For a beautiful and durable tile installation, every aspect of the project must adhere to tile industry standards and best practices. This guide focuses on tile backer boards, the unsung heroes that ensure your tiles remain robust and intact over time. Dive into the types, benefits, and essential considerations of tile backer boards, equipping you to choose the right foundation for your tiling needs.

What is Tile Backer Board

Tile backer board is a prefabricated sheet material designed to provide a stable, durable, and often moisture-resistant surface for installing tiles. It serves as an effective alternative to traditional mortar beds and is commonly used on walls, floors, countertops, and in wet areas like bathrooms and showers.

Tile backer boards are composed of materials such as cement, fiber-reinforced gypsum, or coated glass mat. These materials are chosen for their properties like strength, resistance to moisture, and ability to adhere well with tile adhesives.

Unlike plywood or drywall, tile backer boards do not warp, swell, or support mold growth when exposed to moisture, making them well-suited for use in environments like kitchens and bathrooms where humidity and direct contact with water are common.

Advantage of Tile Backer Board

1. Moisture Resistance

Tile backer boards made from cementitious or foam materials offer high resistance to moisture. This attribute is beneficial in wet areas such as bathrooms, showers, and kitchens, helping to protect against water damage and mold growth.

2. Durability

Tile backer boards are known for their durability. They provide a stable and robust surface for tile installation, which helps in maintaining the integrity of the tile work over extended periods.

3. Ease of Installation

Tile backer boards are designed to be easier to install compared to traditional mortar beds. They come in standard sizes and can be easily cut to fit specific measurements, simplifying the installation process for both professionals and DIY enthusiasts.

4. Lightweight Options

Foam tile backer boards are lighter, which eases the burden of handling and can be particularly useful in complex installations or when working in less accessible areas.

5. Insulation Properties

Some tile backer boards, especially those made from foam, also provide insulation properties. These can enhance the performance of underfloor heating systems by reducing heat loss and can contribute to the overall thermal management of a space.

6. Versatility

Tile backer boards are applicable for use on both floors and walls and accommodate various tile materials such as marble, limestone, and granite. Their adaptability extends to fitting into awkward spots and corners, making them an effective solution for diverse tiling projects.

7. Increased Tile Choice

Tile backer boards provide a smooth and flat surface that broadens the range of tile options available for installation. This feature facilitates greater design flexibility and supports the use of larger or heavier tiles, which might not perform well on less stable surfaces.

8. Enhanced Adhesion

Tile backer boards are engineered to foster a robust bond with tile adhesives and grout, which helps maintain the stability of the tiles. This feature is particularly useful for installations that involve heavy or large-format tiles, ensuring that the tiles adhere properly to the surface.

9. Cost-Effective

Though the upfront cost of tile backer boards may vary, they prove to be a cost-effective option over time. This is due to their long-lasting nature, ease of installation, and the protective barrier they provide against environmental factors such as moisture and mold.

10. Low Maintenance

Maintenance requirements for tile backer boards are minimal. Routine cleaning and occasional sealing of the joints are generally sufficient to maintain their condition and functionality over an extended period.

The Main Types of Tile Backer Board

1. Cement Board

Cement board is a prevalent choice for tile backer applications. Composed of cement and reinforcing fibers, it stands out for its durability and water resistance, making it well-suited for both wall and floor applications, particularly in moisture-prone areas like bathrooms and kitchens.

2. Fiber Cement Board

Fiber cement board enhances the traditional cement board formula by incorporating cellulose fibers, which contributes to its robustness. This board is also water-resistant and ensures a solid surface for tile adhesion, commonly preferred for flooring due to its structural qualities.

3. Glass Mat Gypsum Board

Constructed from water-resistant gypsum and reinforced with silicone-treated fiberglass mats, glass mat gypsum board is lighter than cement boards. It's primarily used in moisture-prone installations like tub surrounds. However, it's important to ensure that water does not breach the waterproof surface as it can lead to softening of the board.

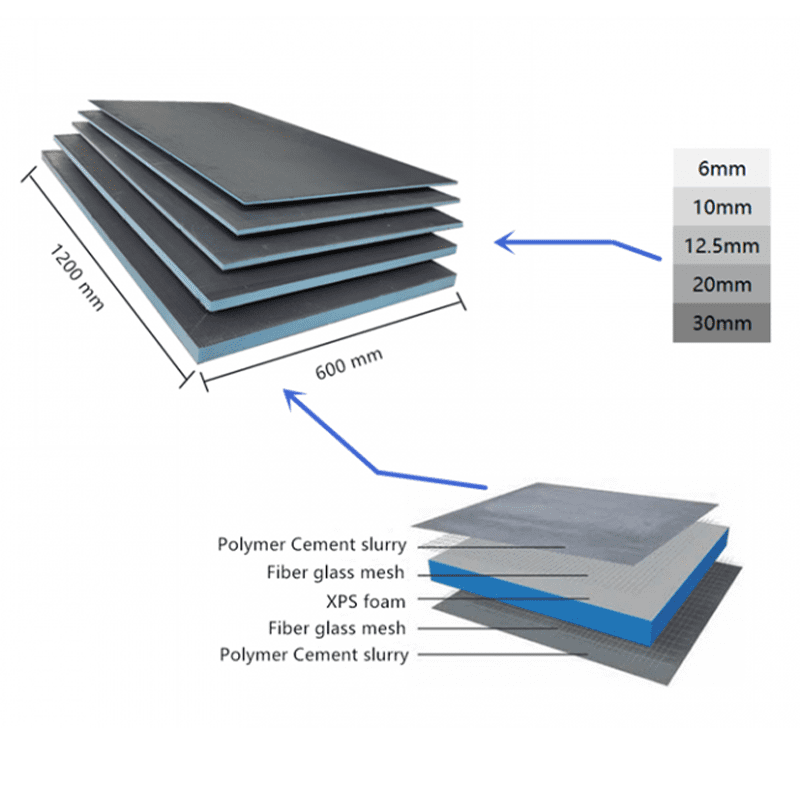

4. Foam Board

Foam-core tile backer boards are distinguished by their lightweight and ease of manipulation, making installation straightforward. They are waterproof and provide insulation, which is advantageous in wet areas and for underfloor heating systems. Attention must be paid to waterproofing seams and fastener penetrations to maintain their efficacy.

5. Water-Resistant Drywall

Often referred to as "green board," water-resistant drywall is suitable for areas exposed to occasional moisture but should not be used where it will face direct, persistent water contact. While less costly, it is more susceptible to damage from extended water exposure compared to more robust tile backer options.

6. Polystyrene-Based Insulation Board

Polystyrene-based boards are characterized by their lightweight, waterproof properties, and excellent insulation capabilities. Commonly used in settings such as wet rooms, pools, and areas equipped with underfloor heating, these boards are reinforced with fiberglass and a polymer resin to enhance their strength and durability.

7. Dimple Mat

Dimple mats feature a unique design of thin polyethylene membranes equipped with a grid of cavities. They function to minimize height buildup while providing a waterproof, uncoupling layer that separates the tile from the subfloor. This configuration is particularly effective in preventing cracks and stabilizing tile installations.

8. Dry-Pack Mortar

Dry-pack mortar is a traditional approach that uses a blend of cement, sand, and water applied over a metal lath to create a flat surface. Although labor-intensive, it remains an effective method for leveling uneven floors and is valued for its robustness in floor preparation.

9. Self-Leveling Underlayment

Self-leveling underlayment is recognized for its quick-setting properties and is used to establish a smooth, even surface ideal for tile setting. Particularly suited for rectifying wavy or uneven floors, this type of underlayment demands meticulous preparation to ensure optimal performance and prevent any issues with seepage.

>> See Our Guide: 14 Tile Underlayments You Need to Know [2024]

How to Choose the Right Backer Board for Tile

Choosing the right backer board for your tile project depends on several factors, including the location of the installation, the type of tiles being used, and specific project requirements.

1. Location and Moisture Exposure

- Wet Areas (Bathrooms, Showers, Kitchens):

- Cement Board: Known for its durability and water resistance, ideal for environments that encounter moisture regularly.

- Fiber Cement Board: Incorporates wood fibers for reinforcement, sharing similar water-resistant properties.

- Foam Board: Notable for being lightweight and waterproof, excellent for ease of installation and cutting.

- Glass Mat Gypsum Board: Offers mold resistance and a moisture barrier, suited for damp locations like tub surrounds.

- Dry Areas (Living Rooms, Hallways):

- Water-Resistant Drywall (Green Board): An economical choice for areas with occasional moisture; however, it lacks the durability for wet exposure.

- Standard Drywall: Appropriate for completely dry environments but generally not recommended for areas where tiles are expected to endure moisture.

2. Tile Type and Size

- Large or Heavy Tiles:

- Cement Board: Robust and stable, capable of supporting heavier tiles without compromise.

- Fiber Cement Board: Offers a solid surface that ensures tiles remain securely in place.

- Smaller or Lighter Tiles:

- Foam Board: Its lightweight nature makes it ideal for smaller tiles, providing ease during the installation process.

- Glass Mat Gypsum Board: Preferred for its manageability and suitability for light tile applications.

3. Ease of Installation

- Ease of Cutting and Handling:

- Foam Board: The easiest to manage and cut, often preferred for quick adjustments.

- Glass Mat Gypsum Board: Simplifies the cutting process, reducing installation time.

- Durability and Strength:

- Cement Board: Tops the chart in durability, making it suitable for high-impact areas.

- Fiber Cement Board: Maintains durability but requires more care during installation due to its brittleness.

4. Insulation and Thermal Properties

- Foam Board: Excellent insulator, particularly beneficial for projects incorporating underfloor heating.

5. Cost

- Water-Resistant Drywall: Cost-effective for dry installations, offering a basic solution for moisture-occasional areas.

- Cement Board and Fiber Cement Board: These options represent a mid-range price point, providing a balance between cost and performance.

- Foam Board and Glass Mat Gypsum Board: While potentially more costly, they deliver specific benefits such as lightweight handling and enhanced moisture resistance.

Professional Recommendations

Based on the factors above, here are some recommendations:

- For Wet Areas (e.g., Bathrooms, Showers):

- Primary Choice: Cement Board or Fiber Cement Board, both of which offer robust water resistance and durability.

- Alternative: Foam Board is lighter and easier to install, suitable for less demanding applications.

- Consideration: Glass Mat Gypsum Board, beneficial for its mold resistance and easier handling.

- For Dry Areas (e.g., Living Rooms, Hallways):

- Primary Choice: Water-Resistant Drywall, known for its affordability and simplicity.

- Alternative: Standard Drywall, adequate where moisture is not a concern.

- For Underfloor Heating:

- Primary Choice: Foam Board due to its superior insulation properties.

We are a professional tile backer boards manufacturer and supplier. If you have any demand for purchasing backer boards, please feel free to contact us.

FAQs about Tile Backer Board

Is tile backer board waterproof?

Tile backer board is designed to be moisture resistant rather than fully waterproof. While it significantly outperforms plasterboard and plywood in wet areas due to its rot-resistant properties, its waterproof capabilities can vary depending on the type of backer board.

Cement-based backer boards, for example, are highly moisture-resistant and are ideal for wet rooms and bathrooms. However, even these boards require proper sealing, especially at joints and corners, to fully prevent water penetration. For absolute waterproofing, a waterproof membrane applied over the backer board is recommended.

What is the difference between cement board and backer board?

The primary difference between cement board and other types of tile backer board, such as foam backer board, lies in their composition and strength. Cement board is made from cement and reinforcing fibers, which makes it extremely durable and ideal for providing structural support in tile installations. It is heavier and harder to cut but offers superior rigidity, making it suitable for floors and walls where heavy tiles will be installed.

Foam backer boards are lighter and easier to cut, making installation quicker. However, they provide less structural support and might require additional reinforcement when used under heavier tiles or in larger installations.

Can I tile directly onto a tile backer board?

Yes, you can tile directly onto a tile backer board, but it is essential to prepare the surface properly to ensure a lasting installation. Before laying the tiles, apply a layer of thin-set mortar directly to the backer board using a notched trowel to create a strong, even base.

This adhesive layer helps to bond the tiles securely and prevents any movement that could lead to cracks or loosening over time. Ensure that the mortar is compatible with both the type of tile and the backer board being used.

Can I just screw down the backer board?

To properly install a backer board, it should be screwed down to the subfloor or wall studs. Use cement board screws spaced every 6 to 8 inches across the entire board. The screws should be positioned at least 1/2-inch from the edge to prevent cracking but no more than 2 inches away. Drive the screws so that their heads are slightly below the surface of the backer board to create a smooth, even surface for tiling.

Do I need adhesive for backer board?

In dry areas, the joints of the backer board must be sealed with a specialized mesh tape to prevent cracking. In wet areas, such as around bathtubs or shower stalls, both mesh tape and a waterproof tile adhesive or thin-set mortar should be used to seal and bond the joints.

This additional layer of adhesive helps to fully secure the backer board and provides an extra moisture barrier, ensuring the longevity and durability of the installation in moisture-prone areas.