Do you know what floor coving is used to? Welcome to read this informative guide where you can learn about the various advantages of floor coving, and its significant importance in modern commercial and industrial construction. Whether you are a construction worker or a contractor, you will find it informative and beneficial.

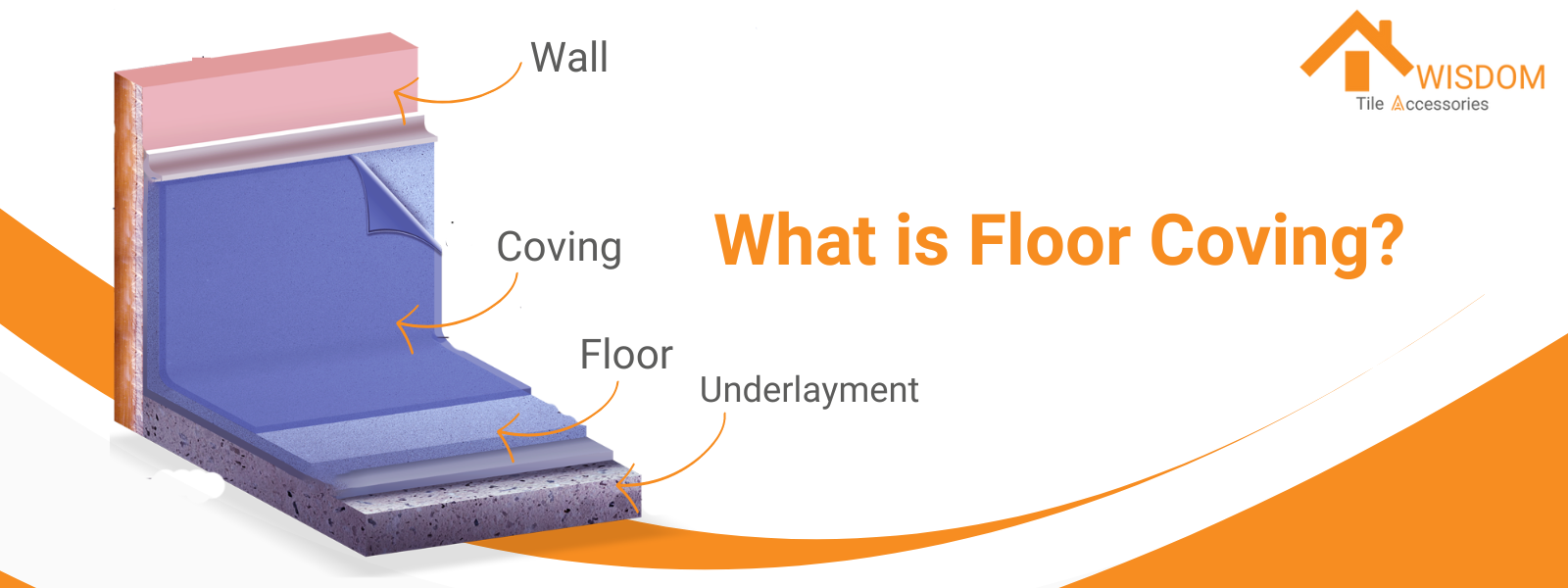

What is Floor Coving?

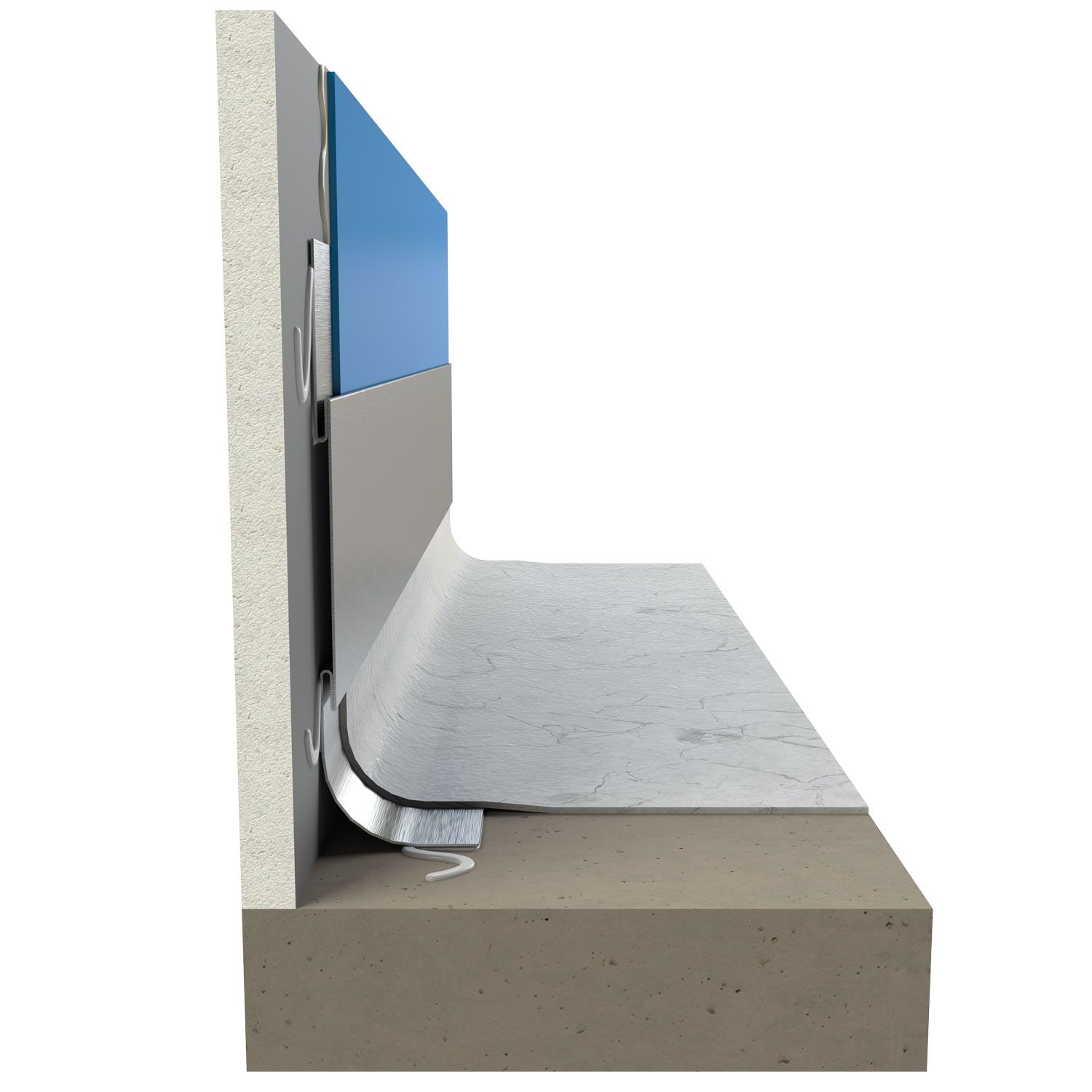

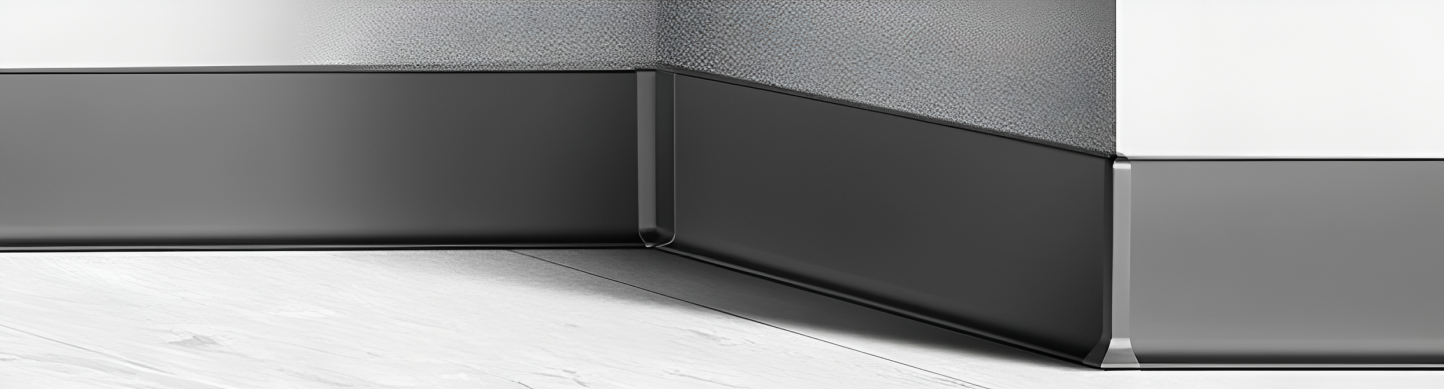

Floor coving is a critical construction technique that involves installing curved or angled barriers, known as coves, at the crucial intersection between the floor and the wall. Utilizing a standard rounded 45-degree angle that slopes upward, floor coving eliminates the sharp angle typically found at this juncture. This innovative method not only enhances the aesthetic appeal of a space but also plays a pivotal role in maintaining its structural integrity and cleanliness.

What is Floor Coving Used For?

Floor coving is used to significantly improve the hygiene and safety of any space by preventing the accumulation of dirt, debris, and water along the edges and corners of rooms. This is particularly essential in environments where cleanliness is paramount, such as in food processing plants, healthcare facilities, and commercial kitchens. By ensuring that these hard-to-reach areas are easier to clean, floor coving contributes to a more sanitary environment, reducing the risk of contamination and facilitating maintenance tasks.

Moreover, floor coving serves to protect the walls from moisture damage and the impacts from equipment and foot traffic, thereby preserving the structural integrity of the building. The seamless transition created by coving between walls and floors not only prevents the buildup of harmful substances but also adds to the visual appeal of the area, providing a finished look that can complement the overall design of the space.

In the modern construction industry, floor coving has become an indispensable component. As the demand for environmental safety increases, using floor coving to maintain floor hygiene has gradually become a mainstream approach.

The International Building Code (IBC) in section 1209.2.1 specifies: "In other than dwelling units, toilet, bathing, and shower room floor finish materials shall have a smooth, hard, nonabsorbent surface. The intersections of such floors with walls shall have a smooth, hard, nonabsorbent vertical base that extends upward onto the walls not less than 4 inches (102 mm)."

Tips:

The Wall Base described in the IBC corresponds to Cove Base, consistent with Floor Coving.

If you observe closely, it's not difficult to notice that almost all dining, commercial, and industrial buildings utilize floor coving. Rather than being a trend, it has developed into a standard.

Therefore, whether for contractors or construction personnel, it is essential to understand the importance of floor coving.

Next, let's analyze the benefits of floor coving from four perspectives.

Why Floor Coving is Important for Industrial and Commercial Floor?

Reason 1: Improved Facility Hygiene

When it comes to hygiene, food safety becomes a paramount concern. So, what is coving in food safety? As you can see, coving serves as a semi-circular transition at the junction of the floor and the wall, which effectively prevents liquids and residues from falling into the gaps. More over, it will also reduce the breeding of bacteria.

According to the Approved Floor Materials Code provided by CPD, the following is a summary of floor coving in food safety.

Floor Material Type | Criteria/Requirements | Approved Options |

|---|---|---|

Quarry and Ceramic Tile |

|

|

Epoxy and Resin-based Flooring Systems |

|

|

Commercial Grade Sheet Vinyl Flooring |

|

|

Cell |

|

|

Unapproved Flooring Materials |

|

|

Exceptions |

| Cell |

Metal Cove Base for Walk-in Coolers/Freezers |

|

|

Reason 2: Streamlined Cleaning Efficiency

Coving creates a surface that is very easy to clean and maintain. This curved surface enhances the efficiency of cleaning personnel. For example, compared to floors without a cove base, cleaning personnel will no longer need to worry about corners that cannot be thoroughly disinfected.

Due to the absence of gaps, some cleaners and chemicals also do not penetrate into the floor, extending the floor's lifespan.

It is obvious that cleanliness and hygiene go hand in hand. Whether in the food industry or other public places, floor coving provides indispensable safety assurance. The improvement in cleaning efficiency not only reduces labor costs but also brings about safety benefits for people.

Reason 3: Enhanced Wall Protection

In addition, floor coving is used to protect walls. The upper part effectively shields the walls from wear and scratches. In environments with large quantities of stored items, such as warehouses, the role of floor coving is particularly evident.

When people use carts, collisions with walls are common, leading to surface cracks or damage. After installing cove base, this special curved surface provides an effective protective layer for the bottom of the walls, mitigating the impact force.

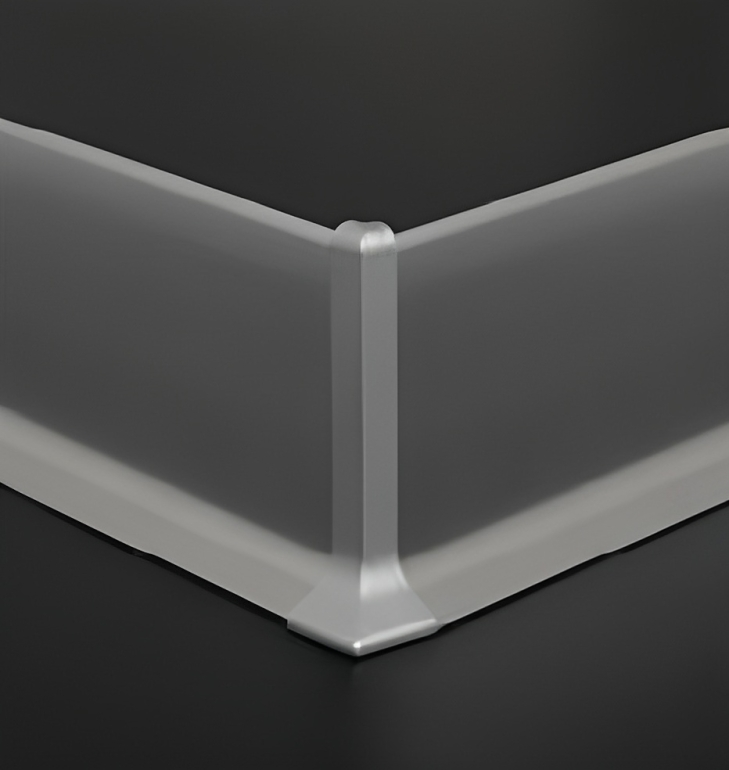

Reason 4: Versatility in Design Options

In modern construction, besides considering safety performance, people also consider aesthetics and artistry. Floor coving serves a decorative purpose, achieving a seamless transition from the wall to the floor.

The variety in texture, color, and patterns enriches the diversity of decorating styles, ensuring that the overall style does not become overly monotonous. This aligns with engineers' vision for architectural design, providing people with the most beautiful environmental experience.

Where You Should Install Cove Base?

Food Production Environments

- Food Processing Facilities: Prevent contamination by installing cove base, creating a seamless transition for efficient cleaning and hygiene.

- Breweries and Beverage Facilities: Safeguard against liquid spills with cove base, ensuring a clean and damage-resistant environment.

- Dishwashing Rooms: Enhance cleanliness by installing cove base, providing a protective barrier against water and chemicals.

- Commercial Kitchens: Ensure safety and compliance by preventing water, grease, and debris accumulation with cove base.

Chemical and Medical Environments

- Chemical Laboratories: Protect walls from chemical spills with cove base, maintaining a safe and durable laboratory environment.

- Pharmaceutical Facilities: Install cove base for easy cleaning and infection control in sterile environments.

- Healthcare Settings: Safeguard against contamination by installing cove base, facilitating stringent cleaning procedures.

Other Industrial Wet Environments

- Manufacturing Plants: Prevent water-related wear and tear with cove base installation, ensuring facility durability.

- Facilities with Water Usage: Install cove base for durability and moisture resistance in areas with frequent water-based processes.

What is the Difference between Coving and Skirting Board?

Skirting boards are types of trim used to finish off the bottom of walls. Similar to floor coving, they serve similar purposes but have different characteristics and uses.

Material

Skirting boards are typically made of wood, laminate, vinyl, or metal. They consist of two parts: the base, which is attached to the floor, and the top, which can be finished with any material.

On the other hand, cove base is usually made from either rubber, stone or vinyl. Rubber cove base is preferred as it doesn’t shrink and is more scuff resistant. It can be made in seamless rolls or in lengths, usually 4’ long. Some new types of cove base are made in either 6’ or 8’ lengths depending on the producer.

Design

Floor coving connects to the bottom of the walls but primarily adheres closely to the surface of the floor. The junction has a curved shape, typically extending upward to the upper part of the wall.

On the contrary, baseboards can be designed in a straight line or with decorative patterns, placing more emphasis on protecting the bottom of the walls.

Choose the Right One for Your Construction Project

Whether choosing floor coving or baseboards, their main purpose is to ensure cleanliness and hygiene in indoor environments. As for their decorative function, it depends on individual aesthetics and architectural design styles.

I'm glad to introduce you to knowledge in the field of engineering and construction. If you have any questions, feel free to reach out at any time.

FAQ about Floor Coving

How to install cove base?

To install cove base, follow these steps:

- Prepare the wall by ensuring it is smooth, clean, and dry.

- Measure and cut the base to size using a utility knife.

- Apply cove base adhesive to the back of the base.

- Position the base on the wall and press it firmly in place.

- Use a seam roller to ensure good adhesive transfer between the base and the wall.

- For corners, use a top set gouge for outside corners and deluxe dividers for inside corners.

- Use the appropriate tools, such as a notched spreader, seam roller, and cove base nozzle, to facilitate the installation.

What is another name for cove base?

Another name for cove base is "wall base”, which is used to protect wall and floor.