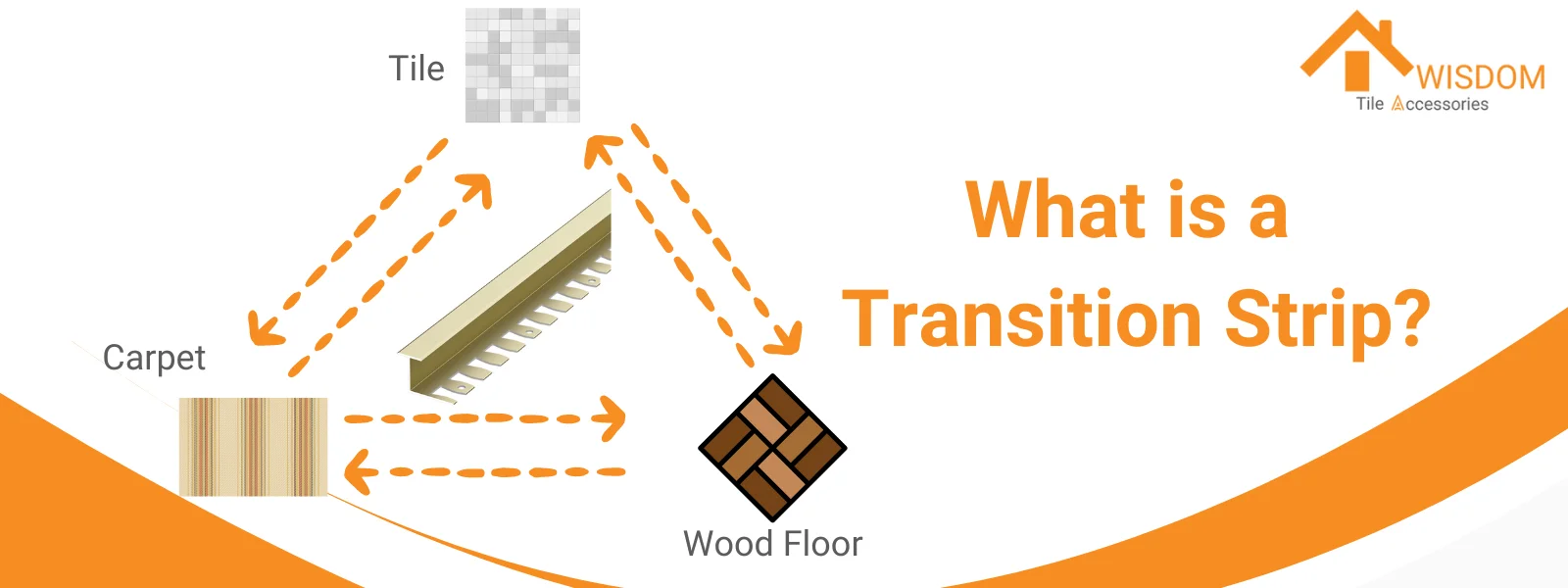

What is a Transition Strip?

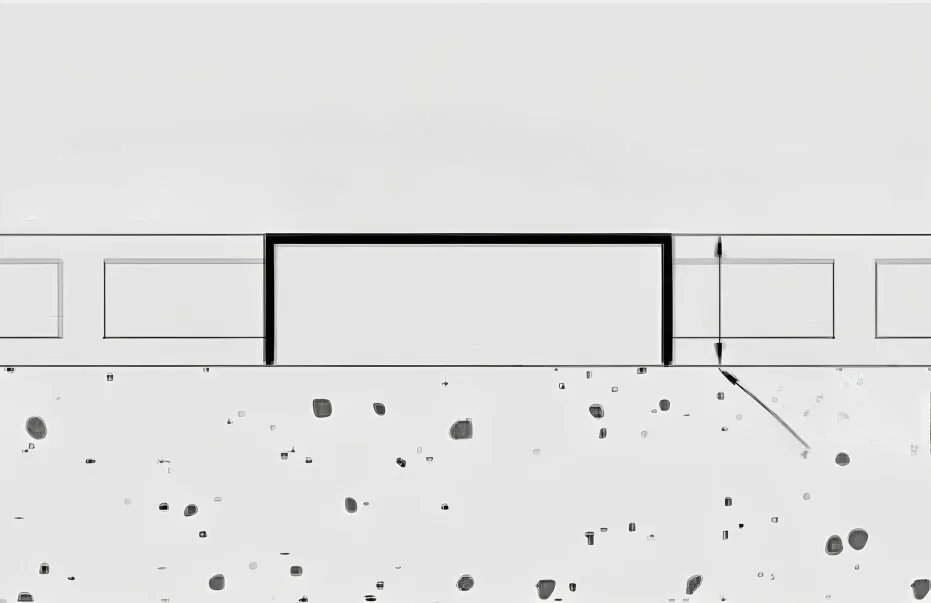

Transition strips, also known as seam binders or threshold ramps, are narrow strips of material that bridge the gap between two different flooring types. They come in a variety of shapes, sizes and materials, allowing for seamless transitions between floors of different heights.

Generally speaking, transition strips are primarily used between tiles, wooden floors, and carpets to bridge the gap between them.

Why do you need a transition strip?

The benefits of transition strips become particularly evident when there is a significant height difference, such as transitioning from a thicker to a thinner floor or from a bathroom door to a hallway laminate floor.

Because they can effectively prevent tripping by reducing the height disparity between different types of flooring or floor coverings, minimizing the likelihood of stumbling.

Additionally, transition strips visually differentiate from the surrounding flooring, serving as a visual cue to reduce tripping hazards.

Even when the floors are level, there are numerous advantages to using transition strips:

- Aesthetically, they can conceal gaps between different types of flooring, creating a consistent visual atmosphere throughout the space.

- Functionally, transition strips can mitigate the expansion and contraction of wood floors due to temperature and humidity changes. Moreover, the transition strips installed at doorways can also partially dampen the noise generated when opening and closing doors.

Tips: While the use of transition strips is not necessary in modern building codes, they have become a popular choice in current trends and among industry professionals. This is because they not only improves the aesthetics of the interior, but also the safety.

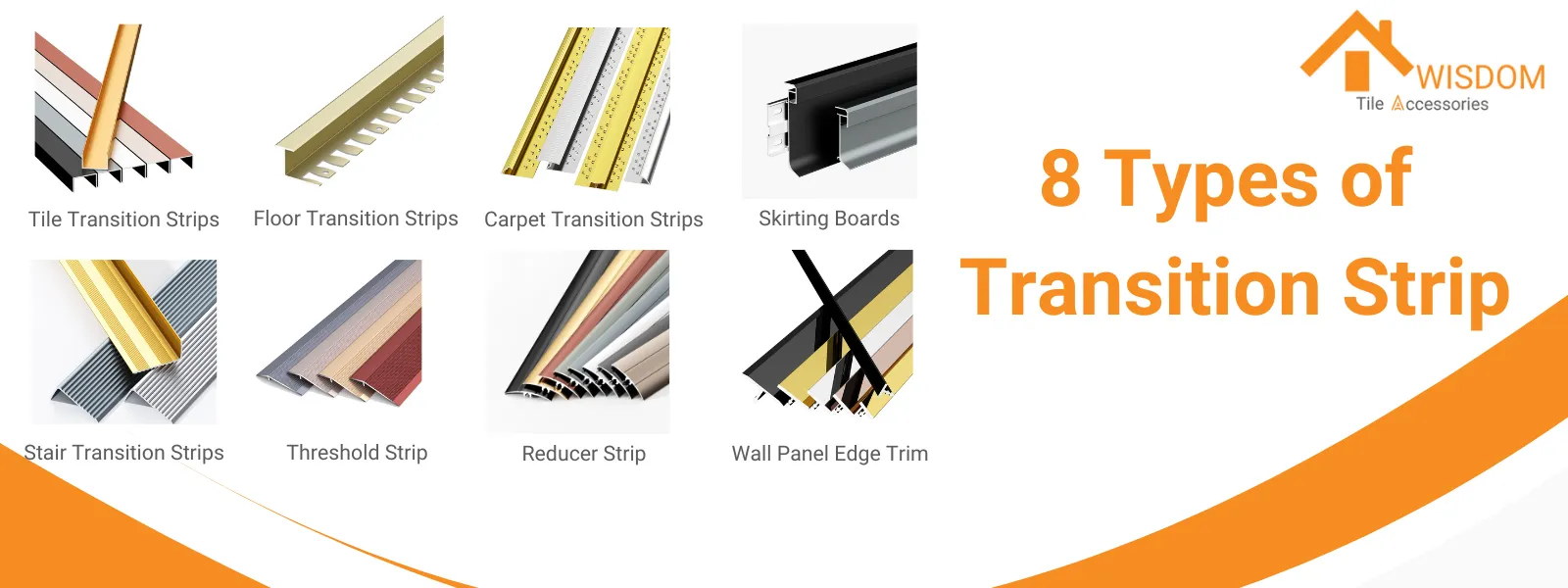

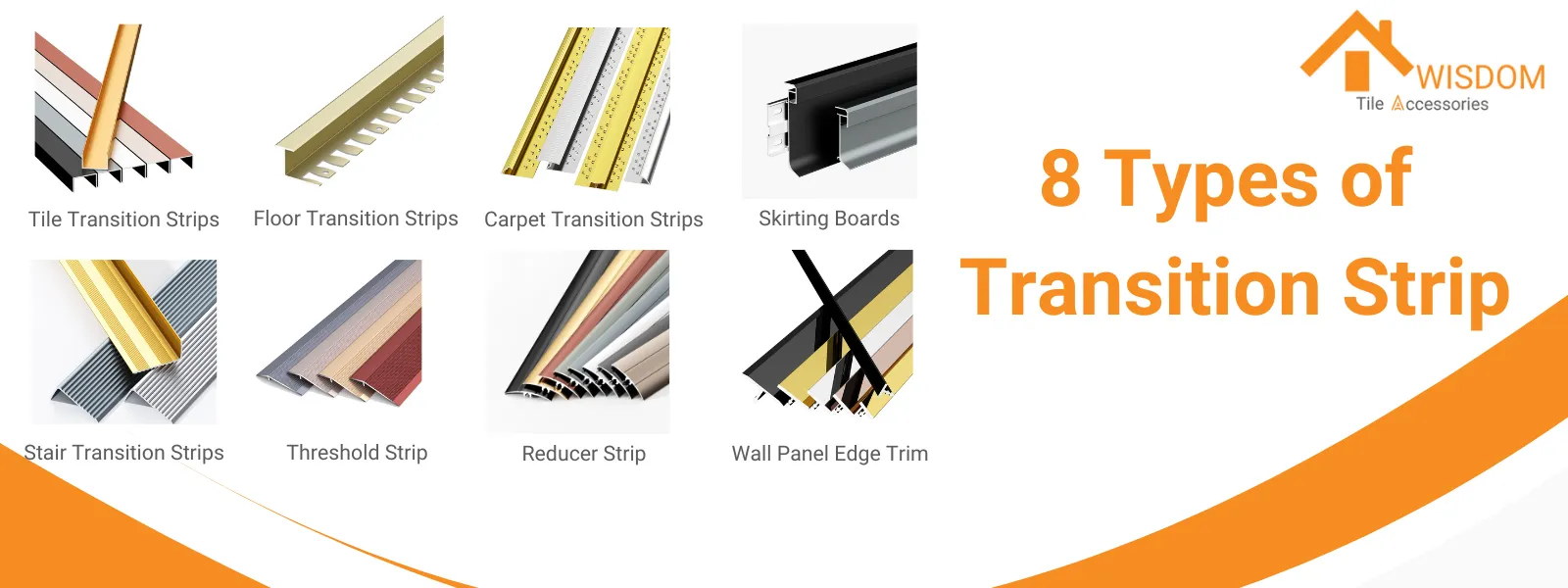

The Main 8 Types of Transition Strip

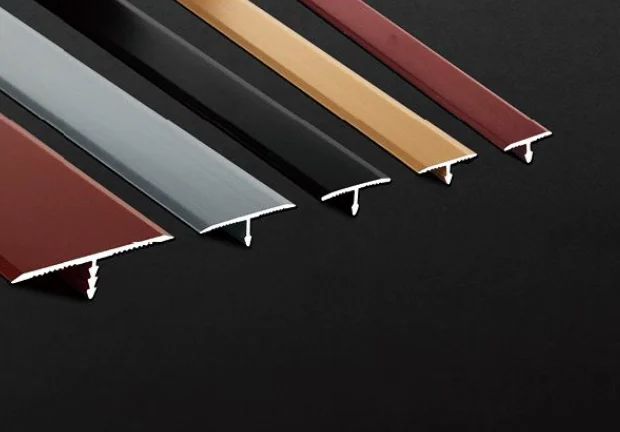

Transition strips are primarily made from aluminum alloy, stainless steel, brass, and PVC, and come in various shapes such as T-shaped, U-shaped, etc.

In the construction industry, these strips are generally categorized based on their application scenarios, highlighting the diverse purposes of different types of transition strips.

Here is a detailed introduction to 8 types of transition strips.

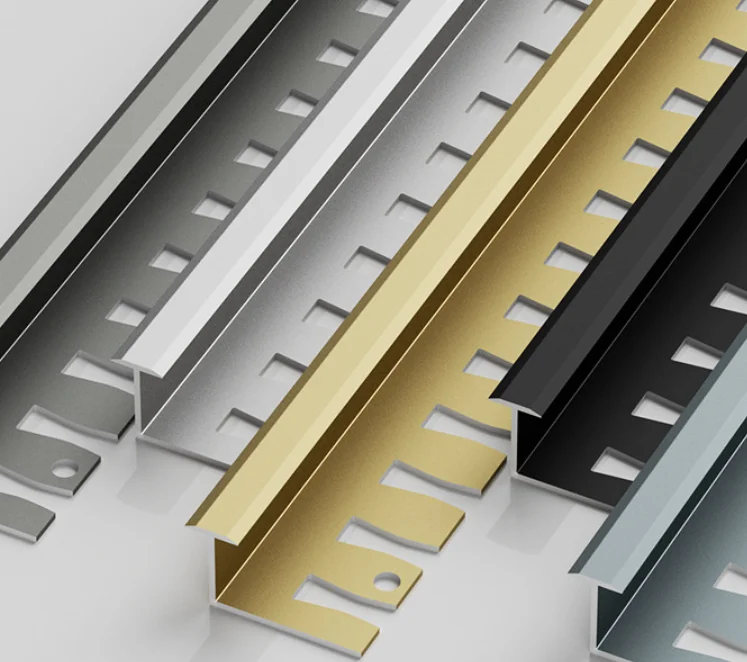

1. Tile Transition Strips

Tile transition strip, a narrow strip specifically designed for transitioning between tiles, primarily protects the edges of the tiles to prevent damage. Besides, it offers a seamless transition from tiles to other floor coverings, which enhances the aesthetic and safety of tile flooring.

Here are 3 common applications of tile transition strips:

- Tile to Tile Transition Strip

- Tile to Wood Floor Transition Strip

- Tile to Carpet Transition Strip

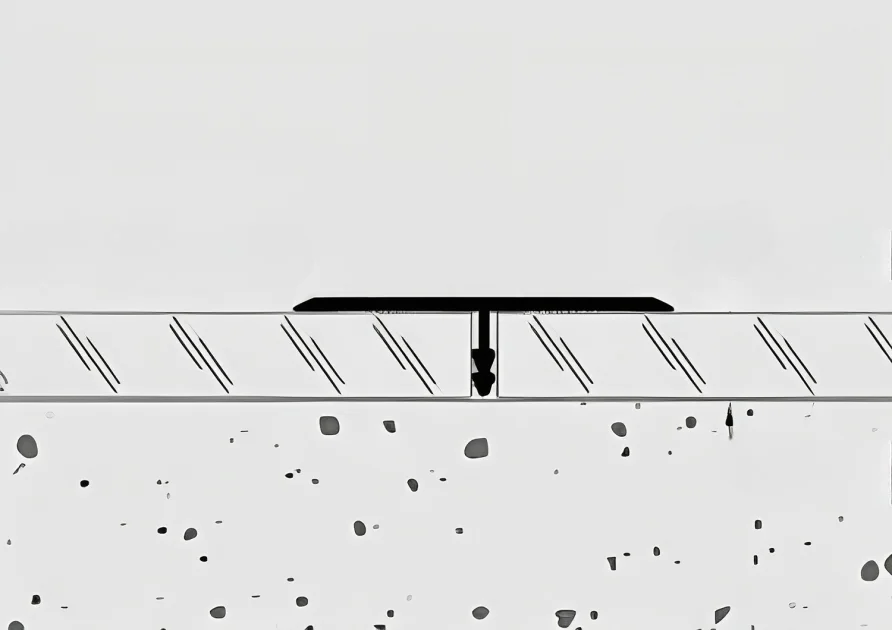

In addition, tile transition strips come in T-shaped and U-shaped varieties. T-shaped ones are suitable for smaller tile gaps and can connect hard surface floors of the same height.

Due to the slight elevation of the T-shaped top above the tile surface, it also serves as a shock absorber when used on tile floors.

U-shaped tile transition strips have a more elegant and concise appearance, and they are suitable for larger tile gaps. Thanks to their flat top design, U-shaped transition strips achieve a seamless transition between tiles.

In high-traffic areas like hotel lobbies, U-shaped tile transition strips are commonly used. Because they can reduce the risk of tripping and providing a sophisticated aesthetic.

>> See U-Shape Tile Transition Strip

2. Floor Transition Strips

Floor transition strips are used to transition from one type of floor to another or other floor coverings. Compared to tile transition strips, they are more widely used and applicable in various settings, especially on wooden floors.

As one type of transition strip, floor transition strips not only provide basic aesthetics and safety but also effectively protect floors from damage and cracking.

>> See Latest Aluminum Floor Transition Strip

This is because wooden floors absorb moisture in high humidity, causing expansion. And release moisture in low humidity, causing contraction.

Due to the flexibility of floor transition strips, they can counteract the stress generated by the expansion of wooden floors, thereby providing protection. Additionally, they can prevent the wooden floor from deviating from its position.

>> See Flexible Floor Transition Strip

>> See How to Install Flexible Transition Strip

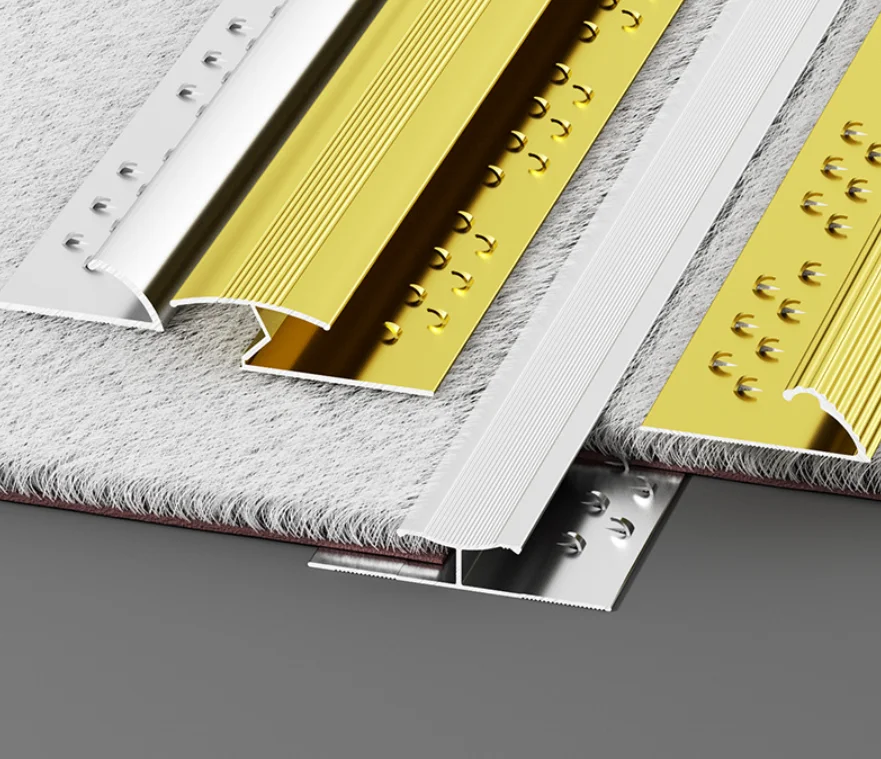

3. Carpet Transition Strips

Carpet transition strips are used to bridge the gap between carpet and other types of flooring materials.

For Example:

Carpet to Carpet transition

……

Additionally, carpet strips can secure the carpets to the floor, preventing them from sliding or coming loose. This is due to their unique hook design, which effectively grips the carpet.

Moreover, these carpet strips provide a noticeable end for the carpet edge, enhancing overall appearance and durability.

>> See Aluminum Carpet Transition Strip

Tips:

According to ICC A117.1 Chapter 3, “Where edge trim is used in making the transition from a carpeted surface to some other flooring material, it must comply with the limitations for vertical changes in level. If vertical, a maximum 1/4 -inch elevation change is permitted. If the change is more than 1/4 inch but does not exceed 1/2 inch, a bevel is required with a maximum slope of 1:2.”

Therefore, when selecting carpet transition strips, please adhere to standard specifications. If you have any requirements, feel free to contact us. Awisdom will provide carpet strips that comply with standard sizes and professional guidance.

4. Skirting Boards (Floor to Wall Transition)

Skirting boards, also known as baseboards, are used to achieve a transition from the floor to the wall. This particular type of transition strip can cover gaps between the floor and the bottom of the wall, which provides a stylish appearance while preventing dust and dirt accumulation in corners.

By the way, skirting boards are primarily made of stainless steel and are commonly used with various accessories such as inside corners, outside corners, joint clips, and end caps.

Additionally, skirting boards can be directly installed on wooden floors without a subfloor, as long as the purchased product is designed accordingly.

>> See Subfloor-Free Stainless Steel Skirting Boards

>> See How to Install Your Skirting Boards

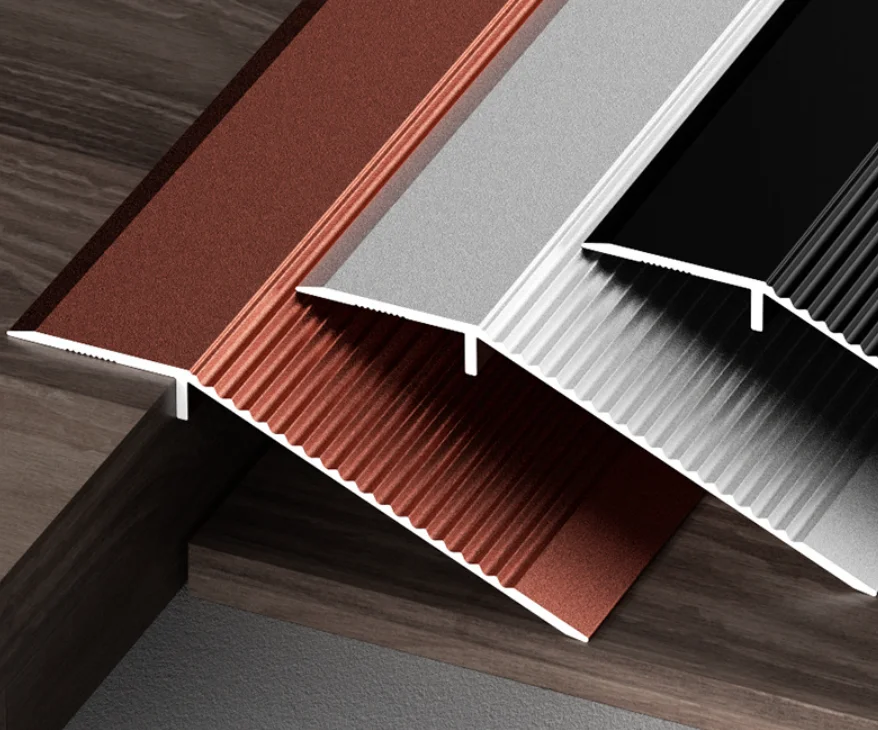

5. Stair Nosing (Stair transition strips)

Stair nosings, also known as stair transition strips. They are installed on the edges of stairs. They can facilitate the transition from the floor to the stairs and the transition between the stair tread and riser.

Generally, they are attached directly to the stairs using adhesive or can be selected as self-adhesive stair nosings.

There are five main types of stair nosings. They are both designed to enhance stair safety, preventing tripping while also serving a decorative purpose to add unique style to stairs.

For more information on stair nosing selection tips and types, please refer to our stair nosing guide.

>> See 5 Types of Nosing to Upgrade Your Stairs in 2023

>> See Stair Transition Strips Category

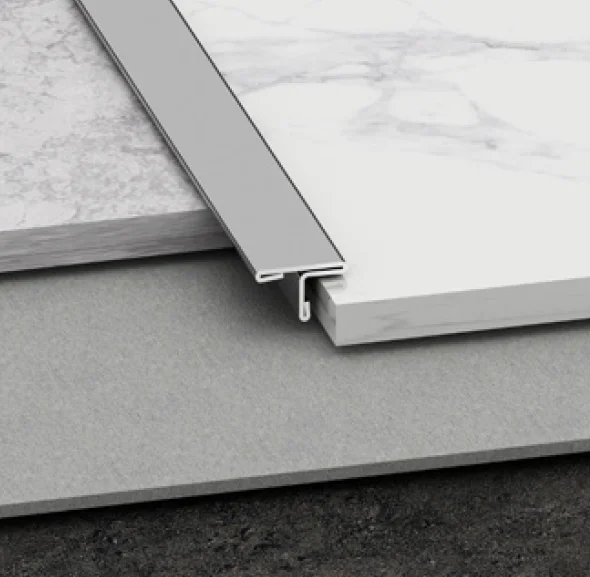

6. Threshold Strip

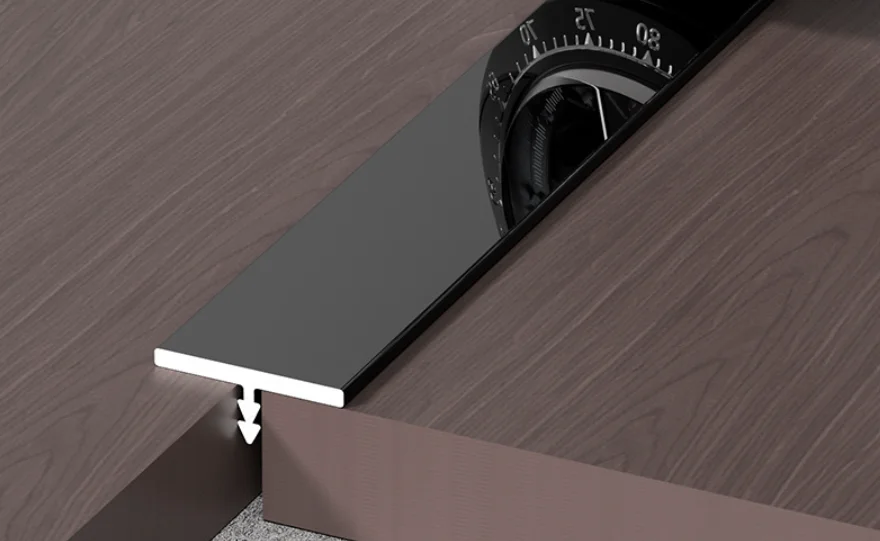

Threshold, known as metal threshold strips, it's usually used to transition from a hardwood floor to a lower profile floor, carpet or tile with a thickness that is less than that of the wood. You can also use this to cover expansion gaps where you can't use a quarter round like around the fireplace or sliding glass doors devolving.

>> See Flooring Threshold Strip

7. Reducer Strip

Reducer, is also called a floor reducer transition strip. And it's used to transition from a high floor down to a low floor like concrete vinyl or thin carpeting. The height of the molding on one side is equal to the thickness of your floor and it tapers down over roughly two inches to make a smooth transition.

8. Wall Panel Edge Trim

Wall panel edge trim is used to connect two panels on a wall, achieving a seamless transition between walls or between walls and ceilings. It comes in types such as internal corners, external corners, end caps, and H-shaped connecting decorations.

The wall panel trim can enhance the stability between two panels, concealing unsightly gaps on the wall and presenting a fashionable transition. Additionally, it can also serve to protect the edge of the wall panels from damage caused by collisions.

How to Choose Right Materials of Transition Strip

The previous section introduced 8 types of transition strips based on application scenarios. In fact, common materials for these strips include metal, hardwood, laminate, rubber, and PVC. Each material offers its own advantages when handling various floor transitions. Let's now explore transition strips from the perspective of materials and compare their pros and cons.

Metal Transition Strip

A metal transition strip is a material, typically made of aluminum, stainless steel, or brass, used to seamlessly join different flooring types in a building, providing a clean and professional look.

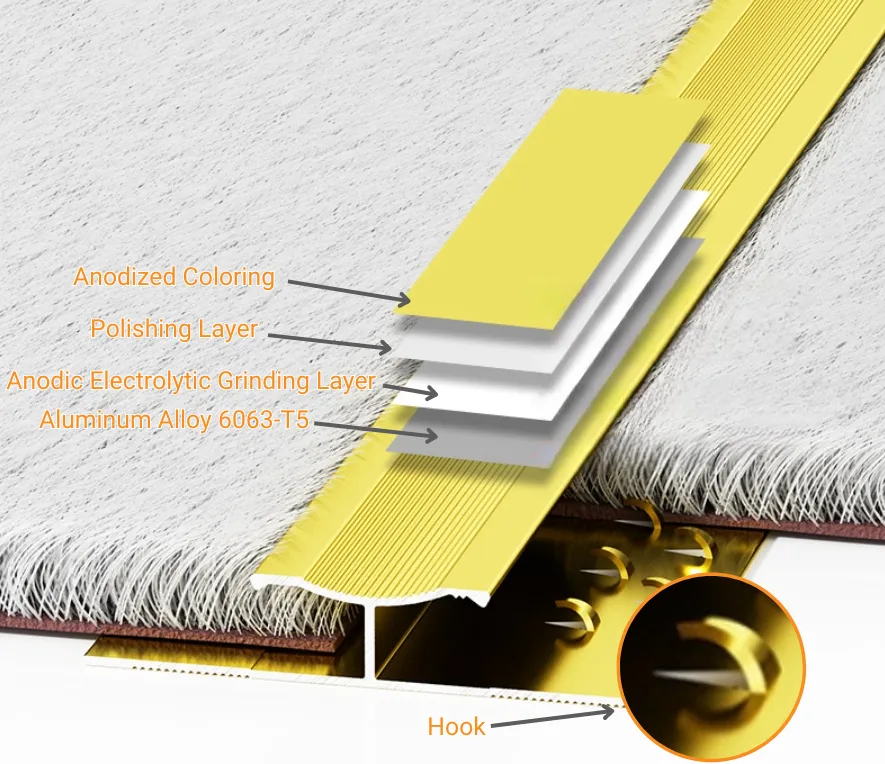

Aluminum Transition Strips: Due to their cost-effectiveness, strength, and durability, aluminum transition strips are widely popular in commercial and engineering environments. They have a broad range of applications and can be customized to mimic the appearance of high-end finishes like brass, steel, or chrome, while maintaining the strength and low cost of aluminum.

Aluminum is known for its high strength, flexibility, and corrosion resistance, making it an ideal material for floor transitions.

Therefore, aluminum transition strips are suitable for customers with design requirements for shape, size, and color.

Brass Transition Strip: They are commonly used in high-end projects such as luxury hotels, office buildings, and theaters. Brass transition strips also have a sophisticated appearance and are relatively sturdy.

Another reason for choosing brass transition strips is their long lifespan, high compressive strength, and recyclability. Additionally, brass is highly malleable and can be shaped into various forms like T-shaped, U-shaped, square, etc.

Individuals with customization requirements may consider using brass transition strips. However, brass is less durable than aluminum and is not suitable for industrial environments.

Stainless Steel Transition Strip: Made from 304 or 316 stainless steel, the stainless steel transition strips are known for their exceptional durability in high-traffic areas. They are easy to clean and maintain, making them advantageous in environments with high hygiene requirements, such as healthcare facilities or restaurants.

In terms of appearance, stainless steel transition strips come in various heights, surface treatments, and colors, including silver, champagne, rose gold, black, and titanium gold. This diversity provides extensive choices for design and is favored by architects and designers.

Hard Wood Transition Strip

Hardwood transition strips are often used when connecting two different types of flooring, such as tile and laminate. They are typically about 2 inches wide and can be stained to match the color of the adjacent flooring. This type of transition strip is particularly useful when there is a height difference between the two types of flooring, as it can create a smoother transition and help avoid tripping hazards.

Moreover, hardwood transition strips are aesthetically pleasing, especially when matched with a similar type of wood flooring. However, hardwood is always a fragile material and can easily become scuffed or scratched.

Laminate Transition Strip

Laminate transition strips are used where laminate flooring meets a door, step, or another type of flooring. They are notched on one side to cover the edge of the flooring, and the other side typically has a bullnose shape.

These laminate strips are made to match the flooring, providing a seamless transition between different types of flooring. They are relatively easy to install and are cost-effective, with prices ranging from $15 to $60 based on the length and material.

Vinyl and Plastic Transition Strip

They can provide a smooth transition without an abrupt change in height or texture. These transition strips are easy to install and help protect the edges of the flooring from damage caused by expansion and contraction due to temperature changes. And they also reduce noise from foot traffic and furniture movement.

Rubber Transition Strip

Rubber transition strips are easy to install, clean, and maintain. They are particularly useful in high-traffic areas, as they are slip-resistant and easier on the joints, making them a safer option.

Finish Your Floors With Trim and Accessories

Don't let your beautiful floors end abruptly! Awisdom's trim and accessories collection provides the perfect finishing touch, ensuring a seamless transition between materials.

Our durable and stylish solutions cater to any commercial flooring project, be it bustling retail spaces, elegant lobbies, or high-traffic corridors. Let our trim and accessories be the final flourish that ties your project together. Contact us today and discover how Awisdom can elevate your floors from functional to flawless.

>> See Building Material Accessories

FAQ about Transition Strip

What is a carpet reducer?

A carpet reducer is a transition strip designed for a smooth shift from hardwood to delicate flooring like carpet. It not only enhances aesthetics but also compensates for height differences between floors, ensuring a safe and seamless connection.

What is the difference between transition strip and reducer?

A reducer is a specific type of transition strip used to connect two floors of different heights seamlessly. However, transition strips, in a broader context, include various profiles serving different purposes in flooring installations.

What is t molding?

T-Molding is a decorative molding used to transition between two surfaces of equal height, commonly seen in thresholds connecting rooms with the same flooring. Its practical function goes beyond aesthetics, helping accommodate the natural movement of engineered hardwood floors and providing protection against damage.

What is end cap molding used for?

End cap molding, also known as square nose, is versatile in transitioning laminate to carpet, masonry, sliding doors, and exterior door jambs. Beyond minimizing height differences, it adds aesthetic value by creating a polished look that complements flooring styles.

What glue to use for transition strips?

For secure attachment of transition strips, please use construction adhesive. Apply a steady bead to both the strip and the floor. This adhesive is versatile, suitable for materials like wood, laminate, concrete, metal, and more. Follow manufacturer instructions for optimal results, and consider water-resistant options for areas prone to moisture.

Does LVP need transition strips?

Yes, transition strips are essential for vinyl plank flooring. They provide a seamless transition between different flooring types or rooms with varying heights, enhancing both safety and aesthetics.

How to install transition strip

- Prepare Subfloor: Ensure a clean and level subfloor.

- Measure Doorway: Accurately measure the doorway for the strip.

- Cut Strip: Cut the transition strip to fit.

- Cut Metal Rail: If applicable, cut the metal rail to match.

- Secure Rail: Screw or glue the metal rail to the subfloor.

- Place Strip: Lay the cut strip in the doorway, ensuring a snug fit. Press down for a secure and level installation.

>> See Our Beginner Guide About Installing Transition Strip

How to cut transition strips?

- Measure the size of the doorway or area where the transition strip will be located with a tape measure. Record the measurement.

- Measure that same distance on the transition strip and mark the cut location with a black marker. Draw a straight line across the strip with the marker.

- Set the transition strip on a flat surface and use the appropriate cutting tool for the material. For metal transition strips, use a hacksaw. For laminate or vinyl transition strips, a miter saw or handsaw can be used.

- Hold one end of the transition strip with your non-dominant hand and press down firmly on the cutting tool with your dominant hand. Move the cutting tool back and forth over the transition strip until it is cut into two pieces.

- Wipe off the edges with a clean rag and remove any small shreds of material left over from the cut.

- Set the transition strip in the desired location and verify that it fits in the opening properly.

How to combine tile and wood flooring?

To combine tile and wood flooring seamlessly, use a threshold and transition to create a clear division between the two. Choose a material like metal, hardwood, or natural stone that complements both floors. Ensure accurate measurements for a snug fit, explore different transition styles, and consider professional installation for intricate designs.

How to transition tile to carpet?

- Select a Suitable Transition Strip: Choose a transition strip that complements both tile and carpet.

- Measure and Place: Position the strip about a quarter inch from the tile edge, allowing for movement.

- Prepare Tile Edge: Ensure the tile edge is clean before attaching the strip.

- Cut and Fit Carpet: Trim the carpet to align perfectly with the tile edge.

- Use a Knee Kicker: Employ a knee kicker to pull the carpet over the tile for a tight fit.

- Tuck and Secure: Tuck the carpet under the strip and use hooks or adhesive for secure placement.

- Final Touches: Inspect and trim excess carpet for a polished appearance.

How to transition carpet to vinyl?

- Measure the area where the transition will be located.

- Choose a suitable transition strip based on the height difference between the carpet and vinyl. T-moulding or reducing moulding can be used if the surfaces are close to level, while a carpet reducer or a U-shaped might be needed for a significant height difference.

- Cut the transition strip to the measured length.

- Install the transition strip. For a Z-bar, fold the carpet back, cut the tack strip to the needed length, and attach the U-shaped to the vinyl plank. For a carpet reducer or T-moulding, tuck the carpet over a tack strip, cut it off, then nail down the moulding over the carpet edge that also covers the edge of the vinyl.

- Verify that the transition strip fits properly in the opening.