Imagine a wall that appears to float just above the floor, or a ceiling that hovers independently of the walls that support it. This is not an illusion or a construction error. It is the result of a shadow gap, a deliberate and precise architectural detail that transforms simple junctions into statements of minimalist design. This recess is more than a space; it is a declaration of precision, turning what was once concealed into a celebrated feature.

What Is a Shadow Gap?

A shadow gap is a deliberate, engineered recess created where two surfaces meet. Its function is to produce a crisp, continuous line of shadow that visually separates architectural elements. This technique stands in direct opposition to traditional trims, such as skirting boards or cornices, which are applied over a joint to conceal gaps, imperfections, and the transition between materials.

By creating this negative space, the shadow gap gives walls, ceilings, and other features a distinct "floating" appearance. The wall does not terminate abruptly at the floor; it recedes, creating an illusion of depth and lightness. This detail strips away visual clutter, allowing the purity of the architectural planes to define the space.

Why Choose a Shadow Gap Detail?

The adoption of the shadow gap reflects a fundamental shift in design philosophy, moving away from concealing junctions to celebrating the precision of their construction. It is a defining characteristic of modernism and minimalism, which reject ornamentation that serves no structural or spatial purpose. A flawlessly executed shadow gap is an honest display of high-quality construction. It signals that the underlying structure is perfectly straight and true, as there is no trim to hide misalignments.

Beyond its statement of craftsmanship, the clean line of a shadow gap can alter the perception of a room. The uninterrupted vertical plane of a wall can make a space feel more expansive and open. By detaching elements from one another, the detail introduces a sense of airiness and sophistication.

Where Are Shadow Gaps Used in Buildings?

This architectural detail is versatile and can be applied to various junctions within a building to achieve a clean, contemporary finish.

At the floor instead of skirting boards

The most common application is at the base of a wall, where it replaces the traditional skirting board. This creates a recessed channel that makes the entire wall plane appear to hover above the finished floor. The detail is particularly effective with hard flooring surfaces like wood, tile, or polished concrete. For those who still desire the protective qualities of a baseboard, a hybrid solution exists: a flush-mounted skirting board with an integrated groove at its top edge, creating a shadow line while sitting level with the plaster.

At the ceiling instead of cornices

Used at the junction of a wall and ceiling, a shadow gap visually disconnects the two planes. This can make a ceiling seem higher and the room feel more spacious. The detail provides a sharp, clean perimeter that is a modern alternative to decorative cornices or crown moldings.

Shadowline vs. Square Set Ceilings

It is important to distinguish a shadowline ceiling from a square set ceiling. A shadowline detail is defined by its intentional recess, typically 10mm wide, which is specifically designed to create a shadow. In contrast, a square set ceiling is a perfectly flush 90-degree corner where the wall and ceiling meet with no gap or molding. A square set finish requires an extremely high level of plastering skill to achieve a perfect, crack-free corner.

Around doors to create a trimless look

A shadow gap can be used to frame a door, eliminating the need for traditional architraves. This creates a "trimless" or "frameless" opening where the wall plaster runs directly to a recessed edge around the door jamb. This application is notoriously difficult to execute perfectly. Architraves were invented to conceal the inevitable crack that forms as a building settles and materials move. A trimless detail exposes this joint, meaning the building's frame must be exceptionally stable and the installation flawless to prevent cracking over time.

To define wall panels and features

Beyond simple junctions, shadow gaps are an effective tool for articulating large surfaces. They can be used to separate panels of different materials, such as wood, tile, stone, or fabric. This adds a sense of rhythm, texture, and a high-end finish to feature walls, breaking up what might otherwise be a monotonous surface and highlighting the qualities of each material.

How Is a Shadow Gap Constructed?

The technical execution of a shadow gap is a process that demands precision and the correct materials. It is not an empty space left between two components.

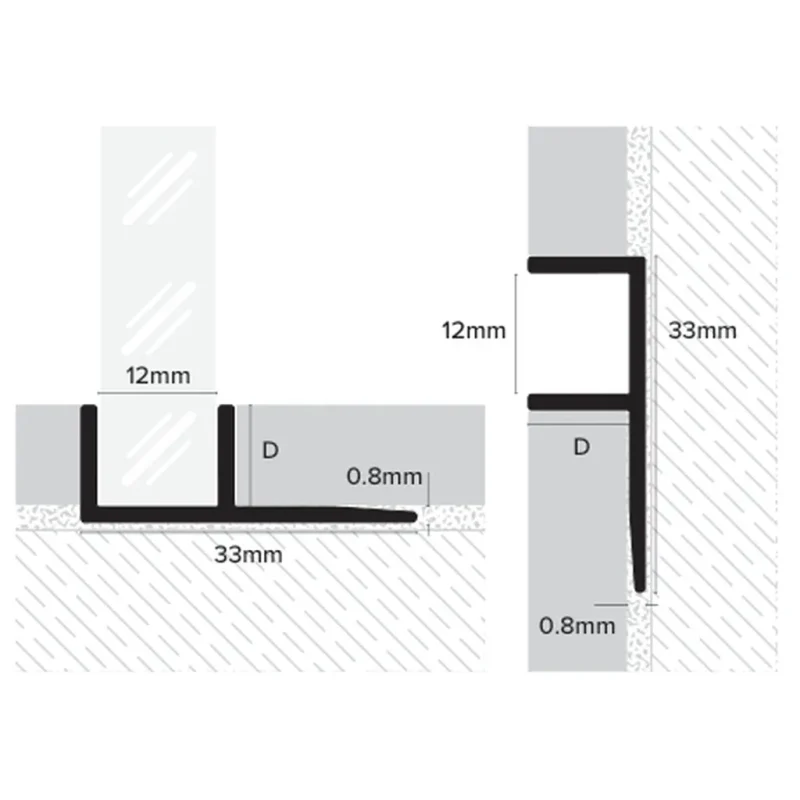

The role of the shadow gap profile

A shadow gap is formed using a specialized metal or PVC profile, often called a bead or channel. This profile is the critical component that ensures a successful result. It is fixed to the underlying structure before the plasterboard is installed. The profile creates a strong, perfectly straight edge for the plaster to finish against, forming the clean, sharp line that defines the gap. Without this profile, achieving a uniform and durable edge would be nearly impossible.

Choosing the right profile material

The material of the profile affects the installation, appearance, and longevity of the detail.

Material | Pros | Cons | Best Use |

|---|---|---|---|

Aluminum | Extremely resilient, creates the sharpest lines, moisture-resistant, can be powder-coated. | Higher material cost, requires a fine-toothed blade for clean cuts. | High-traffic areas like floor-level skirting, trimless door frames, and high-end projects where precision is paramount. |

PVC | Inexpensive, lightweight, easy to cut and handle. | Less rigid than metal, can warp with temperature changes, may not produce as crisp an edge. | Low-impact areas, ceilings, or projects with tight budget constraints. Not recommended for floor level. |

Wood | Can be painted or stained to match other elements. | Susceptible to warping with moisture, does not create as sharp an edge as metal. | Interiors aiming for a warmer, more traditional feel while incorporating a modern detail. |

MDF | Low cost, easy to paint. | Not resilient, easily damaged by moisture or impact, unsuitable for most structural applications. | Dry, low-impact areas for decorative paneling where cost is the primary driver. |

The professional installation process

Creating a flawless shadow gap is not a typical task for a novice. It requires a skilled tradesperson, usually a plasterer with experience in this specific detail. The key steps include:

- Precise Marking: The location of the gap is marked on the wall framing using a laser level to ensure it is perfectly horizontal around the entire room.

- Fixing the Profile: The metal or PVC profile is cut to length and fixed securely to the wall studs or blockwork.

- Installing Plasterboard: The plasterboard sheets are then installed, with the edge sitting flush against the designated flange of the profile.

- Expert Plastering: The plasterer skims the wall, using the edge of the profile as a guide to create a perfectly straight, sharp corner. The joint between the profile and the board is taped and filled to become invisible.

What Are the Downsides of a Shadow Gap?

While visually striking, this detail has practical considerations that must be addressed.

They can collect dust

The recessed channel will inevitably trap dust. This is a common concern, but it is manageable. Regular cleaning with a vacuum cleaner's crevice tool is sufficient to keep the gap clean.

The wall base is less protected

At floor level, a shadow gap leaves the base of the plasterboard wall exposed to impacts from vacuum cleaners, furniture, or foot traffic. This vulnerability is the single most important reason to use a robust profile. An extruded aluminum profile provides significant impact resistance, protecting the plaster edge from chipping and preserving the clean line.

They are more expensive to install

The cost of a shadow gap is higher than that of traditional trims. This is due to the price of the specialized profiles and, more significantly, the increased labor cost. The installation requires a higher level of precision and skill, making it a more time-consuming process for tradespeople. The cost should be viewed as an investment in a bespoke architectural feature.

Risk of cracking from house movement

All buildings experience some degree of movement from settling or thermal expansion and contraction. This can cause hairline cracks to appear along the plaster edge of the gap. This risk is mitigated through proper building framing and professional installation using high-quality, rigid profiles that help stabilize the joint.

Shadow Gaps vs Traditional Trims

Choosing between a modern detail and a traditional trim involves weighing appearance against practical factors.

Feature | Shadow Gap | Traditional Trim (Skirting/Cornice) |

|---|---|---|

Design Appearance | Minimalist, modern, creates a "floating" look. | Classic, decorative, adds visual weight and frames the room. |

Installation | Requires high precision, specialized labor, and must be planned early in construction. | More forgiving of uneven surfaces, can be installed after painting. |

Cost | Higher initial cost due to specialized materials and skilled labor. | Generally lower cost for both materials and installation. |

Maintenance | Recess requires vacuuming; repairs to the plaster edge are complex. | Top edge collects dust; easy to touch up, repaint, or replace if damaged. |

Resilience | Vulnerable to impacts unless a strong aluminum profile is used. | Explicitly designed to protect the wall base from scuffs and knocks. |

Advanced Shadow Gap Techniques

Beyond its basic applications, the shadow gap can be enhanced to incorporate other functions.

Integrating LED lighting

The recess of a shadow gap is an ideal location for concealing LED strip lighting. When installed at the ceiling or floor, this creates a soft, indirect glow that washes across the surface, dramatically enhancing the floating effect. For this application, an aluminum LED profile is essential. It not only provides a clean channel for the light strip but also acts as a heat sink, drawing heat away from the LEDs and significantly prolonging their operational life.

Improving room acoustics

In acoustically sensitive environments, a shadow gap can offer an unexpected benefit. When used at the edge of sound-absorbing wall or ceiling panels, the gap increases the effective surface area of the panels. This phenomenon, known as the "edge effect," allows sound waves to be absorbed from the sides of the panel as well as the front, improving the overall sound absorption efficiency of the treatment.

Frequently Asked Questions

How wide should a shadow gap be?

A typical shadow gap ranges from 10mm to 30mm. A 10-15mm gap creates a subtle, crisp line suitable for most minimalist designs. A wider gap of 20-30mm produces a more pronounced shadow. A gap smaller than 10mm can look like a construction mistake rather than an intentional detail and can be difficult to clean.

Can you retrofit a shadow gap into an existing home?

Retrofitting is possible but highly invasive and costly. It requires cutting away the bottom section of the existing plasterboard walls, installing a new profile, and then re-plastering and refinishing the entire area. It is far more practical and cost-effective to incorporate shadow gaps during a new build or a major renovation where walls are already being replaced or re-plastered.

What is a shadow gap door frame?

A shadow gap door frame creates a trimless opening. Instead of a surface-mounted architrave, a specialized profile is installed around the door jamb. The wall plaster finishes flush to this profile, leaving a clean, narrow recess that outlines the door. This detail requires very rigid framing to prevent cracks from appearing as the house settles.

Do shadow gaps provide any soundproofing?

No, a shadow gap does not provide soundproofing. Soundproofing involves adding mass and decoupling structures to block the transmission of sound between rooms. A shadow gap is a small air channel and will not stop sound. However, it can improve a room's acoustics (sound quality within the space) by enhancing the performance of sound-absorbing panels through the "edge effect."

How do you repair a damaged shadow gap?

Repairing a damaged shadow gap is more complex than patching a simple wall. If the plaster edge is chipped or the profile is dented, the damaged section must be carefully cut out. A new piece of profile is then fitted, and the area is meticulously re-plastered, sanded, and painted to blend with the existing line. This is a task that typically requires a professional for a clean result.

What is the difference between a shadow gap and a reveal?

A reveal is a broader architectural term for the internal surface of an opening, such as the side of a window or doorway between the frame and the outer wall surface. A shadow gap is a specific type of reveal. It is a narrow, linear reveal used intentionally as a design feature to separate two planes, rather than just being a component of an opening.