Do you back butter your tile? In the realm of tile installation, the technique known as "back buttering" is both a topic of technical necessity and a subject of debate among professionals. This method, which involves the application of a thin layer of adhesive to the back of tiles before installation, raises several questions: Is it an indispensable step for ensuring the longevity and durability of tile work, or merely an additional measure that can be bypassed under certain circumstances?

What is Back Buttering

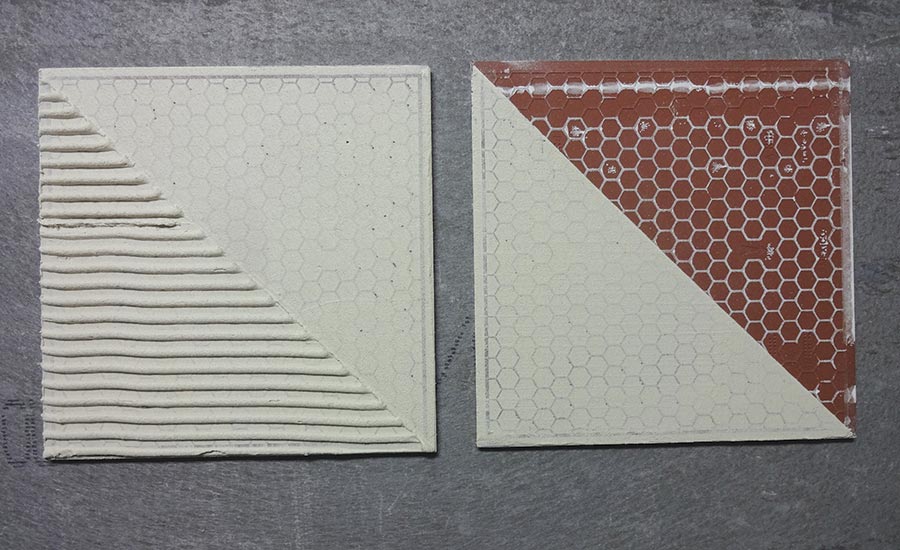

Back buttering is a tile installation technique designed to enhance the durability and effectiveness of the bond between tile and its underlying surface. This method involves the application of a bonding agent—commonly thin-set mortar—directly onto the back side of tiles prior to their placement. The primary rationale behind this approach is to ensure a more robust adhesion and to address several challenges inherent in tile installation.

The Science Behind the Technique

At its core, back buttering compensates for the natural imperfections and variability found in tile and substrate surfaces. Tiles, especially those made from natural stone, can have irregular backs that result in uneven adhesive coverage when only the substrate is coated with mortar. By applying mortar directly to the tile, back buttering creates a uniform adhesive layer that can fill these gaps, leading to a more secure and stable installation.

Addressing Tile Warpage

Tile warpage is a common issue, particularly with larger format tiles. Warpage refers to the slight bending or curving of tiles that can occur during the manufacturing process. When such tiles are installed without back buttering, the unevenness can lead to poor contact with the adhesive, creating weak spots. Back buttering allows for the mortar to fill in the low points on the back of the tile, ensuring that when pressed onto the substrate, the tile achieves maximum contact and adhesion.

Enhancing Mortar Bond Strength

The process of back buttering also enhances the bond strength between the tile and the mortar. By applying a fresh mortar layer directly to the tile, the installer can "key in" the mortar, creating a mechanical bond that is significantly stronger than what could be achieved by mortar application to the substrate alone. This is particularly important in areas subjected to heavy traffic or moisture, where the integrity of the tile installation is crucial for longevity and safety.

Key Considerations

- Material Type: While all tiles can benefit from back buttering, it's especially recommended for natural stone and large format tiles due to their size, porosity, and potential for warpage.

- Adhesive Selection: The choice of adhesive is critical. A high-quality thin-set mortar suitable for the specific tile material and installation environment will ensure optimal results.

- Technique: Achieving an even, thin coat of mortar on the back of the tile requires skill and practice. Using the flat side of the trowel ensures uniform coverage and thickness.

The Debate: To Back Butter or Not?

The discussion around whether to back butter tiles during installation is not just a matter of preference but a nuanced debate among professionals in the field. This discourse is fueled by varying experiences, the evolution of materials, and the diverse conditions under which tile installation occurs.

Perspectives and Practices

On one side of the debate, proponents of back buttering argue for its undeniable benefits, particularly in enhancing the durability and adherence of tiles to their substrate. They point to the technique's ability to compensate for irregularities in both the tile and the substrate surface, ensuring a more uniform and reliable bond. This school of thought often highlights the critical nature of back buttering when working with materials prone to absorption or when dealing with larger format tiles, where even minor discrepancies in surface contact can lead to significant issues down the line.

Conversely, skeptics of back buttering question its necessity in every installation scenario. With advancements in adhesive technologies and trowel designs, some argue that achieving optimal coverage and bond strength is possible without the additional step of back buttering, especially for ceramic and porcelain tiles. This perspective emphasizes efficiency and cost-effectiveness, suggesting that back buttering may represent an unnecessary labor and material expense in situations where modern adhesives provide sufficient bonding strength on their own.

Key Factors Influencing the Decision

- Tile Type and Size: The nature of the tile—whether it's ceramic, porcelain, or natural stone—and its dimensions play a significant role in determining the need for back buttering. Larger and more porous tiles, in particular, often require the extra assurance of back buttering.

- Substrate Condition: The condition and type of substrate also influence the decision. Uneven or highly porous substrates may necessitate back buttering to ensure full coverage and support.

- Installation Environment: Areas subjected to high moisture levels, such as bathrooms and kitchens, or high traffic may benefit more from back buttering due to the increased demand for a durable bond.

- Professional Judgment: Ultimately, the decision often comes down to the professional judgment of the installer, who must weigh the specifics of each project against their expertise and experience.

The ongoing debate about back buttering underscores the complexity of tile installation as an art and science. While there's no one-size-fits-all answer, the choice to back butter should be informed by a comprehensive understanding of the materials, the installation environment, and the long-term performance goals of the project.

Methodologies: Floating and Buttering

In the intricate craft of tile installation, methodologies like floating and buttering play pivotal roles in achieving a flawless finish and enduring durability. These techniques, while distinct in their application, share the common goal of optimizing tile adhesion and compensating for substrate imperfections.

Floating: Creating a Level Base

The floating technique is employed to prepare an even and level substrate before tile placement. This method involves applying a layer of mortar or adhesive to the substrate and then 'floating' it out—smoothing and leveling it with tools such as a straight edge or trowel. The primary objective is to create a flat surface that can support tile installation, especially crucial in instances where the substrate itself presents irregularities, such as dips or humps.

Floating is particularly beneficial in renovations or when working over an existing floor that may not be perfectly level. It ensures that the tiles will lay flat, preventing issues like lippage (variations in tile height) which can compromise both aesthetics and safety.

>> See What is Tile Lippage?

Buttering: Ensuring Individual Tile Adhesion

Buttering, more specifically back buttering, focuses on the application of adhesive to the back of individual tiles. This method enhances the tile's adhesion to the substrate by ensuring a thorough and consistent coverage of mortar, directly addressing potential voids and promoting a stronger bond. As discussed, back buttering is especially recommended for tiles that are large, porous, or have irregular backs.

Combining Techniques for Optimal Results

In many high-quality tile installations, floating and buttering are combined to achieve optimal results. Floating prepares a perfectly level and smooth substrate, while buttering ensures that each tile is fully supported and bonded to the substrate. This dual approach is particularly advantageous in scenarios demanding the utmost in durability and finish quality, such as in high-traffic areas or where moisture exposure is a concern.

The decision to employ these methodologies often hinges on factors such as the type of tile, the condition of the substrate, and the specific requirements of the project. For example, large format tiles or tiles being installed over uneven surfaces may benefit significantly from the combined use of floating to level the substrate and buttering to ensure a solid bond.

In essence, the integration of floating and buttering techniques stands as a testament to the nuanced considerations and expert craftsmanship that define professional tile installation. By judiciously applying these methods, tile installers can navigate the challenges posed by varied installation environments and material characteristics, ensuring that each project not only meets but exceeds expectations.

What Happens if You Skip Back Buttering?

Opting out of back buttering in tile installation might seem like a shortcut or a time-saver, but it's essential to understand the potential consequences of bypassing this step. While not every scenario strictly requires back buttering, omitting it when it's recommended or necessary can lead to several issues that compromise the integrity, appearance, and longevity of the tile work.

Reduced Bond Strength

The primary concern with skipping back buttering is the potential for reduced bond strength between the tile and the substrate. Back buttering enhances the contact area between the tile and the mortar, leading to a stronger, more uniform bond. Without this additional layer, the risk of a weaker bond increases, particularly with larger, more porous tiles or on uneven substrates. This can result in tiles that are more prone to cracking, shifting, or becoming loose over time.

Increased Likelihood of Voids

Back buttering serves to fill any voids on the back of the tile, ensuring that the entire surface is supported by the adhesive. Skipping this step can leave voids unfilled, which compromises the tile's stability and increases the risk of breakage under pressure. This is especially crucial in high-traffic areas or where tiles are subject to heavy loads.

Heightened Risk of Tile Lippage

Uniform adhesive application through back buttering helps maintain a level surface across tiles. Without back buttering, variations in adhesive thickness or coverage can lead to lippage—where the edges of adjacent tiles are not flush. Lippage not only detracts from the finished look of the installation but can also pose a tripping hazard.

Challenges with Large Format Tiles

The importance of back buttering becomes even more pronounced with large format tiles. These tiles require a more significant bond to support their weight and size, and any inconsistencies in the adhesive layer can lead to issues with adhesion and flatness. Skipping back buttering in these cases can result in an unstable installation that's more likely to suffer from problems down the line.

Potential for Moisture Penetration

In areas exposed to moisture, such as bathrooms and kitchens, back buttering adds an extra layer of protection against water infiltration. Without it, the risk of moisture reaching the substrate increases, potentially leading to mold growth, tile detachment, or substrate damage.

While the decision to back butter should be informed by the specifics of each project, understanding the potential ramifications of omitting this step is crucial. In many cases, the additional time and effort required for back buttering are negligible compared to the benefits it offers in terms of durability, appearance, and the overall success of the tile installation.

Thickness and Technique

In the realm of tile installation, the nuances of thickness and technique, particularly in relation to back buttering, play critical roles in the overall success and longevity of the finished surface. Understanding how to properly execute back buttering, including how thick the adhesive layer should be and the technique used to apply it, is pivotal for ensuring optimal adhesion and performance.

Determining the Ideal Thickness

The thickness of the mortar layer applied in back buttering should be carefully calibrated to match the tile's requirements and the specific conditions of the installation. Generally, a thin, even layer is sufficient to improve adhesion without introducing problems associated with excessive thickness, such as prolonged drying times or difficulties in achieving a level installation.

For standard tiles, a thin layer approximately 1/16 to 1/8 inch thick is often adequate. This thickness ensures that the mortar fills any voids on the tile's back without creating excessive bulk that could hinder the tile's ability to lie flat against the substrate. However, for larger format tiles or those with significant texture or irregularities on the back, a slightly thicker layer may be necessary to ensure full coverage and support.

>> See Standard Tile Thickness

Mastery in Technique

The technique used in back buttering is as important as the thickness of the mortar layer. The goal is to achieve a consistent, uniform coverage across the entire back of the tile. This is typically accomplished using the flat side of a trowel to spread the mortar, applying even pressure to ensure the layer is uniform in thickness.

Key techniques include:

- Keying In: Initially, press the mortar into the back of the tile to ensure it makes good contact with the surface. This helps in creating a mechanical bond that is crucial for strong adhesion.

- Directional Troweling: After keying in, use the trowel to spread the mortar in one direction. This helps in achieving a uniform thickness and aids in the removal of air pockets, which can compromise the tile's adherence to the substrate.

Adjusting Technique Based on Tile Type

The specific characteristics of the tile being installed may require adjustments to the back buttering technique. For example, porous tiles such as natural stone may absorb mortar more quickly, necessitating a slightly thicker layer or a more vigorous keying-in process to ensure adequate coverage. Conversely, dense tiles like porcelain may require a more delicate touch to avoid applying too much mortar, which could lead to issues with leveling and alignment.

Back Buttering vs. Back Troweling

In the discourse on tile installation techniques, the comparison between back buttering and back troweling is essential for understanding their respective roles and benefits. While both practices aim to enhance tile adhesion and compensate for surface irregularities, they are distinct in their application methods and specific purposes.

Back Buttering: Enhancing Tile-to-Adhesive Contact

Back buttering, as previously detailed, involves applying a thin layer of adhesive directly to the back of each tile before installation. This technique is particularly beneficial for ensuring that the adhesive fully contacts the tile, especially in cases of larger, more irregular, or porous tiles. Back buttering facilitates a stronger bond by effectively filling in any gaps or voids on the tile's back surface, promoting a more secure and durable installation.

Back Troweling: Preparing the Substrate

Conversely, back troweling refers to the application of adhesive onto the substrate rather than the tile. This method involves using a notched trowel to spread the adhesive in a way that creates uniform ridges. The primary objective of back troweling is to prepare a consistent adhesive bed that can accommodate the tile, ensuring that when the tile is pressed down, the adhesive spreads evenly, collapsing the ridges and creating a strong bond with full coverage.

Comparing the Techniques

- Application Focus: Back buttering focuses on the tile itself, ensuring it has an even coat of adhesive. Back troweling, however, is concerned with preparing the substrate to receive the tile.

- Purpose and Benefit: While both techniques aim to improve adhesion, back buttering is particularly useful for addressing tile-specific issues like porosity and irregularities. Back troweling, on the other hand, is essential for achieving an even adhesive layer on the substrate, facilitating optimal tile alignment and bonding.

- Usage Scenarios: Back buttering is often recommended for tiles that are large, porous, or have a significant degree of irregularity. Back troweling is a standard practice for almost all tile installations, ensuring the substrate is adequately prepared to support the tile.

Integrating Both Techniques for Optimal Results

In many high-quality installations, both back buttering and back troweling are employed to maximize the bond between tile and substrate. This combined approach addresses potential adhesion challenges from both sides of the installation, ensuring that the adhesive fully engages with both the tile and the substrate. By meticulously preparing both surfaces, installers can significantly reduce the risk of installation failures, such as tile cracking or debonding.

Specific Considerations

The decision to employ back buttering as part of the tile installation process is multifaceted, involving an assessment of the tile type, substrate condition, and the specific demands of the installation environment.

Tile Type and Size

- Natural Stone Tiles: Given their porosity and potential for irregularities, natural stone tiles often require back buttering to ensure full adhesive contact and to prevent issues like cracking or debonding.

- Large Format Tiles: The size of these tiles increases the likelihood of voids between the tile and the substrate. Back buttering helps in achieving a more consistent adhesive layer, reducing the risk of tile failure.

- Ceramic and Porcelain Tiles: While generally less porous, the decision to back butter these tiles may depend on their size and the flatness of the installation surface. Porcelain tiles, especially, benefit from back buttering due to their dense nature, which can make achieving a strong bond more challenging.

Substrate Condition

- Level and Smoothness: Uneven or textured substrates may require additional preparation, including back buttering, to ensure that tiles adhere properly and lay flat.

- Moisture Exposure: In areas with high moisture exposure, such as bathrooms or kitchens, back buttering can provide an extra layer of security against tile lifting or water damage.

Installation Environment

- High Traffic Areas: Floors in entryways or commercial spaces, where there is significant foot traffic, benefit from the enhanced durability that back buttering provides.

- Wet Areas: Showers, backsplashes, and outdoor installations, where water exposure is frequent, require careful consideration of both tile and adhesive selection, with back buttering often recommended to ensure a waterproof seal.

Professional Judgment

- Installer Experience: The decision to back butter tiles often rests on the professional judgment of the installer, who must assess the specific demands of each project.

- Project Requirements: Each installation has unique aesthetic and performance requirements. Installers need to consider these alongside best practices to determine the most appropriate techniques to employ.

Quick Questions & Answers

Are you supposed to back butter tile?

Yes, back buttering tile is recommended, especially for natural stone and large format tiles. This technique involves applying a thin layer of adhesive to the back of the tile before installation, enhancing the bond strength and compensating for any irregularities on the tile surface or substrate. While not mandatory for all tile types, back buttering is beneficial for ensuring a durable and even installation.

What is the floating and buttering method?

The floating and buttering method combines two techniques to prepare the substrate and tiles for installation. Floating refers to leveling the substrate with mortar to create a smooth, even surface. Buttering, specifically back buttering, involves applying adhesive to the back of each tile. Together, these methods ensure a strong bond and a flat, uniform tile surface, crucial for high-quality tile installations.

What can I use to stick tile back on?

To reattach a tile, use a thin-set mortar or a tile adhesive designed for the tile material you are working with. Ensure the back of the tile and the substrate are clean and free of debris before applying the adhesive. Spread a thin layer of adhesive on the substrate or back butter the tile, then press firmly into place, ensuring full contact and support.

Can you put adhesive on the back of the tile?

Yes, applying adhesive on the back of the tile, known as back buttering, is a common practice that enhances the bond between the tile and its substrate. This method is particularly useful for large format or irregularly shaped tiles, ensuring they adhere securely and evenly to the surface.

What happens if you don't back butter tile?

Skipping back buttering can lead to inadequate adhesive coverage, especially with large or irregularly shaped tiles. This may result in weak spots, potential for tile lifting, and an increased risk of cracking under pressure or over time. While not always necessary for smaller ceramic tiles, back buttering is crucial for ensuring a strong, lasting bond for certain types of tile.

How thick to back butter tile?

The ideal thickness for back buttering is typically between 1/16 inch to 1/8 inch. This thickness ensures that the adhesive fills any voids on the tile's back without being so thick that it creates leveling issues or extended drying times. Adjustments may be necessary based on the tile's size and the substrate's condition.

Back buttering vs. back troweling: What's the difference?

Back buttering involves applying adhesive directly to the back of the tile to ensure full coverage and strong adhesion. Back troweling, on the other hand, refers to the technique of applying adhesive to the substrate in a manner that prepares it to bond with the tile. Both practices aim to enhance the installation's durability but focus on different aspects of the tile and substrate preparation.

Do you have to back butter porcelain tile?

While not always mandatory, back buttering porcelain tiles is advisable to ensure optimal adhesion, especially for larger format tiles or when installing over uneven substrates. Porcelain tiles are denser and less porous, which can make achieving a strong bond more challenging without back buttering.